Sensor to measure corrosive acids

What sensor to measure corrosive acids? The use of harmful and corrosive acids in industry dates back hundreds of years. How to measure strong hot corrosive acids like sulfuric acid (H2SO4), sour gas (H2S) and hydrochloric acid (HCl) ?

Table of Contents

Backgroud: sensor to measure corrosive acids

The use of harmful and corrosive acids in industry dates back hundreds of years. Unlike the days of old, current industries are more focused on the safety of the workers and the quality of the products which is why the corrosive acids are kept separate from the rest of the machinery and are monitored.

Acid resistant flow meters

Regardless of what the acid is used for, too much or too little acid flowing through the pipes is a bad thing. Industries and plants need to ensure the proper amount of acid is being used at all times and there is no back up on the flow. The motioning of acid flow is the main reason why plants and companies will invest in a flow meter. We are often requested by sulfuric acid flow meter.

Flow meters recommended for use with acids or chemically aggressive liquids. SenTec supplies acid resistant flow meters to measure the flow of strong hot corrosive acids like sulfuric acid (H2SO4), sour gas (H2S) and hydrochloric acid (HCl). The combination of PTFE or PFA liner with Pt/Iridium Alloy electrodes magnetic flow meter solves this problem and creates the most corrosion resistant flow meters available to industry.

Besides we can also supply metal tube rotameter with PTFE material which can also measure corrosive acid fluids.

Chemical Flow Meter

Chemical flow meters are common in industries like petrochemical plants and refineries. In such industries, they play a vital role in the manufacturing process since they help to enhance manufacture efficiency.

1). Aggressive chemical measurement-Variable area rotameter/ magnetic flow meter

Chemical industries use magnetic flow meters to facilitate the aggressive measurement of chemicals. You can use magnetic flow meters to measure corrosive chemicals like hydrochloric acid, sulphuric acid, caustic soda, and brine. However, only magnetic flowmeters that have suitable electrodes and liners are efficient in measuring such corrosive liquids. Additionally, you can also measure the aggressive chemicals/fluids using digital rotameters that are lined with PTFE (Teflon),magnetic flow meter is a kind of digtial chemical flow meter with 4-20mA analog outputs and pulse output, it also has digital display to show flow total flow and instant flow.

2).Low corrosive, low viscous and clean liquid measurement -Turbine flow meters (TUF)

These are flow meters that measure liquids that are clean, less viscous, and less corrosive. Such fluids include solvents, solutions, ethanol, diesel, and clean water. Turbine flow meters are less expensive and usually have chemical flow sensors that have a compact design. These flow meters are volumetric, meaning that they can measure liquids passing through them either indirectly or directly. Some of the advantages of using turbine flow meters are that they have high accuracy, can measure high pressure, and have a large measuring range.

3). Low flow rate chemical flow meter -Rotameter or micro type oval gear flow meter

A rotameter measures the flow rate of a gas or a liquid. It comprises a measuring scale, float, and a tube. A low flow rate rotameter detects a minimum/low flow rate in a liquid/gas. In this category of rotameters, we supply a rotameter known as the metal tube. The tube in the metal tube is usually tapered and has indicators. The function of the indicator is to display the measuring results after measuring. These tubes also have pulse output/4-20Ma transmitters, which facilitates control. Rotameters are cost-effective since they are easy to construct. Therefore, using them helps to save costs. They also have a small design hence portable.

Micro oval Gear flow meter can detect ultra mini chemical flow, It is a kind of positive displacement flow meter for precise volume flow measurement of mini or low chemical flow liquid, the liquid include chemical, sealant, toluene, glue, detergents, gelectrolyte, ethylene, additive,etc,low flow chemical flow meter.

4).High viscosity chemical flow meters-Coriolis flow meter & oval gear flow meter

Both the oval gear flow meter and the Coriolis flowmeter measure fluids that have high viscosity. Such fluids include glue, resin, asphalt, and molasses. Oval gear flow meters have two oval gears which they use to trap the fluids. On the other hand, a Coriolis flowmeter has a tube and a vibrator for fluids measurement purposes. The flow sensors present in these two flow meters have a rugged design and are bulky too. The flow meters have different protocols and outputs, which helps to control processes in the factory facility.

Subscribe To get new products and solutions

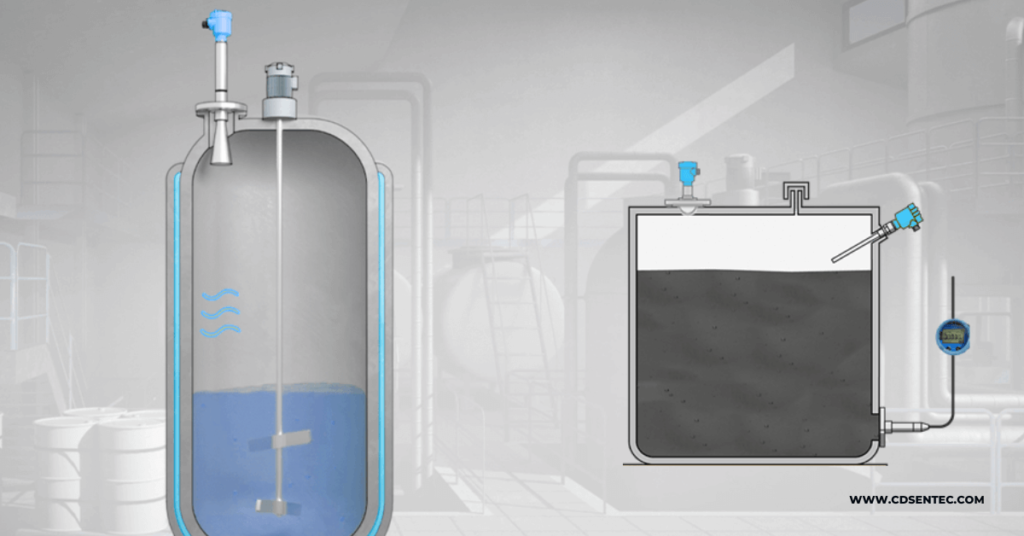

Acid Resistant Level transmitter

Most conventional liquid sensors require being in contact with liquids or fluids that are measured to establish reading or measurements. Such liquids like water may not pose a challenge when it comes to immersion. However, delicate materials such as wastewater, acids, manufacturing slurries, and gasoline may pose a considerable threat. They may cause corrosion of the submersible float instantly or with time, making it challenging to register measurements. In such circumstances, non-contact liquid level sensors get highly regarded.

Among the plethora of liquid sensors out there, we are going to narrow it down to two types; Ultrasonic level sensors and Radar level sensors and their features.

*Features of Non-contact ultrasonic Liquid Level Sensors

For starters, ultrasonic flow meters can measure liquids in a various pipe sizes ranging from medium to large pipes. The size of the pipes doesn’t affect its accuracy.

Apart from measuring liquids, it comes across as an effective medium in measuring gases and non-conductive liquids.

Requires less to no calibration at all

The sensors have no movable parts, thus no wear and tear.

*Features of Non Contact Liquid Radar Level sensors

It’s a non-contact form of measurement that can continuously measure liquids over long distances.

Its accuracy is unaffected by media such as dust, uneven surfaces, vacuum, pressure, and turbulence

Non Contact Liquid Radar Level sensors is simple to operate as it is easily mountable and comes with a push-button form of calibration. It mainly comes in two versions, which are single-frequency level sensors for liquid measurement and dual-frequency level sensors for measurements for substances such as sand, asphalt, or other solids.

Acid Resistant pressure sensor

The corrosion-resistant ceramic pressure sensor has no liquid transfer, and the pressure acts directly on the front of the ceramic diaphragm, causing a slight deformation of the diaphragm. The thick film resistor is printed on the back of the ceramic diaphragm and connected to a Wheatstone bridge (closed bridge). Due to the piezoresistive effect of the varistor, the bridge produces a highly linear voltage signal proportional to the pressure and excitation voltage. The standard signal is calibrated to 2.0/3.0/3.3mV/V depending on the pressure range and is compatible with strain gauge sensors. Through laser calibration, the sensor has high temperature stability and time stability, and the sensor comes with temperature compensation of 0~70 °C.

The pressure sensor can choose customized 316L, Hastelloy C, Monel, tantalum and other anti-corrosion wetted materials according to the corrosive characteristics of the medium

Subscribe To get new products and solutions

Acid Resistant liquid density meter

Commonly used liquid density meters and hydrometers include static pressure density meters and vibrating density meters.

Hydrostatic Density Meter

Its working principle is: the static pressure of the liquid column at a certain height is proportional to the density of the liquid, so the density of the liquid can be measured according to the static pressure value measured by the pressure measuring instrument. The bellows (see diaphragm and bellows) is a commonly used pressure measuring element, and the densitometer that directly measures the static pressure of the sample liquid column is called the bellows static pressure densitometer. Another commonly used one is the single-tube blow air density meter. It measures the air pressure instead of directly measuring the liquid column pressure. Insert the air blowing pipe into a certain depth below the liquid surface to be tested, and the compressed air will continuously escape from the bottom of the pipe through the air blowing pipe. At this time, the pressure of the air in the tube is equal to the pressure of the sample liquid column at that height, and the pressure value can be converted into density.

Vibrating Density Meter

Its basic working principle is: when an object is excited and vibrates, its vibration frequency or amplitude is related to the mass of the object itself. If the object is filled with a certain volume of liquid sample, the change of its vibration frequency or amplitude will reflect the mass or density of the certain volume of sample liquid.

When measuring the corrosive acid, the density meter can choose customized 316L, Hastelloy C, Monel, tantalum and other anti-corrosion wetted materials according to the corrosive characteristics of the medium.

Latest Posts

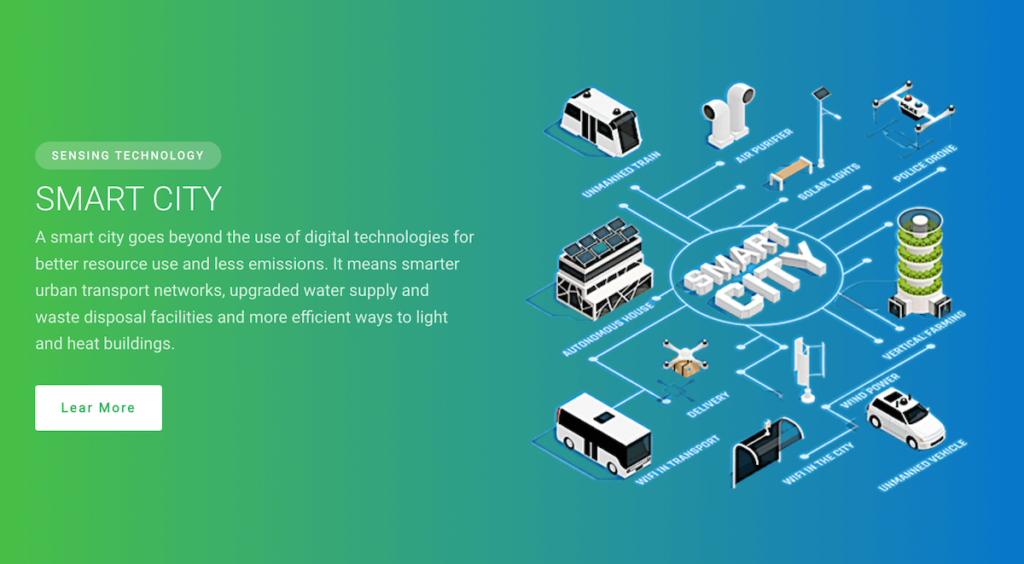

Unveiling The Potential: The Role of Smart Sensors in Creating the Ultimate Smart City

In the age of digital innovation, the concept of the smart city is no longer a distant dream but a reality. A smart city is

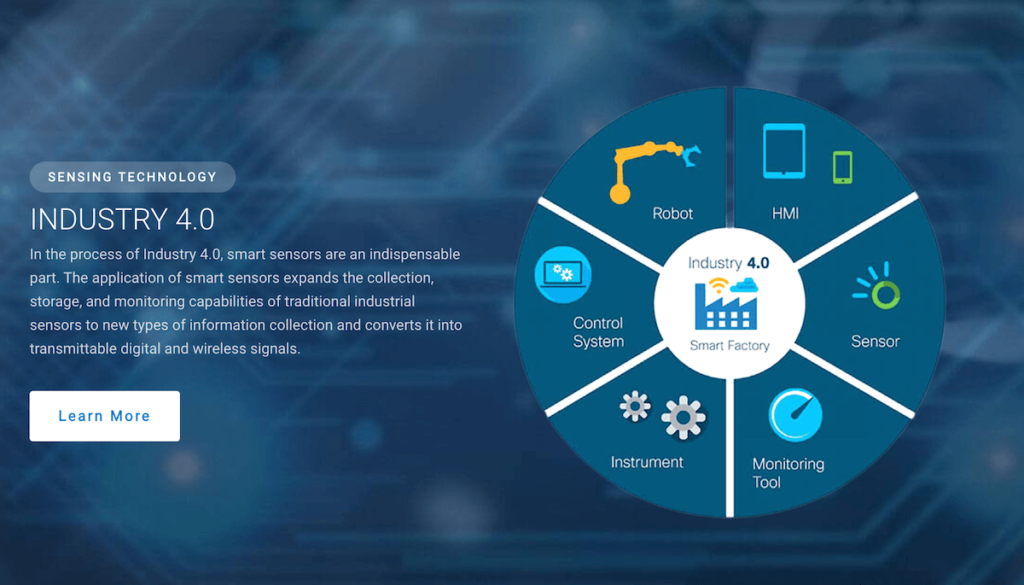

Unveiling the Future: How Industry 4.0 and Smart Sensors are Revolutionizing the Industrial Landscape

Introduction to Industry 4.0 Welcome to a new era in industrial production, commonly referred to as Industry 4.0. This term describes the ongoing automation of

Smooth Sailing: How Shipborne Meteorological Instruments Enhance Offshore Weather Monitoring

Shipborne meteorological instruments play a crucial role in enhancing offshore weather monitoring. These instruments are specifically designed to provide accurate and real-time weather data, ensuring

Maximizing Efficiency: An In-depth Exploration of Reactor Vessel Instrumentation Systems

The reactor vessel level instrumentation system is a critical component of nuclear and chemical power plants. It is designed to monitor and manage the water