- Tel: +86 28 87436908

- Email: info@cdsentec.com

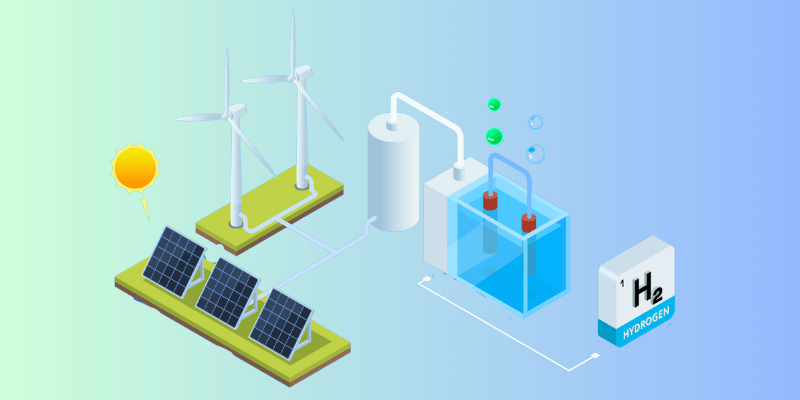

Green hydrogen production processes require instrumentation and online analyzers for accurate monitoring and control. Sensors, analyzers, and transmitters are used to measure conductivity, temperature, level, pressure, and flow in hydrogen electrolysis production processes

A PEM (Proton Exchange Membrane) electrolyzer is a type of electrolyzer that uses a solid polymer electrolyte membrane to facilitate the electrolysis process. It is commonly used for the production of hydrogen gas (H2) from water (H2O).

Using a pressure transmitter, the pressure in the water inlet pipe on the oxygen side and the exhaust pipe on the hydrogen side can be monitored.

SenTec relative, differential and absolute pressure field instrument design with stainless steel cell with EX certified and gold coating option, membrane options to protect against hydrogen diffusion

SenTec offs 5 different flow measurement technologies, electromagnetic, Coriolis, ultrasonic, vertex, and differential pressure for water demineralization plant and hydrogen applications. Clamp-on ultrasonic flow meter with non-invasive measurement against H2 diffusion and embrittlement.

Intrinsically safe, flameproof design temperaature transmitter, sensors and clamp-on temperature measurement solutions for vessels and pipe from simple applications to sophisticated solutions. Clamp-on solutions to reduce potential hydrogen leakage.

In electrolysers, water (H2O) is decomposed into hydrogen (H) and oxygen (O) with the help of electricity generated from renewable energy sources. Green hydrogen is produced from this and does not emit CO2 during its production. In the PEM electrolyzer, a proton exchange membrane is used and ultrapure water is injected. The protons pass through the proton membrane under the action of voltage, hydrogen is released from the cathode, and oxygen is released from the anode. On the oxygen side, a liquid level gauge is used to control the amount of ultrapure water; on the hydrogen side, a liquid level gauge is used to monitor excess water volume.

PEM electrolyzer field smart instrumentation are used to gather data on various parameters such as temperature, pressure, flow rate, voltage, and current during the electrolysis process. They provide valuable information for optimizing the performance and efficiency of the electrolyzer, ensuring safe operation, and troubleshooting any issues that may arise.

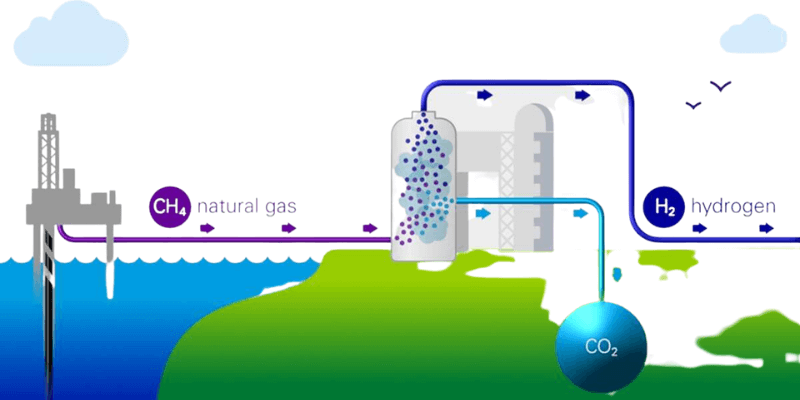

Green hydrogen storage and transportation are essential components of a sustainable hydrogen infrastructure. Currently, hydrogen is transported from production sites to end-use locations through various methods.

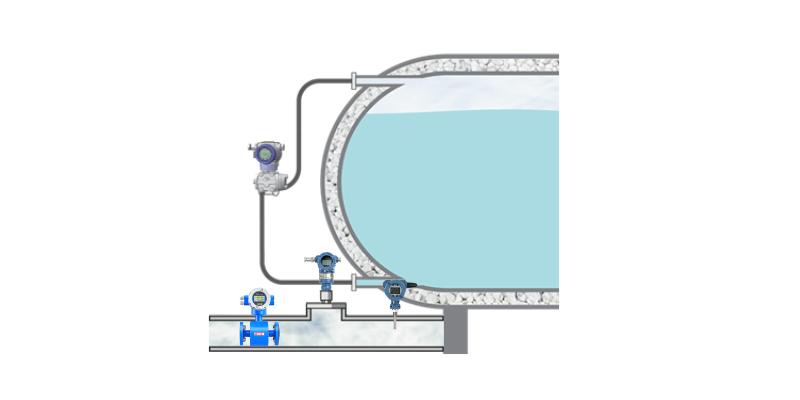

Hydrogen storage tanks can store different capacities of hydrogen depending on their size, and can be used in hydrogen refueling stations or hydrogen transportation. To store as much hydrogen as possible, the tanks are pressurized up to 1,000 bar. But at room temperature, hydrogen is always in the gaseous state. Using a pressure transmitter, the pressure can be measured and controlled accordingly.

When storing hydrogen, it must be cooled to -253°C at 1 bar to keep it in the liquid state in order to minimize losses. Liquid hydrogen is generally stored in insulated double-layer tanks filled with gaseous hydrogen above the liquid level. As soon as liquid hydrogen leaves the insulated container, it vaporizes and heats up to ambient temperature, so that level and flow can be reliably measured by means of the widely used differential pressure principle.

In the hydrogen industry, hydrogen pipelines are used to transport hydrogen from the point of production to storage and later to the point of demand. Reliable pressure monitoring is essential during this process.

Green hydrogen storage and transportation instrumentation refers to the devices and systems used to monitor and control the storage and transportation processes of green hydrogen. These instruments play a vital role in ensuring the safety, efficiency, and reliability of the storage and transportation infrastructure.

Green hydrogen storage and transportation are essential components of a sustainable hydrogen infrastructure. Currently, hydrogen is transported from production sites to end-use locations through various methods.

Green hydrogen extractive process gas monitoring is an essential component of ensuring the quality and purity of green hydrogen production. The process involves the analysis and measurement of various gases and impurities to ensure the efficiency and effectiveness of the electrolysis process. By monitoring the gas composition in real-time, any deviations or impurities can be detected and addressed promptly, leading to the production of high-quality green hydrogen. Whether it is used for hydrogen, or for ammonia, methane and synthetic fuels converted from hydrogen, SenTec measuring instruments can ensure accurate measurement of the amount of materials in each process, whether in large batches or small doses.

A hydrogen process gas flow meter is a tool used in green hydrogen production to monitor and measure the flow rate of hydrogen gas in various processes. While specific information about a green hydrogen extractive process gas flow meter is not available, the importance of monitoring gas flow in green hydrogen production cannot be understated. Accurate flow measurement is crucial for optimizing production efficiency, ensuring safety, and maintaining the quality of the hydrogen gas. Different flow meter technologies, such as turbine flow meters, ultrasonic flow meters, and thermal mass flow meters, can be used for this purpose.

A green hydrogen process online analyzer offers several key features for real-time monitoring and gas analysis in green hydrogen production. They plays a crucial role in ensuring the quality, efficiency, and control of green hydrogen production through real-time monitoring and accurate gas analysis.

SenTec online resource library is a place you can know more knowledge from video, cases study, e-book etc.