What are the biopharmaceutical process analysis sensors?

What are the biopharmaceutical process analysis sensors ?Biopharmaceuticals involve production processes, reactor formats employed, process analytical methods, quality control and digital factories. Among them, the process analysis method includes the development trend from offline standard QC detection method to near-line detection, to the final online and real-time sensor monitoring.

Table of Contents

Backgroud: biopharmaceutical process analysis sensors

Biopharmaceutical process analysis sensors play a crucial role in the pharmaceutical industry. Biopharmaceuticals refer to the use of research results of microbiology, biology, medicine, biochemistry, etc., from organisms, biological tissues, cells, organs, body fluids, etc., comprehensively using microbiology, chemistry, biochemistry, biotechnology, pharmacy and other sciences. The principles and methods of manufacture of a class of articles for prevention, treatment and diagnosis.

Biopharmaceutical raw materials are mainly natural biological materials, including microorganisms, human body, animals, plants, marine organisms, etc.

The use of biopharmaceutical process analysis sensors in the pharmaceutical industry helps in monitoring and optimizing processes, leading to improved efficiency and quality control.

Biopharmaceutical smart sensor features

Biopharmaceuticals involve production processes, reactor formats employed, process analytical methods, quality control and digital factories. Among them, the process analysis method includes the development trend from offline standard QC detection method to near-line detection, to the final online and real-time sensor monitoring.

Characteristics of aqueous solution testing in production workshops in the fields of biopharmaceuticals and chemical synthesis:

1. In hazardous situations, explosion-proof models are required;

2. FDA and other sanitary certification;

3. High temperature and high pressure above 130℃, suitable for steam cleaning;

4. Installation on the top or side wall of the tank, pluggable sheath

Biopharmaceutical pH and DO (dissolved oxygen) sensors

As one of the underlying equipment management of the digital and intelligent engineering of future biopharmaceutical factories, intelligent sensors are worthy of attention. This article discusses pH and DO (dissolved oxygen) sensors commonly found in biopharmaceuticals.

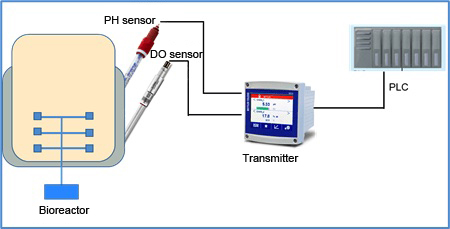

As shown in the figure above, pH and DO online sensors are widely used in the online monitoring of pH and DO in cell culture, and the measurement system generally includes sensors and transmitters. In the process of using electrodes, process development or production personnel generally care about the following two core issues: Can the electrode measure accurately and reliably? How long will the electrodes last?

First: Are the electrodes able to measure accurately and reliably?

For the sensor: pH sensitive membrane impedance, reference system, diaphragm performance; electrochemical oxygen internal electrode, dissolved oxygen membrane performance; optical dissolved oxygen fluorescent coating, etc. will determine the zero point and slope of the corresponding electrode, generally through The zero point and slope can judge whether the sensor can measure accurately; for the transmitter: it is responsible for the modulation and transmission of the signal, the calibration and adjustment of the measurement loop, and also indirectly determines whether the sensor can accurately measure pH and DO, and even connect The transmission cable will also indirectly affect the accuracy of the measurement;

Therefore, to judge whether the sensor can measure accurately, it is required that the sensor and the transmitter can provide performance diagnosis. The bottom-level requirement is that the sensor implements ADC (Analog-to-Digital Convert), that is, the sensor outputs an analog signal from the traditional The transition to outputting a digital signal. Combined with the related functions of the transmitter, accurate measurement can be achieved.

Second: How long will the electrodes last?

Taking a pH sensor as an example, the same type of sensor has the same sensitive membrane, reference system, and diaphragm, and the theoretical service life is similar, but the process of the sensor is different, such as batch culture or continuous flow plus culture, is it easy? The measurement environment of fouling, how many times SIP has been experienced, how many times high temperature sterilization, etc., these factors ultimately determine its actual life. And for this information, if the electrodes do not implement ADC, it is difficult to collect and store relevant information.

SenTec high-precision pH sensors feature small drift, fast response, short polarization time, long maintenance cycle, and greatly reduced operating costs. Biopharmaceutical high-temperature sterilization DO sensor adopts polarographic high-concentration oxygen measurement, with high accuracy, reliability and cleanliness. It is used in fermentation tanks, biotechnology, pharmaceutical industry, food and beverage technology, sugar production, starch slurry, etc.

Subscribe To get new products and solutions

Latest Posts

Dissolved Oxygen Sensor Selection: Proven Tips for Better Water Monitoring Results

Underwater Ultrasonic Sensors: Essential Guide for Real Projects