- Tel: +86 28 87436908

- Email: info@cdsentec.com

Wastewater treatment process instruments are devices used to monitor and control various parameters during the treatment of wastewater. These instruments play a crucial role in ensuring the effectiveness and efficiency of the treatment process.

In water and wastewater management industry, the wastewater treatment inlet pumping station plays a crucial role in the overall wastewater treatment process. It is responsible for pumping the wastewater from the collection system into the treatment plant.

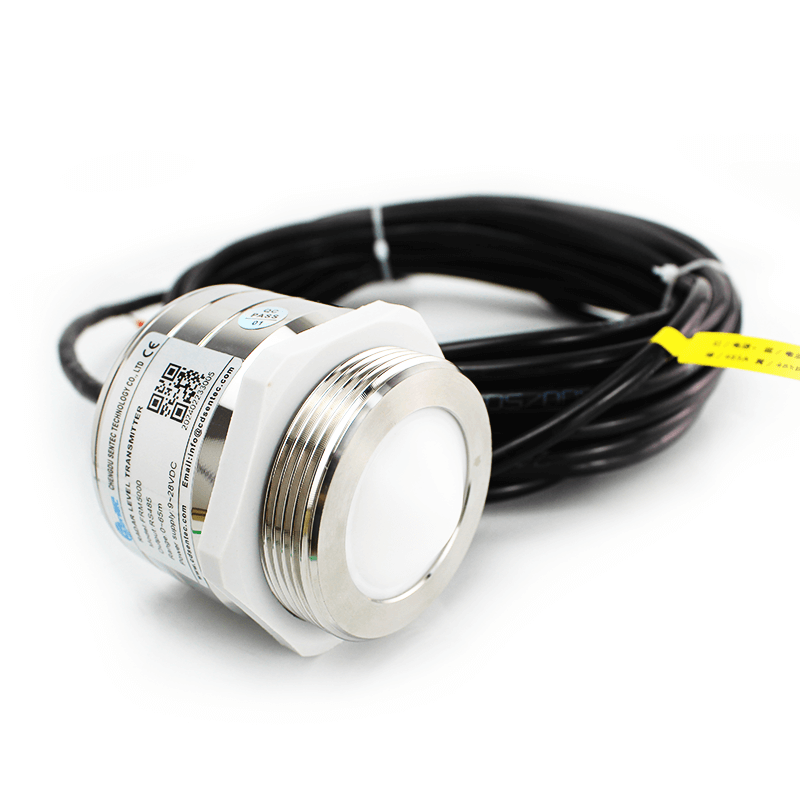

Wastewater from households and businesses, together with surface water, is carried to the wastewater treatment plant via an extensive sewer network. If the natural gradient is not steep enough, numerous pumping stations are required to create a sufficient height difference. The level measurement in the inlet shaft is used for cost-effective control of the pumps.

Accurate monitoring of the river level is an important prerequisite to be able to react quickly and correctly in the event of a flood. Data recording and transmission via radio link is the optimal solution for getting level information on rivers in remote areas without power.

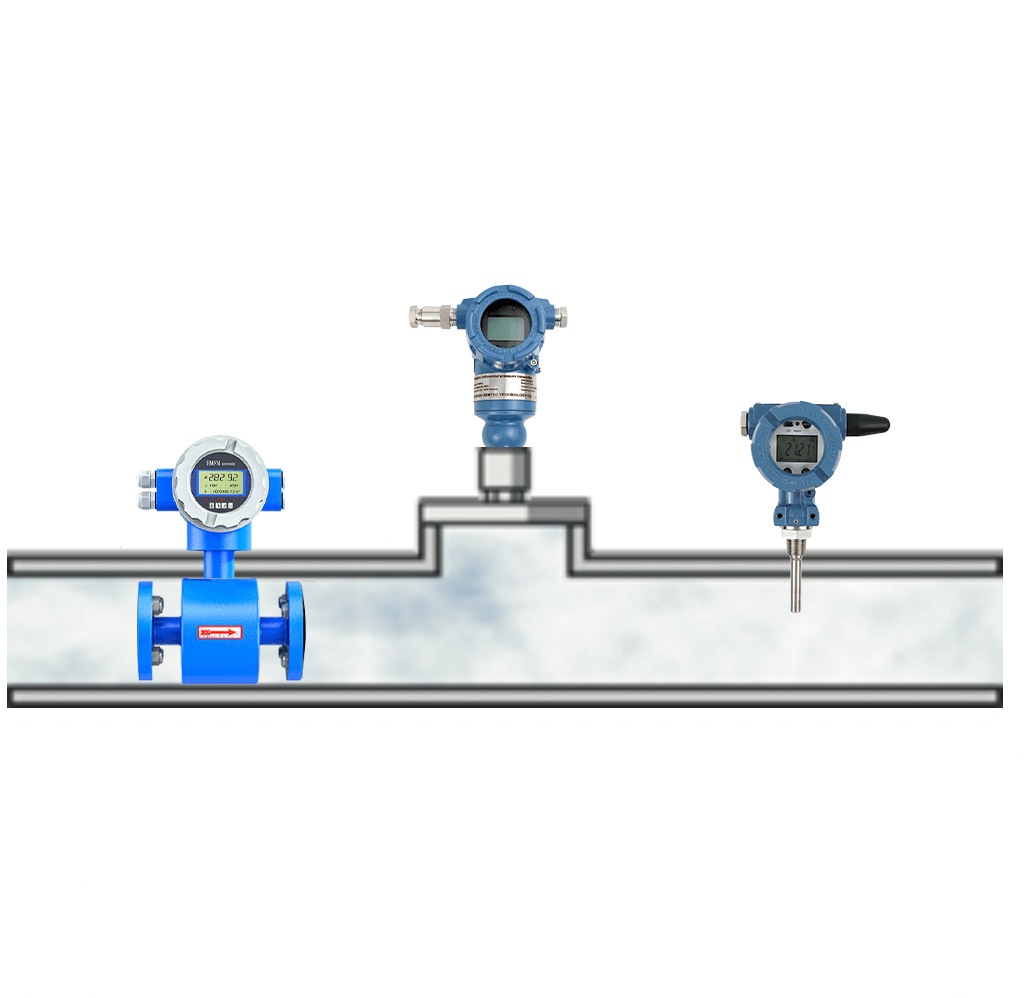

Sewage and rainwater are often transported to the treatment plant in open collection channels or flumes. The flow rate is measured at various points in these channels. Measurement of the water flow at the inlet and outlet of the treatment plant is the basis for the calculation of tariffs and operating costs.

Wastewater from households and industrial operations is carried through a sewerage system to the clarification plant. In large sewer systems, the water levels are monitored at key points in the network. Level measurement in the sewer allows an accurate assessment of the degree of utilization of the conduit system.

Inlet pumping stations play a critical role in various industries, such as water treatment plants, oil refineries, and chemical processing plants. These stations are responsible for pumping the incoming raw material or feedstock into the system for further processing.

Wastewater treatment additives are substances or chemicals that are used to enhance the efficiency and effectiveness of the wastewater treatment process. These additives can assist in various aspects of wastewater treatment, including coagulation, flocculation, disinfection, and odor control.

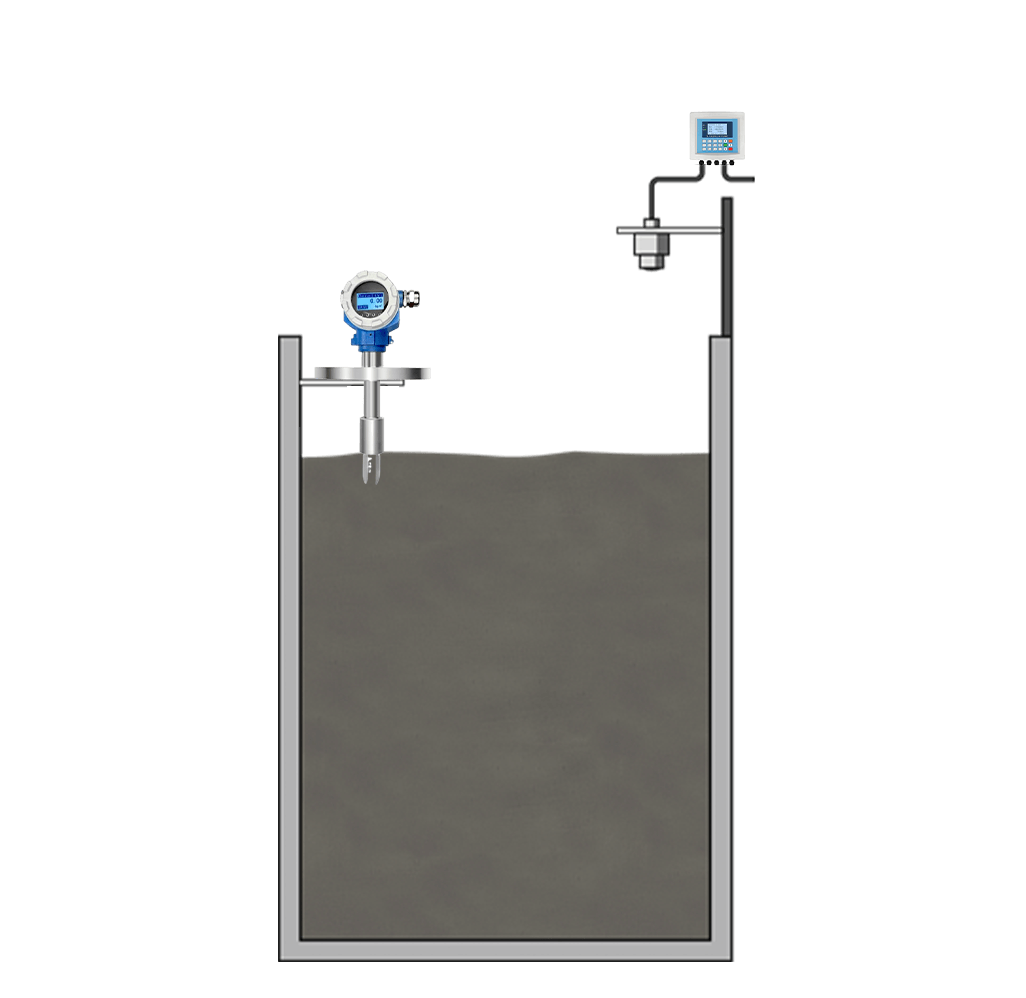

Through the addition of chemicals, phosphates in the wastewater are precipitated out, for example in primary sedimentation, in aeration systems or in special precipitation and secondary clarifiers. Precipitants like ferric chloride bind the phosphate chemically and deposit it in the sludge. In the storage tanks for these chemicals, a level measurement and point level detection system is deployed for continuous inventory control and optimal dosage.

In the nitrogen and phosphorus removal stage, lime is used to stabilize the pH value. Stored in silos, the lime is added to the wastewater as a solid or as an aqueous suspension. The silo content is measured by a radar sensor and a point level sensor detects the maximum level and transmits a full signal.

To protect the process pumps, any leakage water, e.g. arising from a faulty pump seal, is detected and an alarm triggered. The pressure in the pipe is measured directly at the pump and displayed in the control system of the WWTP. Any malfunctions are detected quickly.

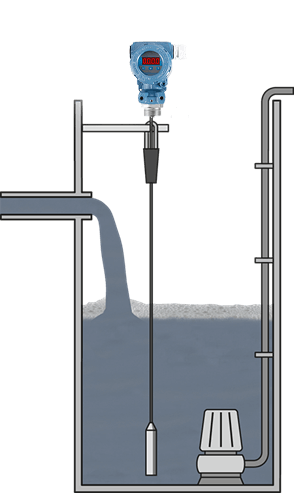

The process water is collected in tanks or open basins. Pressure pumps deliver the water for cleaning and rinsing purposes to various locations in the wastewater treatment plant. To ensure an optimal supply of water, the level in the process water tank is measured continuously.

In the process of monitoring and controlling the wastewater treatment process, various instruments can be used. These wastewater treatment additives process instruments include level instruments, flow instruments, pressure instruments, and water quality monitoring instruments.

Before the sludge enters the digestion tower, it is stored in large vessels. During storage, the sludge is dewatered and thickened sometimes scrapers and agitators are used to accelerate the process.

Through drying, the weight and volume of the sludge is further reduced. In the thermal drying unit, which is equipped with a belt drier and a hot (+80 to +130 °C) air stream, water is removed from the sludge through evaporation. The continuous monitoring of belt loading is done by means of radiometric, i.e. radiation-based, measurement – this technique allows optimal, cost-effective dryer control.

After thermal drying, the sludge is stored in silos for further use. The granulated product is deposed of in landfills, used in agriculture or burned for energy generation. The level measurement and point level detection ensure that the container volume is optimally utilized.

The digested sewage sludge is pumped into a sludge storage tank. This tank serves as an intermediate storage facility before the sludge is fed to the centrifuge or pressed for mechanical dewatering. To ensure optimal feeding, the sludge volume is monitored by a level measuring instrument and sludge content is measured by a composition analysis instrument.

The sludge treatment process requires various instruments to monitor and control the different stages. They meets safety standards, such as explosion-proof instruments, to prevent accidents. Standards like ATEX and IECEx ensure the safety of instruments used in potentially hazardous environments

Digester, biogas storage facility, gas pipeline gas processing is a critical aspect of wastewater treatment to ensure the safety of personnel and comply with regulations.

The methane gas extracted from the digestion tank is temporarily stored in a gas reservoir. Depending on the design of the gas storage facility, either a flexible diaphragm of plastic or a floating roof is used for volume equalization. The gas volume and gas pressure are measured continuously to ensure reliable and safe operation.

The biogas generated from sewage sludge is used for environmentally friendly production of heat and electricity. It is transported to the storage tanks through a gas pipeline.

The organic components of sewage sludge are decomposed under anaerobic conditions in heated, closed digestion tanks. In the process, combustible gases such as methane are released from the sludge. These are collected in a biogas tank and then converted into electricity and heat in cogeneration (CHP) plants. A level sensor controls the filling of the digester. To ensure that no foam gets into the gas system along with the collected gas, a point level sensor is used for monitoring.

Gas processing in wastewater treatment is of utmost importance for the safety of personnel and the proper functioning of the treatment processes. Gas monitoring instruments play a vital role in ensuring the safe operation of wastewater treatment plants and compliance with regulations.

SenTec online resource library is a place you can know more knowledge from video, cases study, e-book etc.