Sensor to measure Diesel Fuel

What sensor to measure Diesel Fuel? Fuel is the fuel used in fuel-fired engines, mainly divided into gasoline and diesel. The sensor to measure the diesel fuel have the diesel fuel pressure sensor, diesel fuel density meter, diesel fuel flow meter etc.

Table of Contents

Backgroud: sensor to measure Diesel Fuel

Fuel is the fuel used in fuel-fired engines, mainly divided into gasoline and diesel.

Diesel is a light petroleum product, a mixture of complex hydrocarbons (about 10 to 22 carbon atoms), and is a diesel fuel. It is mainly prepared from diesel fractions produced by crude oil distillation, catalytic cracking, thermal cracking, hydrocracking, and petroleum coking. It can also be produced by shale oil processing and coal liquefaction, and is divided into two categories: light diesel oil (boiling point range of about 180-370 °C) and heavy diesel oil (boiling point range of about 350-410 °C). Widely used in large vehicles, railway locomotives, ships.

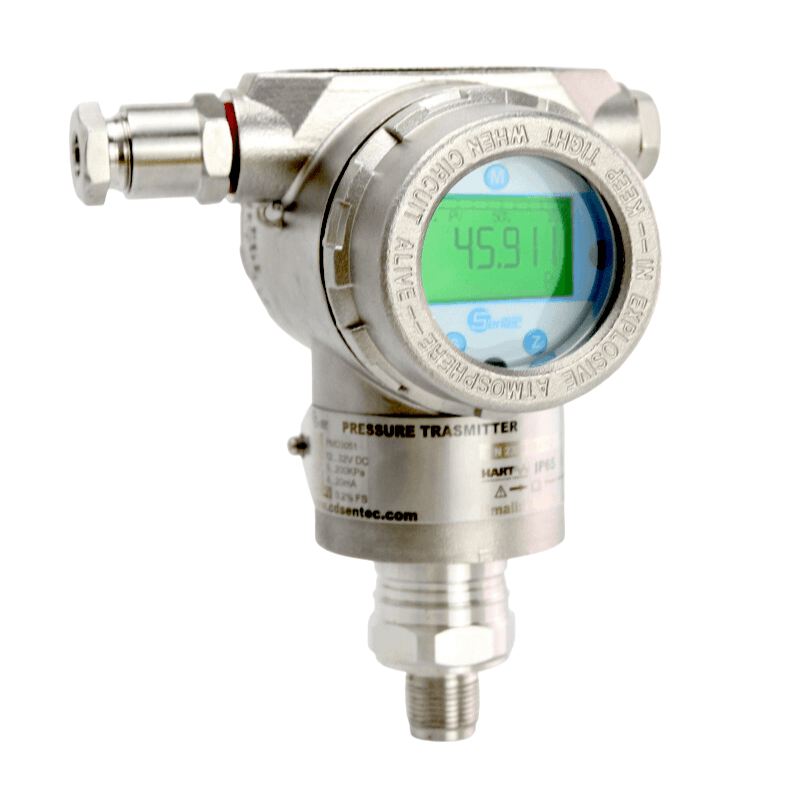

Diesel Fuel Pressure Gauge

The function of the diesel fuel pressure gauge is to show the changes in the oil pressure of the lubricating system. The oil pressure is an important indicator of the lubrication system, its level is a sign of the strength of the lubrication. General engine fuel pressure is specified in the range of 0.15-0.3 MPa. There are two kinds of common diesel fuel pressure gauges: elastic tube diesel fuel pressure gauges and electric heating diesel fuel pressure gauges.

The elastic pipe diesel fuel pressure gauge consists mainly of a curved, oval shaped brass elastic tube and head. One end of an elastic flat tube (also known as an expansion tube) is connected by a tubing to a lubricating oil channel, the other end is closed, and the connecting rod is connected with the fan gear. The shaft is equipped with a pointer and a gear, and the gear is engaged with the fan-shaped gear. After the starting of the internal combustion engine, when the oil pressure in the oil channel rises gradually, the oil enters the elastic flat tube, making the elastic flat tube deformed in the direction of straightening. When the sector gear is driven by the connecting rod, it rotates in an anticlockwise direction, so the gear drives the pointer to rotate in a clockwise direction, so that the pointer points to the scale with high oil pressure. When the oil pressure in the oil channel is reduced, the elastic flat tube is closed inward, through the connecting rod and the fan-shaped gear, so that the gear and the pointer are rotated in the counter clockwise direction. The pointer then points to the lower scale of the oil pressure. The internal combustion engine stops working, the pressure in the elastic tube disappears and the pointer goes back to zero.

The electric diesel fuel pressure gauge of the electric heating diesel fuel pressure gauge is to control the current size by using the change of oil pressure. Then the thermal effect of the current is used to deform the bimetal strip and move the needle to measure the value of the oil pressure. The electric diesel fuel pressure gauge consists of two parts: the sensor and the indicator table. The sensor is connected with the main oil channel of the internal combustion engine, and the indicator is mounted on the instrument panel, which is connected by a wire.

Diesel Fuel online densitometer

In the process of oil extraction, all liquids and oils need to be tested for density or concentration, which requires an online density meter. SenTec Intelligent online density meter (also called online density transmitter) is a device for continuous online measurement of the concentration and density of liquids, which can be directly used in industrial production processes. Commonly used industrial online liquid density meters include static pressure density meter, vibration type density meter and laser density meter. According to installation, it can divided into tank densitometer and pipeline densitometer.

Advantages of online liquid diesel fuel densitometer:

*The use of industrial-grade high-performance micro-controller integrated circuit, high accuracy, good stability, strong anti-jamming ability.

*Power supply using isolation circuit design, wide-format precision power supply, impact resistance, anti-jamming.

*”Plug and use, maintenance-free” measurements for monitoring and controlling continuous measurements

*Sensor signal with photoelectric compartment design with 4-20 mA output, connectivity PLC control system

*Long rod type is suitable for use in open and sealed tanks and cans up to 2m in length

*Explosion-proof certification

Subscribe To get new products and solutions

Diesel Fuel flowmeter

We supply in-line mechanical or digital diesel fuel flow meter. Liquid turbine flow meter, oval gear flow meter also coriolis flow meter is often requested flow instruments for diesel flow measurement. Oil flow meter is from China leading flow meter manufacture with rugged construction also fast delivery time.

The most important use of diesel is for diesel engines for vehicles and ships. Compared with gasoline, diesel has high energy density and low fuel consumption rate. Diesel fuel has low energy consumption, so some small cars and even high-performance cars also use diesel. Diesel is flammable, volatile, and insoluble in water, soluble in alcohol and other organic solvent. Customers need diesel flow instruments to monitor diesel fuel consumption in the automotive, marine, portable fueling and power generation industries and so on.

Types of diesel fuel flow meter types:

1).Oval gear flow meter for diesel flow measurement

Positive displacement flow meter (PD flow meter)

Can be made into mechanical type diesel oil flow meter or with flow transmitter option

High accuracy, bulky size and robust construction

In-line fuel flow meter with various material options, cast iron, cast steel, stainless steel

No straight pipeline needed when installation the oil flow sensor

High accuracy: 0.5% or 0.2% option

Can with various outputs, such as 4-20mA, pulse or Hart, Modbus

Sensor size from DN10 to DN200 (8 inch diesel fuel flow meter)

2).Turbine flow meter (TUF) for diesel flow measurement

Low cost and compact size digital diesel flow meter

Option with electronic displays: Battery operated or 12 or 24V DC external power

Stainless steel oil flow meter

Various process connection: thread, flange or tri-clamp connection

Sensor size from DN6 to DN200 (8 inch turbine flow meter)

Various sizes available: from simple and economical turbine sensor to turbine transmitter with various outputs and digital display

3).Coriolis mass flow meter for diesel oil flow metering

Indeed direct accurate mass flow measurement

High accuracy: 0.15%~0.2%

Various parameters detected by only one Coriolis sensor: diesel mass flow, density, temperature

Reliable and excellent performance, used in custody transfer

All 316L stainless steel material

Inline diesel fuel flow meter

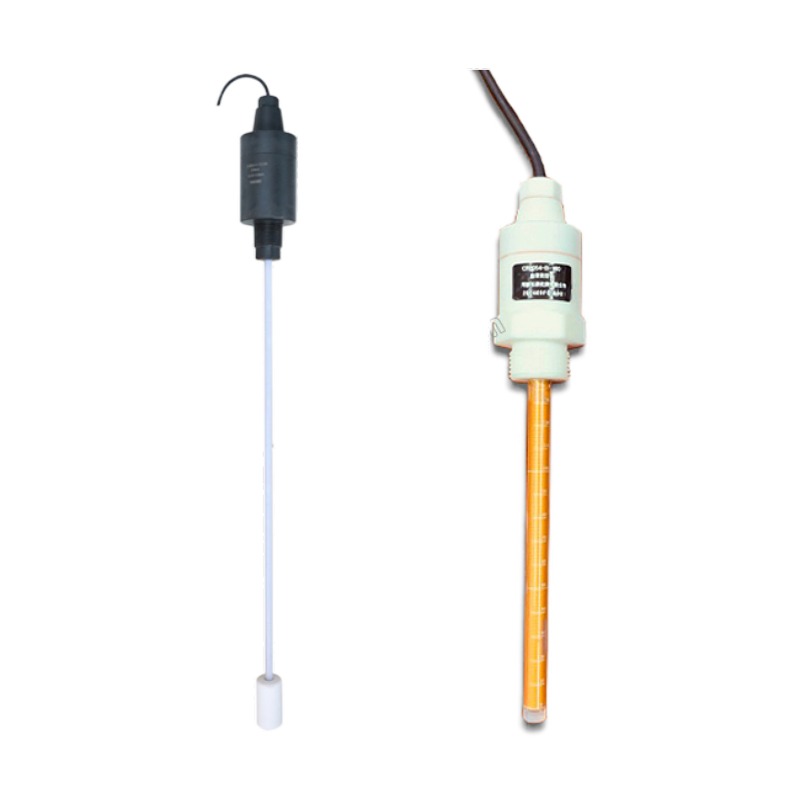

Diesel Fuel level sensor

The principle of capacitive flue level sensor is the linear change of the capacitance generated by the entered liquid medium between positive and negative electrodes — the capacitance change (the change of liquid level) is then converted into standard electrical signal. The core components of the product are highly integrated, exclusive capacitance measurement chips. Through accurate temperature compensation and linearity correction, they are characterized by high independence, high accuracy, high stability and high continuity.

The capacitive fuel level sensor outputs the linear change of the liquid level, utilizing the change rule of the capacitance formed between electrodes and containers. The level of the liquid can be directly displayed or transmitted to the remote monitoring system via wireless transmission. The sensor does not need to be reset when the medium or the installation environment changes, for it can automatically adapt and remain unaffected to the dielectric constant and temperature change.

At the same time, the fuel level sensor can continuously detect the level, with the resolution rate less than 1 mm. The length can be truncated to adjust the height of the tank. And it is easy to install with no additional screw needed for fixation. With wide voltage input, it is not limited by voltage in various situations.

Subscribe To get new products and solutions

Fuel Temperature Sensor

A typical unit pump is equipped with a fuel temperature sensor. The fuel temperature will affect the fuel density, which will then affect the fuel injection. When the fuel temperature increases, the fuel density increases correspondingly while the actual amount of the injected fuel decreases, with the engine power being affected.

In the mechanical line pump or proportioning pump, there are, more or less problems caused by fuel density. Electronic control unit pump system, therefore, adopts the fuel temperature sensor. The ECU will control the opening and closing time of the electromagnetic valve to control the quantity of fuel injection according to the fuel temperature, eliminating the influence of fuel temperature on fuel injection.

Latest Posts

Dissolved Oxygen Sensor Selection: Proven Tips for Better Water Monitoring Results

Choosing the wrong dissolved oxygen sensor can lead to catastrophic failures: fish suffocating in aquaculture systems or bacteria dying in wastewater treatment plants, halting decomposition.

Clamp-On Ultrasonic Flow Meters: A Practical Guide

Clamp-on ultrasonic flow meters have changed how we measure liquid flow in pipes. These non-intrusive devices provide accurate flow measurements without cutting into existing piping

Underwater Ultrasonic Sensors: Essential Guide for Real Projects

Underwater ultrasonic sensors work reliably in muddy or polluted water where traditional optical methods fail completely. These specialized sensors employ sound waves to detect objects

The Truth About Acoustic Doppler Current Profiler: From Shallow Streams to Ocean Depths

Acoustic doppler current profilers have transformed water movement measurement by capturing data at multiple depths simultaneously, not just at a single point. These sophisticated instruments,