The tuning fork level switch is also often called the tuning fork level meter or the tuning fork level controller, mainly because the tuning fork level meter appears in different links in industrial production. Tuning fork level switch is a kind of level switch.

What is a point level sensor ?

Point level sensor can measure both level and solid. The vibrating material level switch is detected by amplitude, while the vibrating liquid level switch is detected by frequency, and most of the material level switch products are one product to realize the detection of material level and liquid level. In this way, the product can measure solid and liquid simultaneously within a certain range, but in principle, the reliability of the product is very poor, the measurement results are unstable, and it is easy to cause false alarms.

The level switch adopts two different design principles for the measurement of solid and liquid, which makes the product performance more reliable and the measurement more stable.

What is a tuning fork level switch?

Tuning fork level switch is also called tuning fork level switch, tuning fork level meter or tuning fork level controller. Tuning fork level switch is a kind of vibration type level switch. It mainly uses the resonance principle of tuning fork to measure the level state. Its unique fork body design and its inherent vibration characteristics can ensure the automatic cleaning function of the tuning fork and prevent it to the greatest extent. hanging material. It adopts single-point control of measuring range, high sensitivity, strong corrosion resistance and other characteristics.

What is the working principle of vibrating level switch?

The working principle of vibrating level switch:

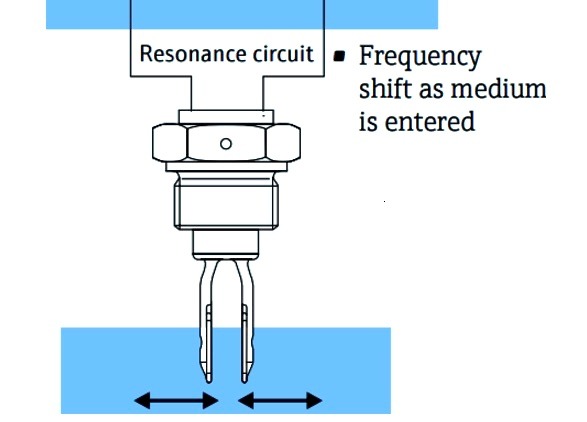

The probe of the vibrating level switch is a vibrating body, and the vibrating body can be in the shape of a tuning fork or a round rod. Generally, piezoelectric devices are used to realize the drive and detection of the probe vibration. When the vibration probe is not in contact with the material, the vibration probe will vibrate freely at the resonance frequency. When the vibration probe is in contact with the material to be measured, due to the resistance or damping effect of the material, the vibration probe’s amplitude will be significantly reduced or even stopped, and the vibration frequency will also be significantly reduced. The amplitude and frequency of the output signal of the piezoelectric detection device also decrease or decrease accordingly, and the change of the detection signal is detected and analyzed by the circuit and a switch signal is output. The vibrating level switch is divided into a tuning fork level switch, a tuning fork level switch and a vibrating rod level switch.

Types of vibrating level switch

➤What is a vibrating level switch?

Vibration level switch is the most common level switch, which is subdivided into three types: tuning fork solid level switch, tuning fork liquid level switch and vibrating rod solid level switch.

Turning fork solid level switch VS Turning fork liquid water level switch VS Vibrating rob level switch

1. Tuning fork solid powder level switch

The vibrating fork body (also called fork wings) of the tuning fork level switch is longer and wider, with a typical size of 150mm long, 22mm wide and 4mm thick. It is a solid level switch specially used for measuring powder and fine particles. At present, the lowest material density that can be measured is as low as 0.008g/cm³, which is especially suitable for ultra-low density material level measurement, with wide adaptability and high reliability. Suitable for all kinds of powder or fine particles, such as: coal ash, dust, fine sand, chemical raw materials, flour, salt, grain, beans, etc. Mainly used in environmental protection, chemical industry, electric power, food, medicine and other industries.

2. Tuning fork liquid water level switch

The vibrating fork body of the tuning fork level switch is generally small and short. The typical tuning fork length is only 40mm. It is not only suitable for liquid level measurement in containers, storage tanks and tanks, but also for liquid level measurement in conduits. At the same time, based on the design principle of detecting the change of vibration frequency when the fork body is immersed in the medium, the product is especially suitable for complex measurement occasions with foam, air bubbles, viscous liquid and vibration interference. The lowest density of measurable liquids is 0.5g/cm³. It can measure tap water, hydrogen peroxide, hydrochloric acid, sulfuric acid, nitric acid, acid-base liquid, industrial wastewater, syrup, liquid medicine and other liquids. Mainly used in water conservancy, chemical industry, environmental protection, food, medicine and other industries.

3. Vibrating rod level switch

The vibrating probe of the vibrating rod level switch is generally tubular, with a single-tube structure and a double-tube structure embedded inside and outside. The design and production process of the double-pipe structure is far more difficult than the design of the single-pipe structure, but the reliability and life of the product based on the double-pipe structure are much higher than those of the single-pipe structure. In the past, the products with double-pipe structure in the domestic market were mainly imported, but now there are also domestic products based on the design of double-pipe structure, and their quality is completely comparable to imported products. The rod-shaped vibrating material level switch is mainly used to measure the granular solid material level. The minimum measurement density of the material that can be measured for the single-tube structure product is only 0.5g/cm³, and the double-tube structure product can be as low as 0.02g/cm³. The latter can Meet most of the on-site measurement requirements of granular material level. The vibrating rod level switch is especially suitable for various granular or powder materials, such as: PVC, sodium hydroxide, lime, cement, sand, soil, coal, dust, flour, sugar, salt, grain, beans, etc. Mainly used in chemical, environmental protection, cement.

Tuning fork level switch application

1. Slurry, viscous, foamy or corrosive liquid.

1. Free-flowing, medium-density solid powder or granules. For example, fly ash, cement, sand, stone powder, plastic particles, salt, sugar, etc.

2. Liquids with explosive and non-explosive hazards, corrosive liquids (acids, alkalis) and high-viscosity liquids. Such as water, acid, alkali, mud, pulp, dyes, oils, milk, alcohol, beverages, etc.

3. Toxic substances

Tuning fork level switch installation attentions

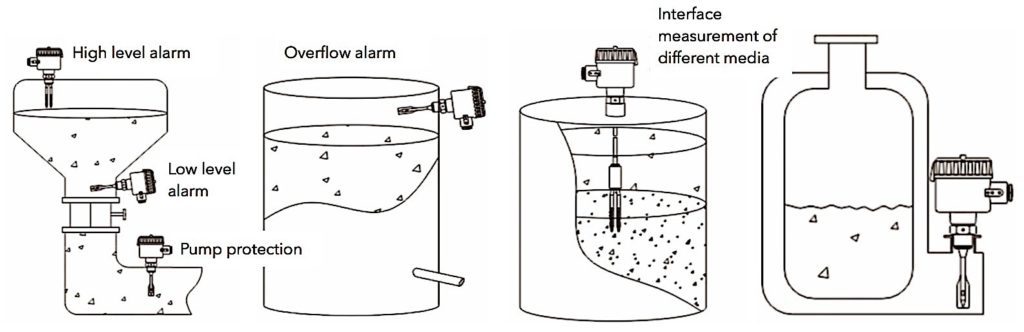

◆ High and low level alarm

This product is an ideal choice for the detection of the highest and lowest level of various liquid tanks. Robust equipment can operate continuously at temperatures up to 302 ° f (150 ° C) and operating pressures up to 1450 psig (100barg), making it particularly suitable for high or low level alarms. It is customary to install an independent high level alarm switch to provide additional backup switches in case of failure.

◆ Prevent overflow

Overflow caused by overfilling will cause harm to human body and environment, resulting in production loss and increasing cleaning cost. The device is a limit switch used to provide overflow signal at any time.

◆ Leakage detection

Flange, gasket, seal and corrosive liquid may leak under adverse conditions.

Most users’ field tanks and containers are installed on the bottom plate or in the protective body to prevent liquid leakage The product can detect any leakage quickly and accurately, so the cost can be significantly reduced.

◆ Hygienic application

As the surface finish (RA) provided by the highly polished tuning fork is better than 0.8um, the product complies with the requirements of strict requirements for basic design criteria for diet and pharmaceutical applications. Made of stainless steel, the product is durable enough to withstand routine steam cleaning at temperatures up to 302 ° f (150 ° C) (CIP cleaning in place).

※Note: As one of the earlier level sensor measurement manufacturer, SenTec provide A wide variety Level switch Sensor for tank level measurement solutions.

For specific vibration fork Level switch Sensor price, please contact our sales engineer.