The mining industry, a cradle of human civilization, has evolved with the progression of technology and science. It has been an essential part of economic development, contributing significantly to the GDP of many countries. The mining industry is responsible for extracting valuable minerals and other geological materials from the earth, which are used in a variety of sectors, including construction, manufacturing, and energy generation.

However, the mining industry is not without its challenges. It faces issues related to environmental sustainability, worker safety, and efficiency. These challenges necessitate the integration of advanced technology and innovative methodologies to improve operations. With the advent of the digital era, the mining industry is undergoing a significant transformation, reshaping its traditional practices.

In this context, measurement techniques play a pivotal role in enhancing the efficiency and safety of mining operations. The following sections will delve deeper into the role of measurement, traditional techniques, and the innovative methods revolutionizing the mining industry.

The Role of Measurement and Control Instruments in Mining

Measurement and control instruments are indispensable in the mining industry. They ensure the accurate extraction of minerals, maintain the safety of the workforce, and enhance operational efficiency. The role of these instruments is particularly vital in monitoring and controlling various parameters such as temperature, pressure, humidity, and gas concentrations in mining operations.

Traditional measurement techniques in the mining industry involved manual labor with a high risk of errors and safety concerns. However, with advancements in technology, this scenario has changed drastically. Control and monitoring equipment have introduced automation, reducing human intervention and consequently, the associated risks.

Traditional Measurement Techniques in the Mining Industry

Traditional measurement techniques in the mining industry were heavily reliant on manual processes, involving significant labor and time. These methods mainly included manual surveying for mineral exploration, using simple tools like compasses, clinometers, and tape measures. While these methods served their purpose in the past, they were fraught with challenges such as inaccuracy, inefficiency, and risk to worker safety.

Moreover, the monitoring of environmental parameters such as gas concentration, temperature, and humidity in mines was also done manually. Miners used canaries as a warning system for toxic gases, a practice fraught with obvious shortcomings.

Advanced Measurement Methods in Mining: An Overview

The advent of technology brought about a paradigm shift in the mining industry, introducing Advanced Measurement Methods in Mining. These methods leverage cutting-edge technology like drones, LiDAR (Light Detection and Ranging), and advanced Geographical Information Systems (GIS) for mineral exploration and mine mapping.

Moreover, advanced sensors and monitoring systems are being employed for environmental monitoring in mines. These systems provide real-time data on various parameters, enabling quick response in case of hazardous situations, thereby ensuring the safety of miners.

The Importance of Mining Engineering

Mining engineering plays a crucial role in the mining industry, bridging the gap between the extraction of minerals and their subsequent use in various industries. It involves the application of advanced scientific and technological methods to the extraction of minerals from the earth.

Mining engineering encompasses various aspects of mining, including mineral exploration, feasibility studies, mine design, production planning, and environmental management. It is integral to the successful implementation of innovative measurement techniques in the mining industry.

Innovative Measurement Techniques in the Mining Industry

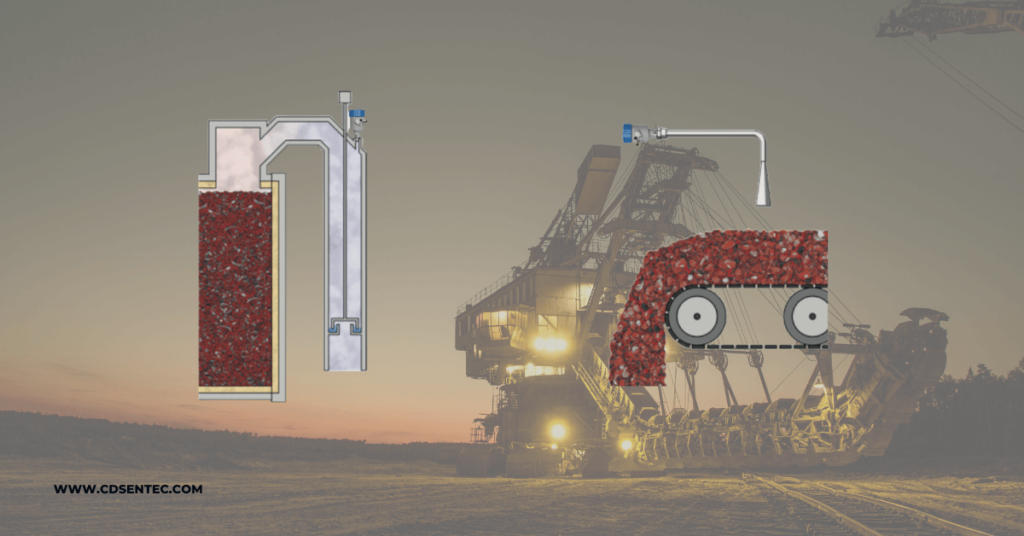

In recent years, several innovative measurement techniques have revolutionized the mining industry. These include 3D laser scanning, hyperspectral imaging, and automated monitoring systems.

3D laser scanning allows for accurate and detailed mapping of mines, contributing to better planning and safer operations. Hyperspectral imaging, on the other hand, enhances mineral exploration by providing detailed spectral information about the composition of geological materials.

The Rising Role of Mining Automated Monitoring Systems

Mining Automated Monitoring Systems have brought about a significant transformation in the mining industry. These systems, equipped with advanced sensors and data analytics capabilities, provide real-time monitoring of various parameters, reducing the risk of accidents and enhancing operational efficiency.

These systems enable remote monitoring of mining operations, reducing the need for manual inspections and thus, mitigating the associated risks. Moreover, the data generated by these systems provide valuable insights for decision-making, contributing to the overall efficiency of mining operations.

How Control and Monitoring Equipment are Revolutionizing the Mining Industry

Control and monitoring equipment have brought about a sea change in the mining industry. These equipment, integrated with advanced technology like AI and IoT, provide real-time data on various parameters, allowing for quick response to any anomalies and ensuring the safety of miners.

Furthermore, these equipment enable automation of various mining processes, reducing the need for manual labor and thereby enhancing efficiency. The data generated by these equipment is also instrumental in predictive maintenance, leading to reduced downtime and increased productivity.

Case Studies of Successful Implementation of Innovative Mining Measurement Techniques

Several case studies highlight the successful implementation of innovative mining measurement techniques. For instance, Rio Tinto, a leading global mining group, has implemented automated drilling systems in its Pilbara iron ore mines in Australia. These systems use advanced sensing technology to drill holes with high precision, enhancing efficiency and safety.

Similarly, BHP, another global mining giant, has implemented remote operations centers for its mining operations. These centers use advanced monitoring and control systems to manage operations remotely, reducing the need for on-site personnel and thus, enhancing safety and efficiency.

The Future of the Mining Industry: More Advanced, Accurate, and Efficient

Looking ahead, the future of the mining industry appears to be more advanced, accurate, and efficient, thanks to the ongoing technological advancements. Artificial Intelligence (AI), Machine Learning (ML), and Internet of Things (IoT) are expected to play a significant role in this transformation.

These technologies, coupled with innovative measurement techniques, are set to revolutionize the mining industry, enhancing safety, efficiency, and sustainability. Moreover, the integration of these technologies with mining engineering practices will further accelerate the transformation, making the mining industry more resilient and future-ready.

Conclusion

In conclusion, innovative measurement techniques are revolutionizing the mining industry, making it safer, more efficient, and sustainable. The integration of advanced technology with traditional mining practices is paving the way for a new era in the mining industry. While challenges remain, the future looks promising, with technology and innovation at the forefront of this transformation.