Sensor to measure High Viscosity Fluid

What Sensor to measure High Viscosity Fluid? High viscosity fluids such as asphalt/ bitumen, Fructose, molasses, honey, glucose, resin etc. are thick making them hard to pour. From this page you will get a total solutions for the high viscosity fluid flow, level, pressure and temperature measurement.

Table of Contents

Backgroud: Sensor to measure High Viscosity Fluid

High viscosity fluids such as asphalt/ bitumen, Fructose,molasses, honey, glucose, resin etc. are thick making them hard to pour and demanding additional power to pump, Low viscosity medium like pure water or milk are very thin and easily pumped. Measuring fluids flow rate with viscosities over 100 mpa.s demand consideration by those charged with designing, operating and maintaining the equipment.

SenTec are always focusing on solutions for the high viscosity measurement according to the different high viscosity fluids features.

Asphalt flow measurement is always a technical problem because of the high viscosity and poor fluidity. The operation temperature of the pipeline liquid asphalt is usually around 200 ° C(392℉). Although the bitumen temperature is very high, the viscosity is still large, and the medium contains a small amount of solid particulate impurities. Conventional liquid flow meters are difficult to meet their bitumen flow measurement requirements. However in-line Coriolis flow meter is a perfect choice for the asphalt /bitumen flow measurement.

Resin can be an organic solvent extracted from petroleum, is cheaper than frankincense and is also used as a perfume. It is more viscous and easy to dry. New colors and ordinary pastel pigments are commonly used for color matching, but high-grade pastels are not suitable. It is also possible to add kerosene and mix it by heating to become a tender oil for use in painting. This resin oil is a common name for white alcohol, mainly aliphatic hydrocarbons, and is also used to dilute paints and is extremely flammable.

it is a kind of high viscous medium , and we often use positive displacement flow meter ( oval gear flow meter ) or coriolis mass flow meter to measure resin flow rate.

High viscosity fluid flow meter

When a flowmeter application involves the use of high viscosity liquid, the customer should pay attention to select an appropriate meter. Lots of different type flow meters cannot measure high viscosity fluid.

1). High viscosity flow meter coriolis meter

Advantage for Coriolis Meter for high Viscosity Fluid

Currently the max flow viscosity we measure by Coriolis meter is 500,000 cp.

Our Coriolis meter now has many successful applications when measuring bitumen, molasses, Heavy crude oil flow rate and so on.

Direct mass flow and density, temperature measurements by only one sensor.

*Advantages of coriolis meter for high viscosity flow meter

Can detect low flow rate.

Has high accuracy measurement value.

Not demand flow conditioning, not straight pipelines request when installation.

*Disadvantage for Coriolis mass flow meter

It is vibration sensitive.

Cannot be used to measure strong corrosive medium

High Price cost

Cannot measure low density gas flow rate.

Pressure drop that rise sharply with viscosity

2). Oval Gear Meter For High Viscosity Liquids Measurement

Advantage of Oval gear flow meter for high viscosity fluid

It is designed primarily for use with higher-viscosity fluids, for flow metering of oils, petrol, diesel, syrups and fuels.

*Advantages of Oval Gear Meter for high viscosity flow meter

High accuracy results over a wide range of viscosities and can measure fluids with viscosity max 2,000 cp.

Low pressure drop

It can work without external power, just mechanical register to display instant flow and total flow , now currently Silver Automation Instruments develops gear flow meter with transmitters which has pulse or 4-20mA,HART,RS485 communication.

Lower Price cost with carbon steel material than Coriolis flow meter price

Simple to install, no straight pipeline needed, and the meter can be mounted in restricted areas.

*Disadvantages of Oval Gear Meter for high viscosity flow meter

Poor choice for medium for water, because the carbon steel wet material can rusty, also an increase in fluid slippage.

The flow meter is really bully and heavy, increase a lot shipping charges when delivery

Relatively high price cost for large gear flow meter sizes for stainless steel material.

Not good for the multi-phase fluids flow measurement such as used as Refrigerant flow meter.

More moving parts needs maintenance compared ,it can be destroyed by flow surges and gas slugs

3). Target flowmeter For High Viscosity Liquids Measurement

The target flowmeter has been used in industrial flow measurement since the 1960s. It is mainly used to measure the flow of high viscosity and low Reynolds number fluids. It has gone through two development stages of pneumatic and electric meters. On the basis of the measurement principle of the original strain gauge (capacitive) target flowmeter, the type flowmeter adopts the latest force induction sensor as the measurement and sensitive transmission element, and uses modern digital intelligent processing technology. A new type of flow meter.

* Advantages of target flowmeter

·Suitable for various pipe diameters: from Φ6~Φ2000mm to larger

·Suitable for high and low temperature medium: from -196℃~+450℃

·Suitable for high pressure conditions: from 0 to 42Mpa (gauge pressure)

High Viscosity Fluid Pressure Sensor

The fluid pressure sensor is a device that can feel the pressure signal and converts the pressure signal to the available output signal in accordance with a certain rule. The fluid pressure sensors are usually composed of pressure sensitive elements and signal processing units. According to the different types of pressure test, the fluid pressure sensor can be divided into table pressure sensors, differential pressure sensors and absolute pressure sensors.

A high-precision viscous flow pressure sensor is especially suitable for pressure measurement of viscous fluids.

High-viscosity fluid pressure sensors all have pressure chambers, which require a capillary to introduce the measured medium into the pressure chamber for pressure measurement. Therefore, when these sensors measure the pressure of high-viscosity or particle-containing viscous media, they are prone to blockage, resulting in inaccurate measurement. or cannot be measured.

Subscribe To get new products and solutions

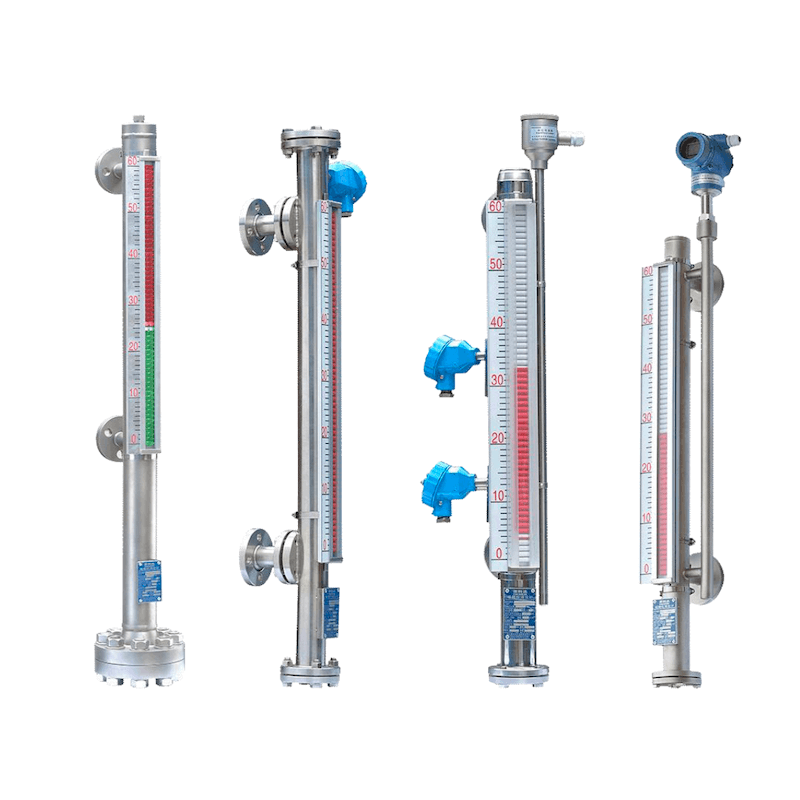

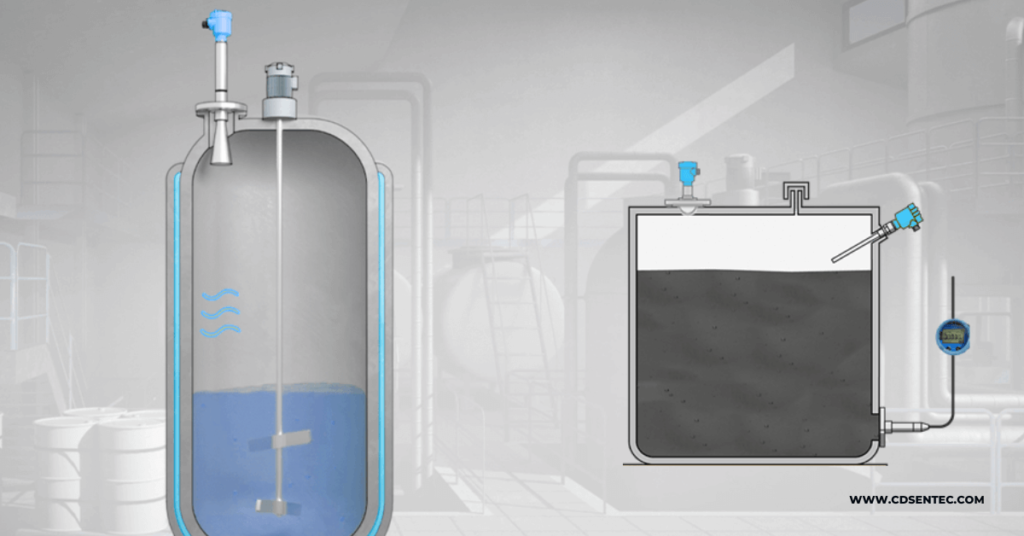

High Viscosity Fluid level Sensor

Viscosity as well as highly viscous (thick) liquids (eg oils, paints, molasses) present unique measurement challenges.

Viscosity is used to describe the thickness of a substance and defines its ability to change shape under stress or tension. To give you a better understanding of the different viscosity levels or centipoise (cP) measurements, water is 0.894 cP, castor oil is 650cP, and ketchup is 50,000 – 100,000 cP. As you can see, “thickness” plays an important role in how these different fluids flow freely. When trying to get accurate measurements, you can’t use the same gauge or level in every situation. Problems including a stuck float or even damage to the pressure port are possible. Keep in mind that temperature conditions may alter viscosity levels, so be sure to choose the solution that is more compatible with your specific application.

A better choice for viscous liquids is to choose a non-contact option, such as an optical or ultrasonic level sensor, to measure the level accurately. Here’s why: The measurement of sound waves and echoes emitted by ultrasonic level sensors makes it possible to know the level without physically touching the substance – eliminating the aforementioned risks. Use an optical magnetic flap level gauge to measure using a laser wave or forward light scattering and a probe. There are no moving parts, and this option works well because it measures the presence or absence of many different types of liquids.

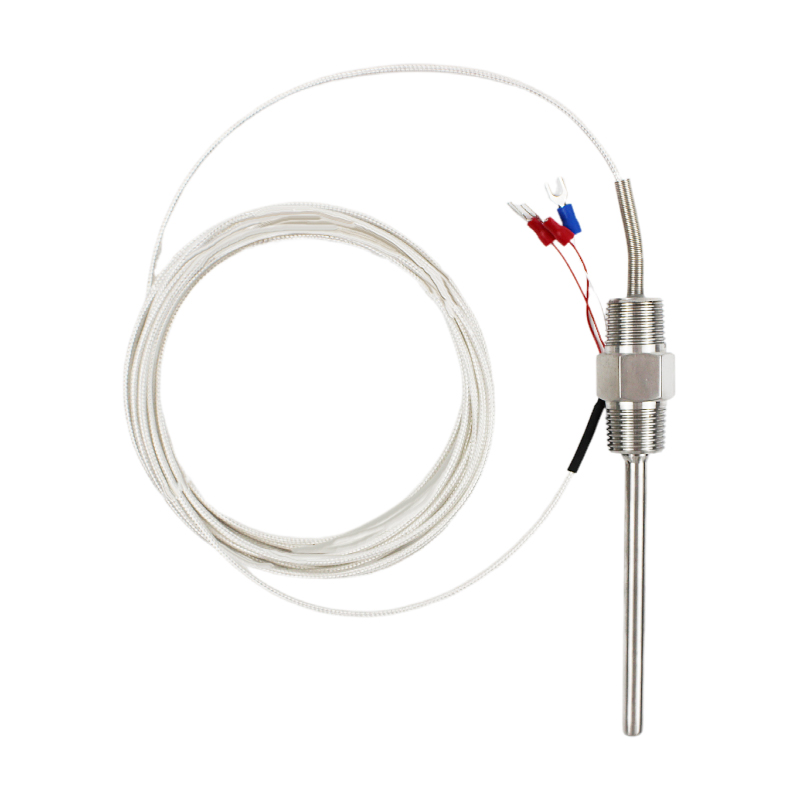

High Viscosity Fluid temperature Sensor

A temperature transducer is a sensor that senses temperature and converts it into a usable output signal. The temperature sensor is the core part of the temperature measuring instrument, and there are many varieties. According to the measurement method, it can be divided into two categories: contact type and non-contact type. According to the characteristics of sensor materials and electronic components, it can be divided into two categories: thermal resistance and thermocouple.

The sensor used to measure the high viscosity fluid called high viscosity fluid temperature sensor.

Subscribe To get new products and solutions

Latest Posts

Unveiling The Potential: The Role of Smart Sensors in Creating the Ultimate Smart City

In the age of digital innovation, the concept of the smart city is no longer a distant dream but a reality. A smart city is

Unveiling the Future: How Industry 4.0 and Smart Sensors are Revolutionizing the Industrial Landscape

Introduction to Industry 4.0 Welcome to a new era in industrial production, commonly referred to as Industry 4.0. This term describes the ongoing automation of

Smooth Sailing: How Shipborne Meteorological Instruments Enhance Offshore Weather Monitoring

Shipborne meteorological instruments play a crucial role in enhancing offshore weather monitoring. These instruments are specifically designed to provide accurate and real-time weather data, ensuring

Maximizing Efficiency: An In-depth Exploration of Reactor Vessel Instrumentation Systems

The reactor vessel level instrumentation system is a critical component of nuclear and chemical power plants. It is designed to monitor and manage the water