The flow switch sensor is mainly installed on-line or plug-in in medium pipelines such as water, gas and oil to monitor the water flow in the water system. When the water flow is higher or lower than a certain set point, the output alarm signal is triggered and transmitted to the unit, and the system can make corresponding indication actions after obtaining the signal. Avoid or reduce host “dry burn”.

Types of flow switch sensor

Baffle type: Baffle type flow switch or plug-in flow switch is also called mechanical flow switch.

Thermal flow switch: Thermal flow switch is also known as electronic flow switch.

Piston flow switch: The piston flow switch is an on-line installation, mechanical flow switch. For liquid or gaseous media.

How the flow switch works ?

The working principle of the water flow switch When there is water flowing in the water flow switch, and the water flow rate is ≥1.0L/min, the magnetic core in the water flow switch is pushed by the water flow to produce displacement, and the magnetic core displacement drives the magnetic source to produce a magnetic control effect, so that the water flow switch outputs “on”. “Signal. The automatic selection of the flow switch is included in the quick and easy selection. The signal is input to the equipment control system, and the control system realizes the control function. When the water flow is less than the starting flow, the water flow switch outputs a “off” signal. The control system produces the opposite control action to the above. In other words: water flow switch When the flow rate of water in the pipeline is greater than 1L/min, the magnetic core will be displaced under the action of water flow and drive the magnetic source to produce a magnetic control effect, so that the sensor outputs a “1” switch signal, which is input to The equipment control system realizes the purpose of water flow control after power expansion. When the water flow in the pipeline is less than 1L/min, the magnetic core drives the magnetic source to return under the action of the return spring, so that the sensor outputs a “0” switch signal and stops the system. The flow switch has the advantages of high sensitivity and strong durability.

Electronic flow switch working principle:

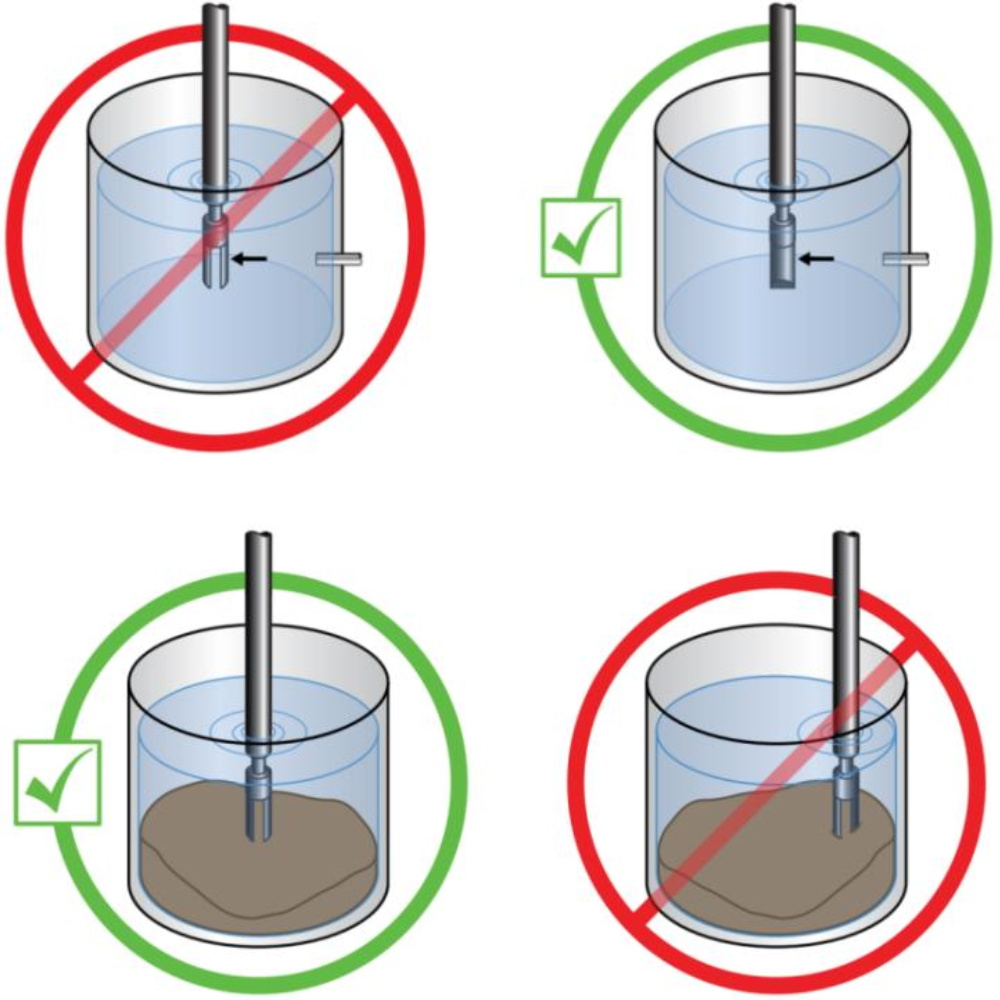

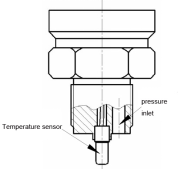

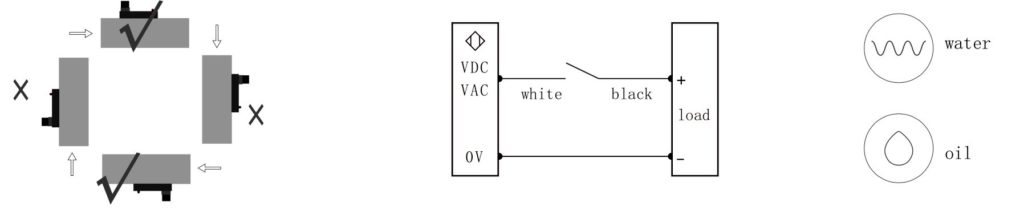

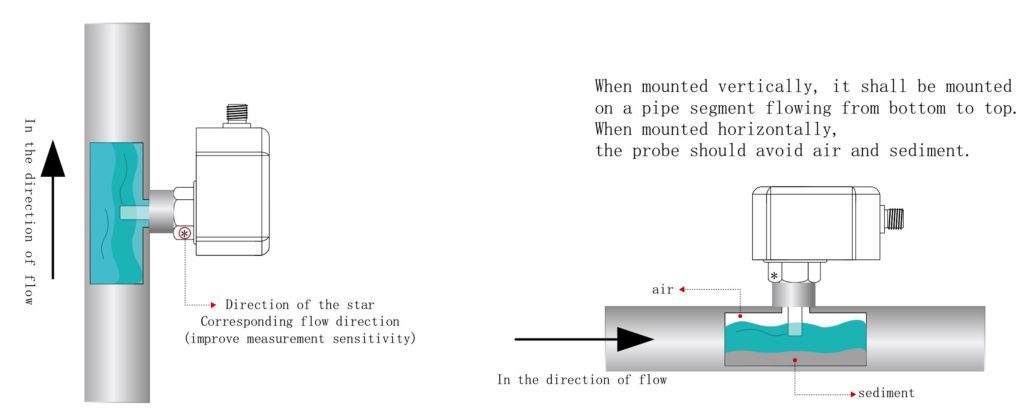

The electronic flow switch is also a heat conduction flow switch. The thermal flow switch is designed based on the principle of temperature change of the probe head. The probe has a built-in heat sensor and thermal sensor, and is in contact with the medium. During measurement, the heat sensor emits constant heat. When there is no medium flowing in the pipe, the heat received by the heat sensor is a constant value. When there is a medium flowing, the heat received by the heat sensor will vary with the flow rate of the medium. The thermal sensor converts the temperature difference signal into an electrical signal, and then converts it into a corresponding contact signal or an analog signal through the circuit.

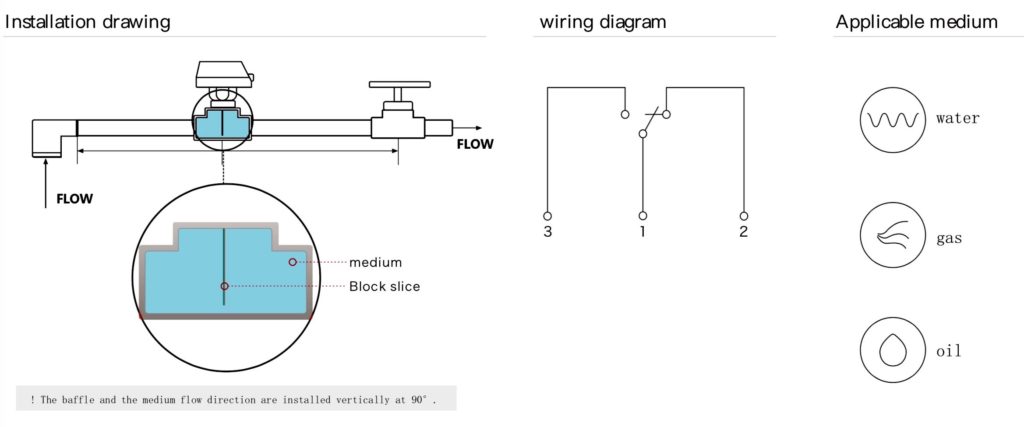

Baffle type flow switch working principle:

The baffle type flow switch is used to detect air, oil and water flowing in one or two directions, and there should be no entangled debris in the medium. When the fluid flows through the pipeline, the baffle is deflected, and by adjusting the adjusting bolt, the SPDT micro switch operates on the set flow and outputs the switch signal;

Mechanical piston flow switch working principle:

The piston flow switch comprises a casing that houses a piston equipped with a permanent magnet. The pressure difference resulting from the liquid flow exerts force on the piston, causing it to drive the internal sealing magnet and switch. The starting flow is determined by the diameter of the piston. In cases of reduced flow, a stainless steel spring resets the piston to its original position. Activation of the reed switch allows for remote alarm or indication transmission, suitable for both liquid and gaseous media. The switch is available in various housing options, including solid plastic, aluminum, or stainless steel.

What are the advantages of the flow switch sensor ?

Advantages of flow switches

(1) Low flow rate (volume) action of water flow switch

(2) The water flow switch has a simple structure and a small action contact surface.

(3) The water flow switch is also applicable to the water flow with low content of debris

(4) When the special debris of the water flow switch is blocked, it can be removed online

Switch signal VS Analog signal VS Voltage signal VS Current signal

Switch (D): It is a digital signal, which is two states of switch: high level and low level (ie on and off, 1 and 0, etc.);

Analog (A): It is an analog signal, that is, a general voltage or current signal.

Voltage signal: measure the flow and convert it into a 1-5V voltage signal, which is an analog quantity.

Current signal: measure the flow and convert it into a 4-20mA current signal, which is also an analog quantity.

FLOW SWITCH SENSOR APPLICATION

*The flow switch is mainly installed on-line or plug-in in medium pipelines such as water, gas and oil to monitor the flow of water in the water system.

*Flow switch gas-liquid dual-purpose type, can be widely used in industrial automation/mechanical equipment/air compression industry/refrigeration and air-conditioning fields, and industrial applications are specifically used in water-cooled welding machines, laser equipment cooling systems, vacuum coating machines, electric furnaces, polysilicon casting Ingot furnace, etc. The water flow switch magnet is not in a flowing waterway and can be used in sewage systems and works properly.

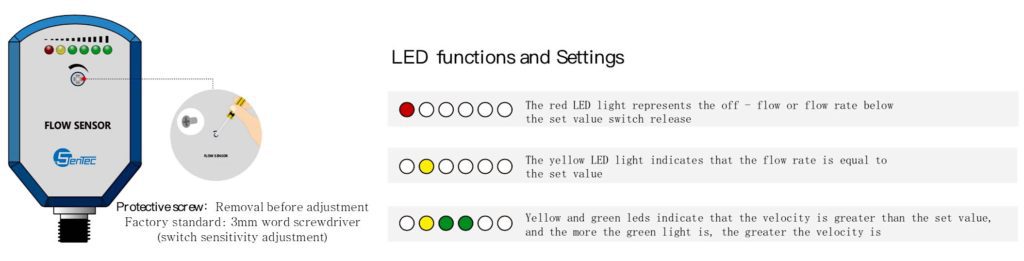

* The flow switch can monitor the liquid flow in the pipeline in real time, provide switch output, and use 6 LEDs to display the fluid flow rate status in real time, to achieve the following monitoring functions:

a. Medium flow, reduce/increase flow rate;

b. Medium presence/absence;

c. Medium flow/still;

d. It can be used to monitor the fluid flow rate in the pipeline, monitor the interruption of flow, or prevent the idling of the pump. It is widely used in various industries where it is necessary to monitor the fluid flow rate in the pipeline or protect important equipment when the liquid flow fails.

※Note: As one of the earliest flow meter manufacturer, SenTec provide a wide variety flow measurement solutions, such as differential pressure flow meters, Calorimetric Flowmeter, liquid flow sensor, Ultrasonic Level Transmitter, mass flow meter, Variable Area Flowmeter or Rotameter, Electromagnetic Flowmeter, Turbine Flowmeter, Vortex Flow Meter, Thermal Flowmeter, Coriolis Flowmeter, Mass Flowmeters, Open Channel Flowmeters etc.

For specific flow switch sensor price, please contact our sales engineer.