Set parameters in transmitter #

Set parameters from M10 to M14 according to actual pipe parameters at worksite.

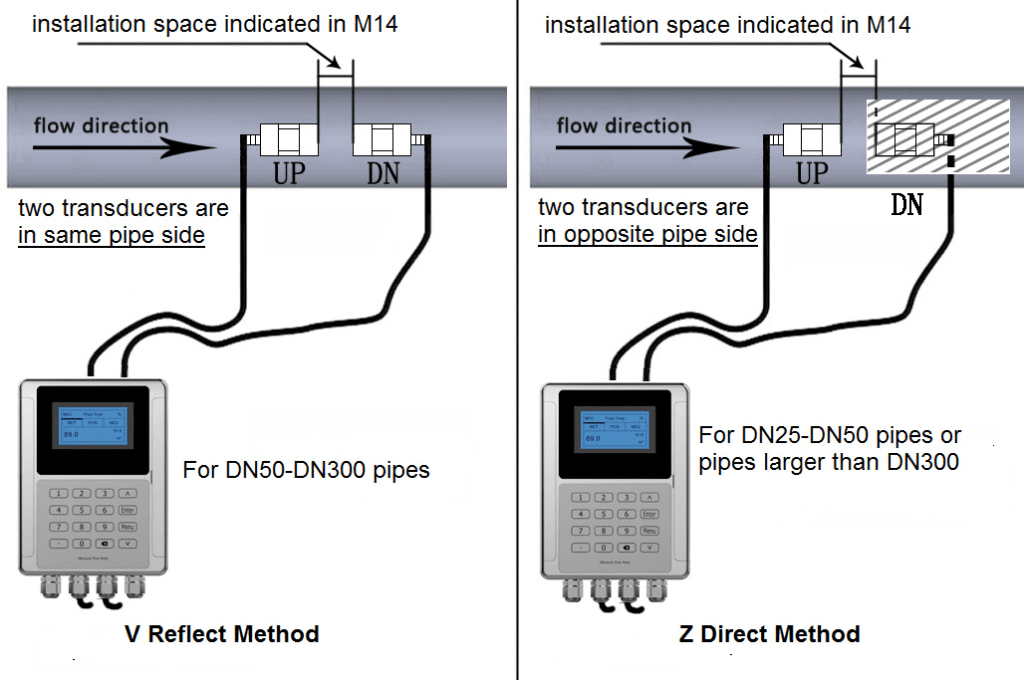

When selecting transducer mounting method in M13, please note that for DN50-DN300 pipes, ‘0.V reflect method’ should be the first choice; for DN25-DN50 or pipes larger than DN300, ‘1.Z direct method’ should be the first choice.

After setting parameters in above menus, M14 will automatically indicate an installation space between two transducers. Please remember this value.

Install the transducers #

Install two transducers according to mounting method selected in M13 and according to installation space indicated in M14. You can first install and fasten one of the transducers, then move slightly one of the other transducers to get good result.

Please note that:

(1). Select a position where it is always full of liquids.

(2). Select a position where there is enough straight length.

Transducers’ installation point should be far from pump, valve or bent to assure liquid’s flow in pipe is steady. Generally, make sure there is at least 10D straight pipe length (D means diameter) in upstream direction and at least 5D in downstream direction.

(3). If there is paint or rust on pipe surface, please polish pipe surface until you can see metallic luster.

(4). Please apply adequate coupling compound to transducers’ bottom.

(5). On horizontal pipes, the transducers should be mounted in the 3 o’clock and 9 o’clock positions of the pipe section to avoid air bubbles inside the top portion of the pipe. Two transducers should be in same side with V installation method, while they should be in opposite sides with Z method.

(6). At last, transducers should be fastened tightly by using the clamp fixtures we offered with products.

Check if installation is correct #

Please always remember to check M04 value during process of installing transducers.

(1). Both UP and DN signal strength values should be bigger than 75 .

(2). Q (Quality) value should be bigger than 75 too.

(3). If installation is correct, the transit time ratio should be 100±3%. (If it is not in this range, it means installation space between transducers should be adjusted slightly.)

If All above required value can be met, then it means installation is successful.