An electronic pressure switch is a device that uses an electronic pressure sensor to open or close a switch contact when a preset pressure is reached. It is commonly used in machine building and various industrial applications for tasks such as pressure monitoring, control, and high/low alarms. Electronic pressure switches offer several advantages, including a digital display for pressure readings, adjustable switch points, and higher reliability. They combine the functionalities of an electronic switch, pressure sensor, and digital indicator in a single instrument. These switches can be programmed in the field, have features like local display and programmable timers, and provide a longer lifespan compared to mechanical switches [3]. When selecting an electronic pressure switch, factors such as the enclosure material and weather-proof rating should be considered.

Electronic pressure switch installation instruction #

! Make sure the system is under no pressure before installing and removing

the sensor.

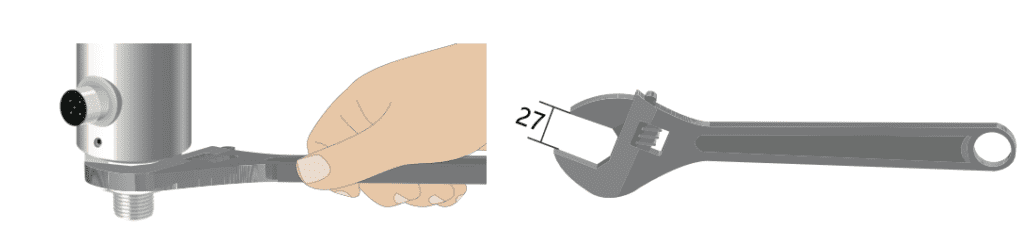

- Connect the sensor device to the optional process interface

- Tightening torque range recommended: 25 to 35Nm

- In critical applications (such as severe shock or shock), pressure pipe

- connections Mechanical decoupling can be achieved through

- miniature hoses.

Electronic pressure switch fault code and handling #

| EREP | EEPROM data check error, mainly in the boot read data detection. Manual viewing is required, and the error can be restored by resetting. |

| ERo1 | Switch 1 output short circuit. Error output turned off and out of control. Measure: eliminate short circuit and power up again |

| Ero2 | Switch 2 output short circuit. Error output turned off and out of control. Measure: eliminate short circuit and power up again |

| ER12 | Switch 1/2 output shorted simultaneously. Error output turned off and out of control. Measure: eliminate short circuit and power up again. |