Process control instruments for pulp and paper industry

The pulp and paper industry relies on process control instruments to ensure high-quality production and safe plant operation. Instruments such as pH and conductivity sensors, flow, temperature, gas levels play a crucial role in maintaining process quality.These instruments aid in achieving higher consistency control, improved product quality, and cost savings.

Pulp and paper industry requirements

The pulp and paper industry has specific requirements for consistency control, efficiency and cost savings,safety and compliance and real-time monitoring and control when it comes to process control instruments. These instruments are crucial for ensuring high-quality production and safe plant operation.

Sustainable development

Sustainable development is necessary to drive the transition towards optimal pulp and paper and create a greener and more resilient pulp and paper system.

Innovation solutions

Pulp and paper industry is actively seeking innovative solutions to address traditional and emerging threats to paper resources.

Internet of things technology

By leveraging IoT, pulp and paper industry can overcome various challenges and optimize IoT communication data gathering.

Process control instruments for pulp and paper industry

To meet these requirements, SenTec specializes in providing a wide range of measuring instruments and systems tailored to the needs of the pulp and paper industry. These instruments help achieve higher consistency control, improved product quality, and cost savings, while also ensuring safety and compliance with industry standards.

- All

- Pressure

- Level

- Temperature

- Flow

- Density

Application examples

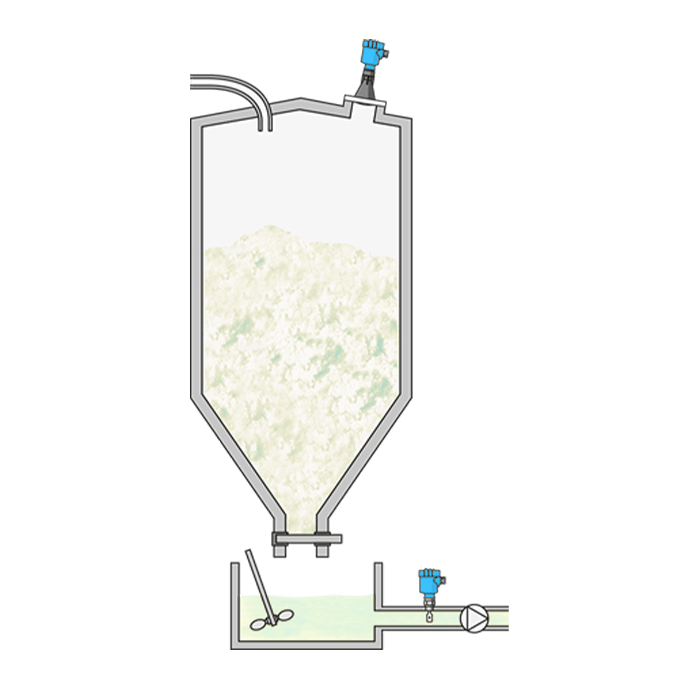

Process control instruments are crucial for maintaining high-quality production and safe plant operation in the pulp and paper industry from wood raw material to finished paper. By accurately measuring and controlling the consistency, the instrumentation and control in paper industry ensures consistent quality throughout the production process.

Wood processing

Pulp and Paper making

Bring innovation for your cases

The paper industry places high demands on the productivity and availability of equipment. SENTEC sensors gives absolutely accurate and reliable measurements solutions for level, limit, pressure, flow and density parameters.

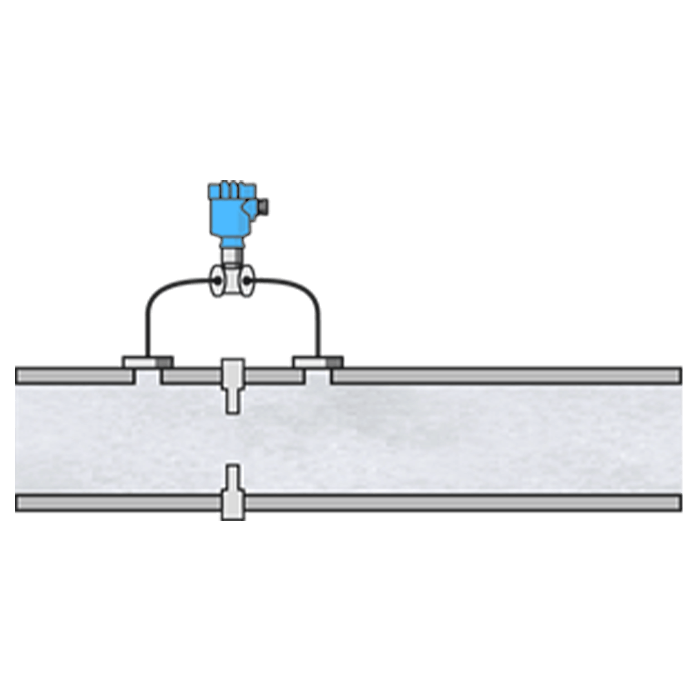

Liquor recovery

SPX504 Density meter for the liquor density measurement in the pipelines with eco-friendly and energy-efficient process control.

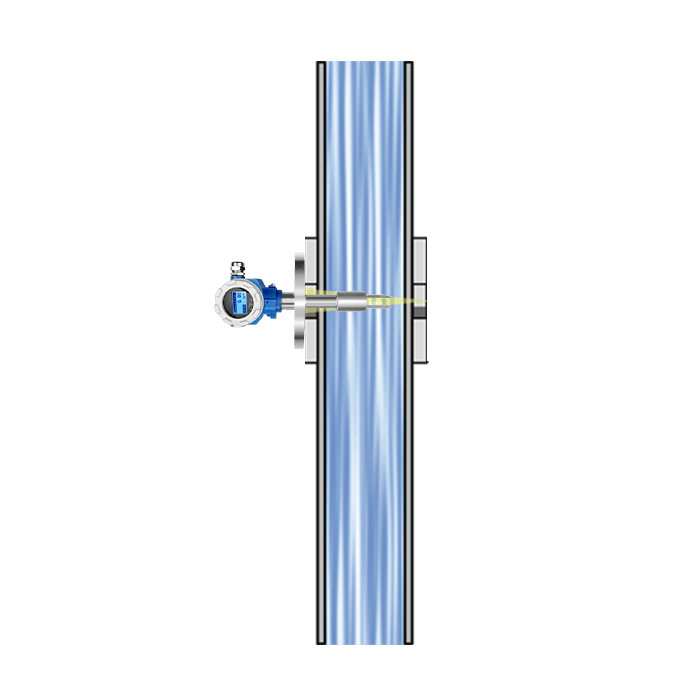

Steam pipes

Measuring flow in water steam pipes using an PMD differential pressure orifice plate flow meter with built-in differential pressure transmitter

IOT solutions

With its clever networking design and unique services, SenTec process instruments greatly improve the efficiency and security of the entire value creation chain.

Getting started to be Partner with us

Get a Quote

Request a quote from us based on your specific requirements

To be a Distributor

If you want to distribute sentec brand in your local area, you can contact us for more.

Installation & Maintain

A group of professional engineer is here to help your sensor installation & maintenance.