The diaphragm seal pressure transmitter is the flange type pressure transmitter. This type of pressure transmitter, assembling diaphragm seals to field transmitters for the purpose of measuring pressure, differential pressure, level, and flow.

What Is a Diaphragm Seal?

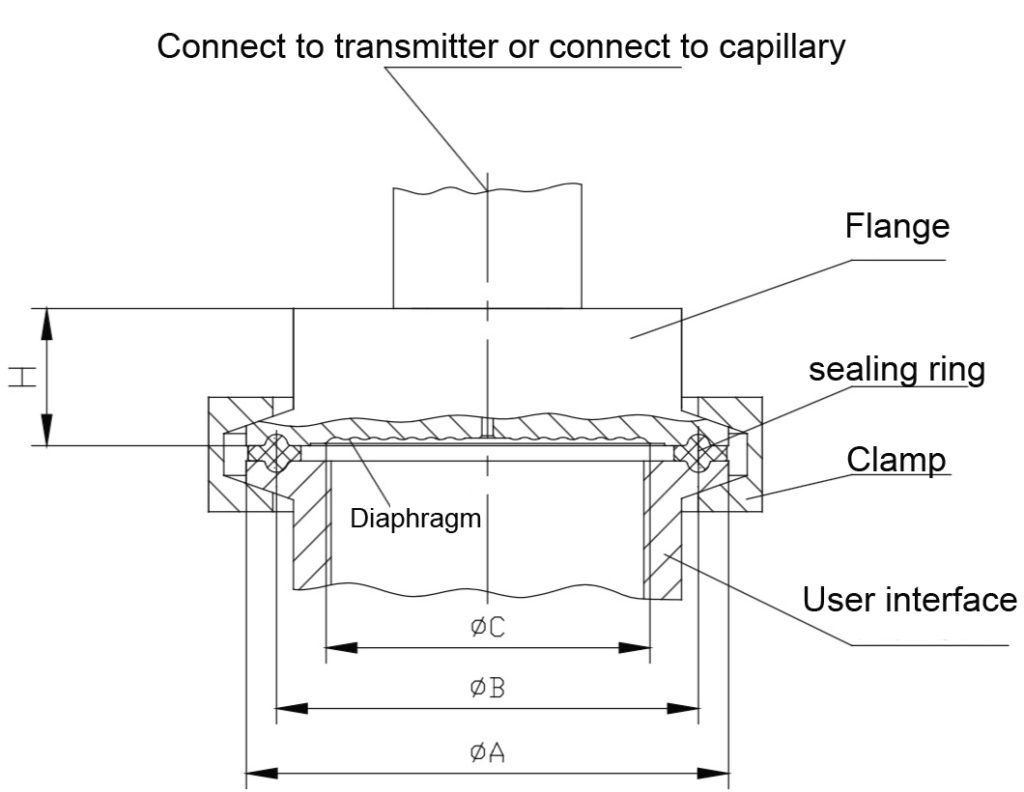

A diaphragm seal is a thin, flexible wall that separates the media being measured from the pressure measuring instrument. The space between the diaphragm and the measuring instrument is filled with a system fluid (transmitting fluid), which hydraulically transmits pressure from the flexible diaphragm.

Diaphragm Seals, also known as Chemical Seals or Gauge Isolators, are used to isolate pressure instrumentation, like pressure gauges, pressure transmitters, pressure switches, level transmitters, and more from process media that is hot, corrosive, clogging, or otherwise damaging to the pressure instrument.

Pressure transmitter isolating diaphragm types

Depending on the material of manufacturing and type of mounting, these remote seal pressure transmitter isolating diaphragm seals can offer varying performance. The performance capabilities/parameters of remote seals are as follows.

Metal Seals:

Stainless steel is the most common material for making remote seals, however, carbon steel and Hastelloy® C-276 is also used. The metal seals can handle pressures from 2500 psi to 5000 psi if thread mounted

Teflon Seals:

The Teflon seals can handle up to 1500 psi pressure. Being an FDA approved material, Teflon seals are also used in sanitary applications

Elastomer/Non-metal Seals:

These elastomer seals can perform up to 100psi. They can be made of different materials.

The above-mentioned performance capabilities are mentioned for temperature 100° F (38° C). The pressure being directly proportional to temperature, as the temperature varies, pressure values in the application would vary accordingly.

How Do Diaphragm Seal pressure transmitter system Works?

The diaphragm seals are connected to pressure equipment by direct capillary action. These seals act as an intermediate between the pressure equipment and the pressure media. The barrel or chamber encapsulates a fluid that transmits pressure from the pressure media to the diaphragm. Every time the pressure fluctuation from pressure media is experienced, the difference in pressure is exerted on the diaphragm. The pressure change on the diaphragm is then hydraulically transmitted to the pressure device or a sensor in order to record the reading. However, in some cases, the seals exert reverse pressure on the media. This pressure is equal to the amount of pressure transmitted from the pressure media. The reverse pressure exerted by the diaphragm seal is then considered as the reading by a pressure sensor or measuring equipment.

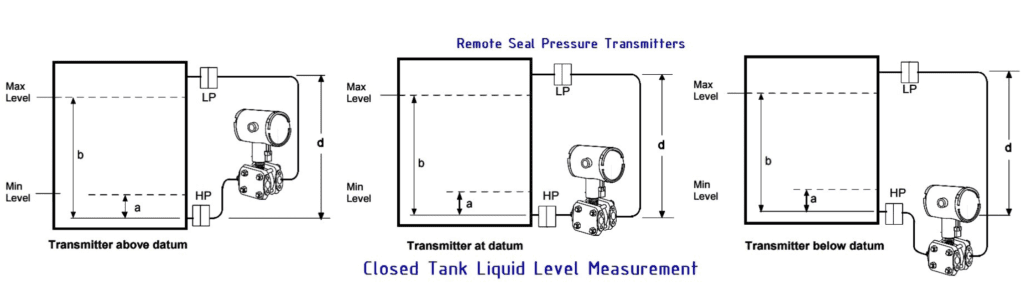

Diaphragm seal systems respond to changes in both process pressures as the level changes in the tank, and in static pressure over the liquid. These variations in pressure are transmitted through an oil- filled capillary to a differential pressure transmitter-sensor. The capillaries and seals are filled with incompressible oil compatible with the process temperature, pressure, and media composition. The diaphragm seal pressure transmitter is commonly mounted at grade, or in close proximity to the high-pressure process connection. The change in level in tank or vessel in-turn effects the HP & LP pressure points and this change in pressure will be measured using a differential pressure transmitter and then calculates equivalent level of the tank or vessel.

What are the advantages of diaphragm seal pressure transmitter?

The purpose of a diaphragm seal is to isolate a pressure measuring instrument from the process media. It is often used for the most difficult measuring tasks, here we list some most significant advantages of diaphragm seals pressure transmitter.

(a).Minimally affecting accuracy: A properly engineered diaphragm seal protects while only minimally affecting accuracy. As such, diaphragm seals extend the operating life of pressure measurement instruments – saving users significant time and money in the long run.

(b).Various process connections: Diaphragm seals also enable remote mounting from the pressure port via a capillary that is custom suited for your unique application. And thanks to the wide range of available process connections (flanged, threaded, etc.), they can meet many industry standards.

(c).Challengeable measurement media: When using a diaphragm seal, the measuring instrument can be used at temperatures from −130 to +750°F (−90 to +399°C), as well as with aggressive, corrosive, heterogeneous, abrasive, highly viscous, or toxic media. For hot temperature measurement, the condensate pot for pressure transmitters is necessary in some cases.

(d).Ultra low pressure with accurate measurement: Diaphragm seals offer the advantage that the “contact surface” between pressure medium and diaphragm is relatively large. Thus ensuring accurate pressure measurement, especially for very low pressures (< 600m bar). And, low pressure transmitter can be easily dismounted, e.g. for cleaning or calibration purposes. What’s more, The contact surface between the media and the diaphragm is relatively large, which ensures more accurate pressure measurements.

What Are the Industrial Applications of diaphragm Seals?

Diaphragm seals typically protect the pressure transmitter from one or more damaging aspects of the process media. The suitable application of diaphragm seal system for measuring liquid level, density, flow and pressure are like follows:

- high/low temperature fluids

- highly corrosive/high viscosity fluids

- the fluids which may cause clogging of impulse piping in the low temperature

- toxic fluids

- the fluids containing suspended solids which are deposited in the impulse piping and may cause clogging.

Diverse pressure measurement

Due to diaphragm seal outstanding features for above challenging application cases, compared with the inline pressure transmitter who is the pressure transmitter installation on pipe only, the diaphragm seal pressure transmitter are more diverse for the Differential, Gauge or Absolute pressure measurement.

For applications under vacuum, the diaphragm seal pressure vacuum transmitter is mounted below the high-pressure connection to reduce vacuum effects on the transmitter fill fluid. The minimum capillary length is dictated by the distance between the mounting position of the transmitter and the low-pressure connection. All cavities within the assembly are oil-filled including the diaphragm, capillary, and diaphragm seal pressure transmitter body. Although manufacturing techniques help ensure a high-quality fill, temperature-induced errors are inherent to diaphragm seal systems.

Liquid Level Measurement : Closed Tank

The differential pressure transmitter capillary type can be used for level measurement. Determine the minimum and maximum pressure differentials to be measured

At Minimum Level i.e.

PMin = (SGp x a) – (SGf x d)

i.e. LRV when HP at bottom of tank

i.e. –URV when LP at bottom of tank

PMax = (SGp x b) – (SGf x d)

i.e. URV when HP at bottom of tank

i.e. –LRV when LP at bottom of tank

Where:

minimum level at 4mA

maximum level at 20 mA

a = distance between bottom tap and minimum level

b = distance between bottom tap and maximum level

d = distance between taps

SGf = Specific Gravity of capillary fill fluid

SGp = Specific Gravity of process fluid

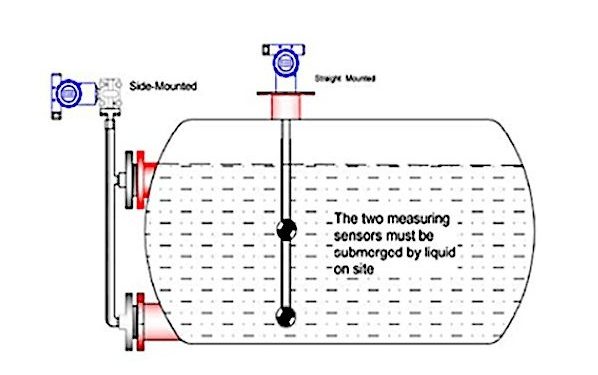

Density or Interface Measurement

Calculate the minimum and maximum pressure differentials to be measured

Pmin = (SGmin – SGf) x (d);

minimum density, 4mA output

Pmax = (SGmax – SGf) x (d);

maximum density, 20mA output

Where: d = distance between the taps

SGmax = maximum Specific Gravity

SGmin = minimum Specific Gravity

SGf = Specific Gravity of capillary fill fluid

Note: The Pmin & Pmax are nothing but LRV & URV of the diaphragm seal pressure transmitter. These to be calculated and entered in the Remote seal Differential Pressure Transmitter during calibration

Conclusion

The diaphragm seals (referred to as chemical seals), mounted with process transmitters, level transmitter, density transmitter etc., are recognized and valued internationally for the most difficult of measuring tasks. The optimal diaphragm seal designs, materials and filling media are available for each application. SenTe oem pressure transmitter can be used at extreme temperatures from -90 to +400 °C and with aggressive, corrosive, heterogeneous, abrasive, highly viscous or toxic media. rosemount pressure transmitters substitute also available.