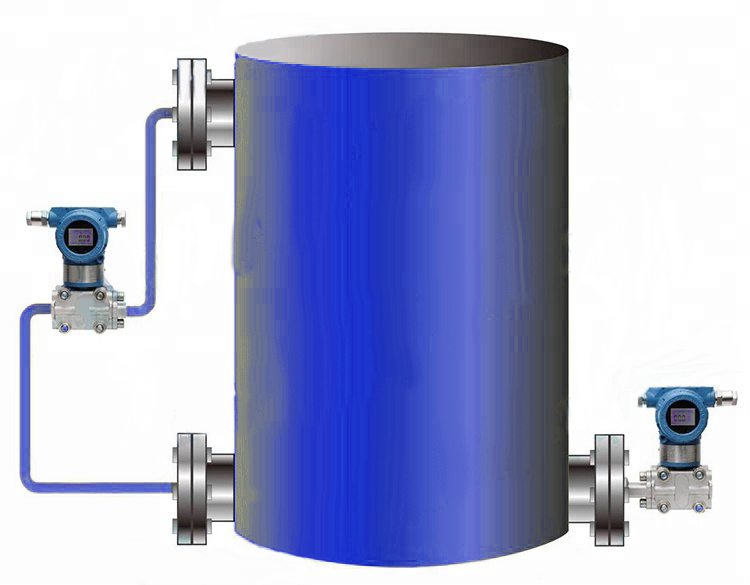

the characteristics of open tanks Single flange differential pressure transmitter

Differential pressure single flange level gauge_Single flange differential pressure transmitter to measure the characteristics of open tanks

① The working pressure of the remote pressure transmitter also depends on the specification of the selected flange.

② The working temperature of the remote device is determined by the type of filling fluid selected.

③ The remote transmission pressure transmitter refers to the output change caused by the temperature action of the remote transmission device on one side.

④ The effects of static pressure and temperature are measured at large scales.

⑤ The length of the capillary tube on one side of the GP type remote pressure transmitter is generally 1.5 meters, and the length should not exceed 3 meters (negotiated in special circumstances)

8 attentions for single flange differential pressure transmitter measure the liquid level of an open tank

Micro Differential Pressure Single Flange Level Gauge_Single Flange Differential Pressure Transmitter Measuring Open Tank Features Pay attention to the following conditions:

1. When measuring the liquid pressure, the installation position of the flange liquid level transmitter should avoid the impact of the liquid (that is, the water hammer phenomenon) to avoid overpressure damage to the sensor.

2. When the single-flange liquid level transmitter freezes in winter, it is necessary to take anti-freezing measures according to the transmitter installed outdoors, so as to avoid the expansion of the liquid in the pressure port due to the freezing volume, which will lead to damage to the sensor.

3. When wiring, pass the cable through the waterproof connector (accessory) or coiled tube and tighten the sealing nut to prevent rainwater from leaking into the transmitter housing through the cable.

4. When the single-flange liquid level transmitter measures the liquid pressure, the pressure tap should be opened on the side of the process pipeline to avoid sedimentation and accumulation of slag.

5. It is necessary to prevent the flange liquid transmitter from contacting with corrosive or overheated media, and also to prevent dross from depositing in the conduit;

6. When measuring the pressure of gas, the pressure tap should be opened at the top of the process pipeline, and the flanged liquid level transmitter should also be installed on the upper part of the process pipeline so that the deposited liquid can be quickly injected into the process pipeline.

7. For the single-flange liquid level transmitter, it should be noted that the pressure guiding pipe of the sensor should be installed in a place with small temperature fluctuation;

8. When measuring steam or other high-temperature media with a single-flange liquid level transmitter, it is necessary to add a buffer tube (coil) and other condensers, and the working temperature of the transmitter should not exceed the limit.