Choosing the right liquid level meter is crucial for ensuring accurate measurements in various industrial applications. Among the popular options are ultrasonic and radar liquid level meters. Both technologies offer unique advantages and are suitable for different environments and requirements. This blog post delves into the differences, benefits, and applications of ultrasonic and radar liquid level meters, helping you make an informed decision for your specific needs.

Introduction

Liquid level meters are essential tools in industries such as water treatment, oil and gas, chemical processing, and food and beverage. They help monitor and control the level of liquids in tanks and vessels, ensuring process efficiency and safety. Two common types of liquid level meters are ultrasonic and radar. While both are non-contact measurement technologies, they operate on different principles and are suitable for varying conditions.

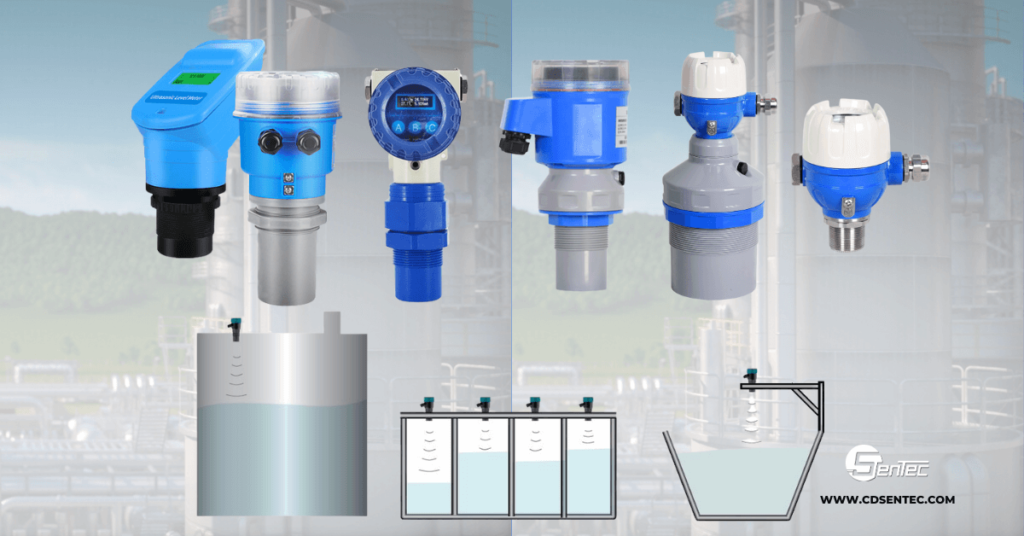

Understanding Ultrasonic Liquid Level Meters

How Ultrasonic Level Meters Work

Ultrasonic level meters use sound waves to measure the distance between the sensor and the surface of the liquid. The sensor emits ultrasonic pulses that travel through the air, reflect off the liquid surface, and return to the sensor. The time taken for the pulses to return is measured, and the distance is calculated based on the speed of sound in air.

Advantages of Ultrasonic Level Meters

- Cost-Effective: Ultrasonic level meters are generally more affordable than radar meters, making them a popular choice for budget-conscious applications.

- Easy Installation: These meters are relatively easy to install and configure, requiring minimal maintenance.

- Suitable for Clean Liquids: Ultrasonic meters work well with clean liquids and can be used in applications where the liquid is free from foam, vapor, or heavy dust.

Limitations of Ultrasonic Level Meters

- Environmental Sensitivity: Ultrasonic sensors can be affected by environmental factors such as temperature, humidity, and pressure, which can impact accuracy.

- Foam and Vapor Interference: The presence of foam or vapor can disrupt the ultrasonic pulses, leading to inaccurate measurements.

- Range Limitations: Ultrasonic meters have a limited range compared to radar meters, making them less suitable for very tall tanks or deep wells.

Understanding Radar Liquid Level Meters

How Radar Level Meters Work

Radar level meters use microwave radar waves to measure the distance to the liquid surface. The sensor emits high-frequency electromagnetic waves that travel through the air and reflect off the liquid surface. The time taken for the waves to return is measured, and the distance is calculated based on the speed of light.

Advantages of Radar Level Meters

- High Accuracy: Radar meters offer high accuracy and reliability, even in challenging conditions.

- Unaffected by Environmental Factors: Radar waves are not affected by temperature, pressure, or humidity, ensuring consistent performance.

- Suitable for Harsh Conditions: These meters can handle environments with foam, vapor, dust, and turbulent surfaces.

- Long Range: Radar meters can measure long distances, making them ideal for tall tanks and deep wells.

Limitations of Radar Level Meters

- Higher Cost: Radar level meters are generally more expensive than ultrasonic meters, which can be a consideration for budget-sensitive applications.

- Complex Installation: Installing radar meters can be more complex, requiring careful alignment and calibration.

Key Differences Between Ultrasonic and Radar Level Meters

Operating Principle

- Ultrasonic: Uses sound waves to measure distance.

- Radar: Uses microwave radar waves to measure distance.

Accuracy and Reliability

- Ultrasonic: Can be affected by environmental factors and surface conditions.

- Radar: Offers high accuracy and is less affected by environmental conditions.

Application Suitability

- Ultrasonic: Best for clean liquids without foam or vapor.

- Radar: Suitable for harsh conditions, including those with foam, vapor, and dust.

Cost

- Ultrasonic: Generally more cost-effective.

- Radar: Higher initial cost but offers superior performance in challenging environments.

Installation and Maintenance

- Ultrasonic: Easier to install and maintain.

- Radar: Requires more complex installation and calibration.

Choosing the Right Liquid Level Meter

When selecting between ultrasonic and radar liquid level meters, consider the following factors:

- Application Environment: Assess the presence of foam, vapor, dust, and other environmental factors.

- Accuracy Requirements: Determine the level of accuracy needed for your application.

- Budget: Consider the initial cost and long-term maintenance expenses.

- Range: Evaluate the measurement range required for your tanks or vessels.

- Installation and Maintenance: Consider the complexity of installation and ongoing maintenance requirements.

Conclusion

Both ultrasonic and radar liquid level meters have their unique advantages and limitations. Ultrasonic meters are cost-effective and easy to install, making them ideal for clean liquid applications. On the other hand, radar meters offer superior accuracy and reliability in harsh conditions, albeit at a higher cost. By carefully considering your specific application needs and environmental conditions, you can choose the right liquid level meter to ensure accurate and reliable measurements.

For more detailed information on our range of liquid level meters and to find the best solution for your needs, please visit our product page. Our experts are also available to assist you in selecting the right meter for your application.