Process instrumentation in mining and metallurgy industries

Process instrumentation plays a crucial role in the mining and metallurgy industries. It involves the use of various instruments and devices to monitor, control, and optimize the processes involved in mining and metallurgical operations.

Mining and metallurgy requirements

The mining and metallurgy industries have specific requirements when it comes to process instrumentation. These requirements are crucial for ensuring the safe and efficient operation of mining and metallurgical processes, as well as the production of high-quality products.

Explosion-proof

ATEX certificated process measuring instrumentation from SenTec deliver reliable data on the volume, level and pressure of all types of media.

Innovation solutions

Innovation solutions in the mining and metallurgy industry can play a significant role in mitigating environmental impact and promoting sustainable practices.

Internet of things technology

By leveraging IoT, mining and metallurgy industry can overcome various challenges and optimize IoT communication data gathering.

Process instrumentation in mining and metallurgy industries

In the mining and metallurgy industries, various types of process instrumentation are commonly used for control and monitoring purposes. Some of the frequently utilized instruments include point level instrumentation, continuous level instrumentation, and non-contact instruments, pressure instruments etc. These instruments play a crucial role in ensuring accurate and reliable measurements, optimizing processes.

- All

- Pressure

- Level

- Temperature

- Flow

- density

Production process application examples

Process instrumentation in the mining and metallurgy industries plays a crucial role in ensuring accurate measurements, process optimization, and dust mitigation. The requirements for process instrumentation in these industries include accuracy, reliability, safety, real-time monitoring, compatibility, calibration, and data logging.

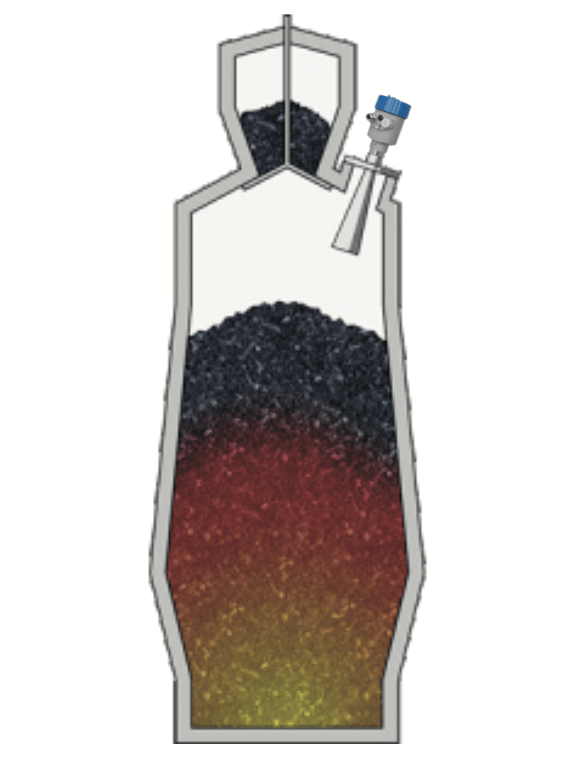

Blast furnace material level measurement

During smelting, iron ore, flux, coke and other furnace materials need to be transported from the silo to the top of the blast furnace, and loaded by conveyor belt or skip car. In order to ensure reasonable distribution of the ore layer and coke layer, the SRL series radar level transmitter is needed for material level measurement.

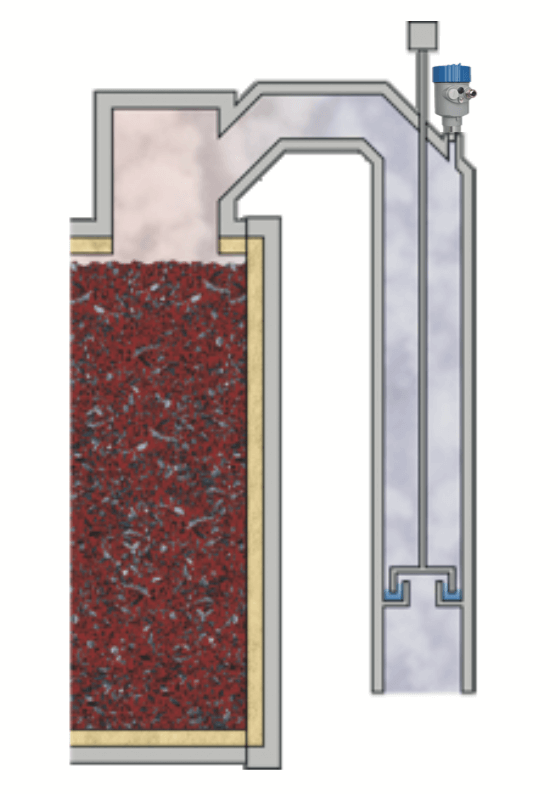

Coke oven pressure measurement

Coke provides the necessary heat for production in the process and acts as a reducing agent and support structure in the blast furnace. During coking, in order to achieve the best production conditions, the coking plant will individually adjust the pressure of each coke oven. PMD3051 is an ideal instrument for measuring pressure.

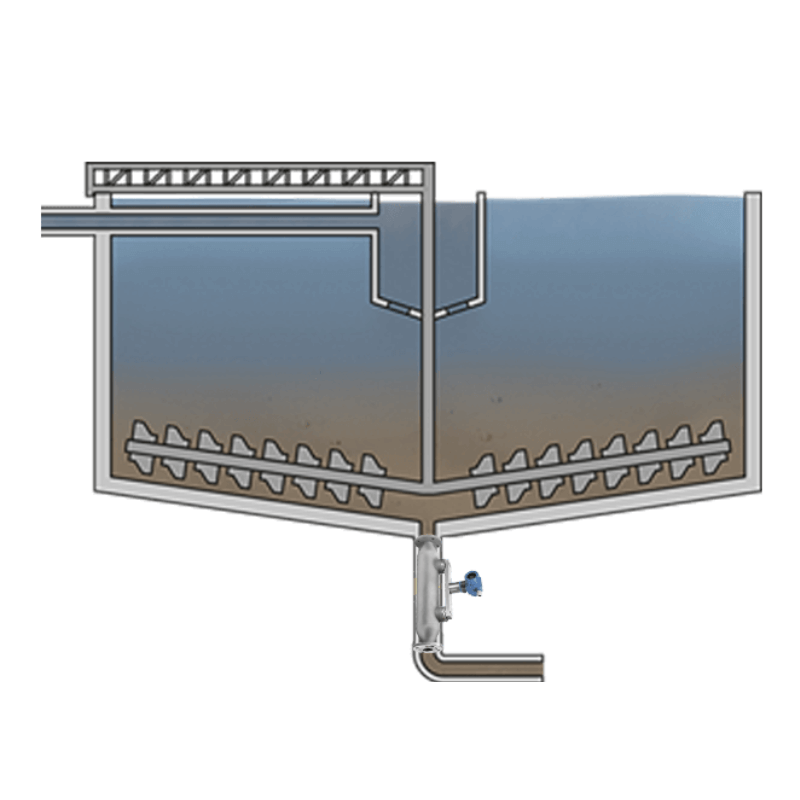

Density measurement of pulp thickener

The slurry obtained from mining will enter the concentrator through the feed barrel, and the solids in the slurry will settle to the bottom of the tank. To effectively control the operation of the concentrator, accurate density measurement is required at the underflow port. The SENTEC SPX series density meter provides accurate online measurement.

Warehousing and transportation

The warehousing and transportation process in mining and metallurgy industries also benefit from process instrumentation. Instrumentation plays a crucial role in ensuring accurate measurements of various parameters such as temperature, pressure, and level in storage tanks and transportation vessels.

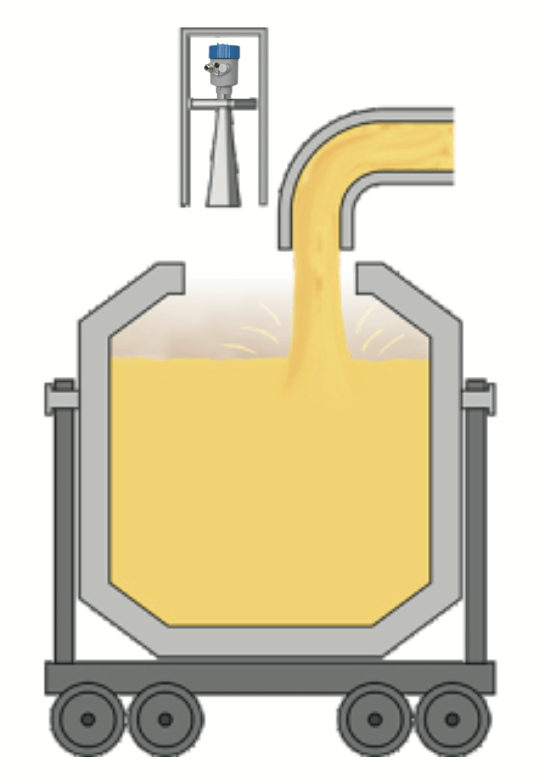

Torpedo tanker liquid level measurement

After tapping from the blast furnace, the molten iron flows into torpedo cars at temperatures exceeding 1400°C and is transported to foundries or converters for further processing. SRL630 radar non-contact liquid level measurement is crucial for the safe feeding of torpedo tankers.

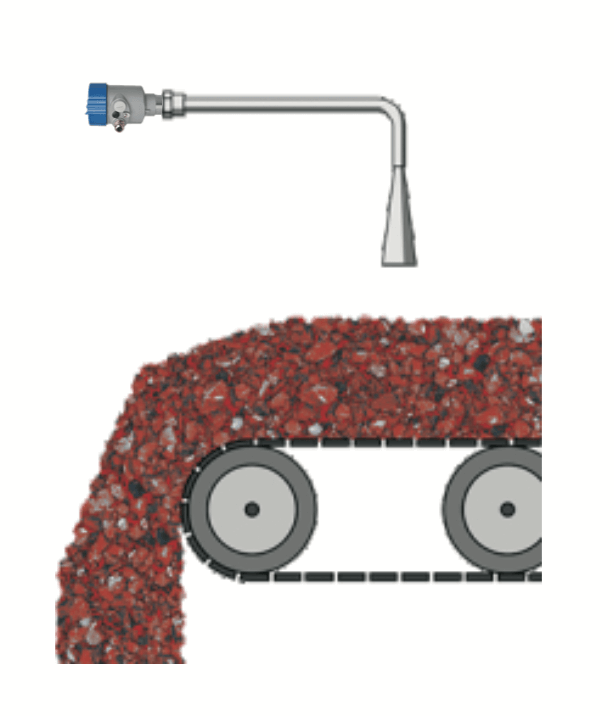

Level measurement in the sintering process

After the sintering is completed, the material is sent to the cooling equipment to cool down to about 150°C. When conveying materials, in order to ensure cooling efficiency, SRL600 radar level transmitters used for material layer thickness measurement on the conveyor belt.

Level measurement and limit measurement in auxiliary tanks

IOT solutions

With its clever networking design and unique services, SenTec process instruments greatly improve the efficiency and security of the entire value creation chain.

Getting started to be Partner with us

Get a Quote

Request a quote from us based on your specific requirements

To be a Distributor

If you want to distribute sentec brand in your local area, you can contact us for more.

Installation & Maintain

A group of professional engineer is here to help your sensor installation & maintenance.