- Tel: +86 28 87436908

- Email: info@cdsentec.com

The building materials industry utilizes sensors for various applications to enhance efficiency and optimize operations. Sensors are used to track materials through the supply chain, allowing companies to monitor their movement in real-time.

Building materials production is a vital aspect of the building construction industry. It involves the manufacturing and processing of raw materials into finished products used in construction projects. The production of building materials encompasses various stages, from sourcing the raw materials to the final manufacturing process.

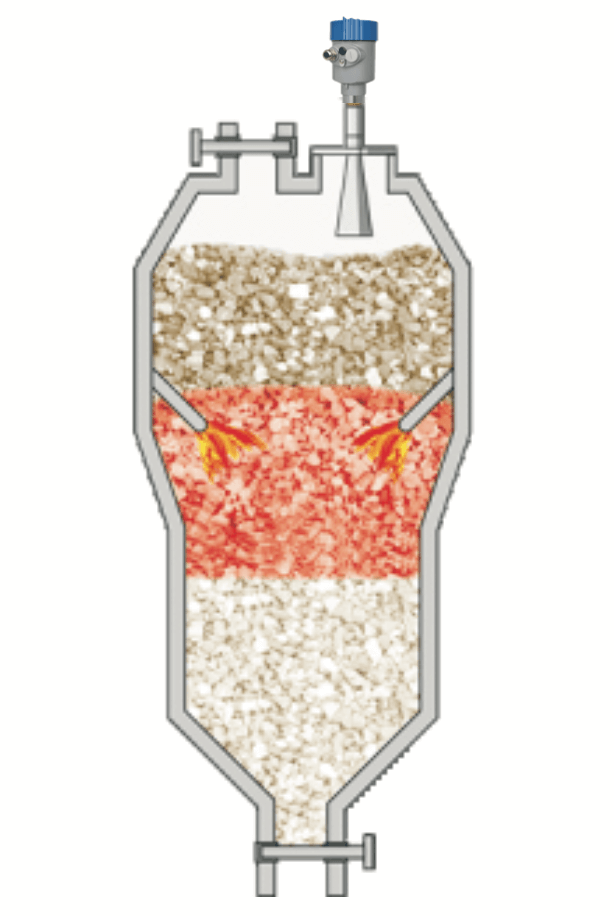

A lime kiln is used to produce quicklime through the calcination of limestone. Here the furnace is filled from the top and the calcined limestone (quicklime) is collected at the bottom of the furnace. Accurate level measurement ensures optimal charging and hence efficient operation of the furnace.

Materials such as concrete and mortar are needed in widely different compositions depending on the application. The various raw materials are stored in segmented towers, which then blend cement, lime and other aggregates according to specific requirements. In each individual segment, reliable level measurement and point level detection ensure the constant availability of the raw materials and cost-effective operation of the plant.

In the persistent processing process, hard rock is broken into transportable stones by blasting. Further processing into basic building materials such as crushed stone, pebbles or sand requires further processing steps. Jaw crushers and roll crushers break large rocks into different particle sizes. In order to ensure the economy of operation and minimize the wear of the crusher, the material level and limit of the crusher must be monitored

In building materials production, various types of level sensors are used to ensure quality control and efficiency. These sensors enable automation, precise control, and consistent product quality in building materials production. They help monitor and optimize various parameters, ensuring that the production process meets the required standards and specifications.

In building materials storage, level sensors are crucial for ensuring proper control and efficiency. These sensors are used to measure and monitor the level of various substances in containers or storage tanks, such as liquids or granular materials.

To ensure continuous production, even if material production is interrupted, the raw materials are stored in large bunkers with heights of over 30 m and diameters of up to 20 m. The large dimensions of the silos require the filling and emptying to take place at multiple points. Uniform filling and emptying of the bunkers is achieved through level and pressure measurement at various points in the bunker.

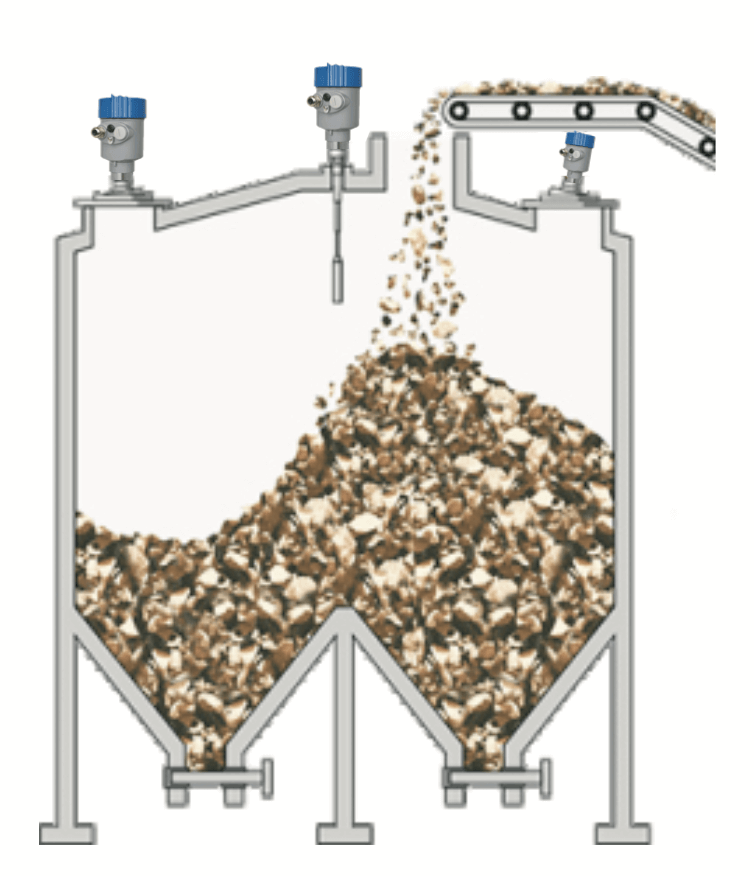

After crushing and screening, the different aggregates are transported via conveyor belts and distributed among the silos. Before further processing, the stones, gravel or rock flour are stored in buffer and production silos. To ensure optimal material storage, a precise level measurement is required.

Different qualities are required from the asphalt depending on the usage and climatic conditions, so every asphalt mixture varies depending on the application. Asphalt is always extremely viscous, hot and highly adhesive. Due to these properties and the numerous different asphalt mixtures, reliable level measurement and point level detection methods are essential.

In a hydroelectric power plant, water is conveyed from the dam to the turbines through penstocks. A partial or complete rupture of a pressure line can increase the flow in the line beyond the maximum flow. If the leak goes undetected, it can cause floods and destroy power plants, resulting in lost production. Therefore, it is important to measure the flow reliably in order to detect if there is a rupture in the pipeline and then take the necessary action, such as closing the pressure valve.

In building materials storage, various types of pressure and level sensors are used to monitor and control different aspects of the storage process. These sensors enable precise control, automation, and monitoring of the storage process, ensuring that the materials are stored in optimal conditions and meet the required standards and specifications.

Building materials transportation plays a crucial role in the construction industry. Efficient and timely transportation of materials is essential to ensure smooth and uninterrupted construction operations.

The transport of coarse and fine bulk solids within a stone processing facility takes place in most cases via conveyor belts. To achieve an even throughput and compensate for volume fluctuations during transport, belt transfer points are integrated in the conveyor line. The incoming bulk material is briefly stored in a buffer silo to prevent belt overfilling. This is the point where the level and the point level must be monitored.

Dust-free, closed loading systems are needed for fine aggregates and finished products such as cement. Automated loading of trucks is preferred in the industry and, while the load quantity is determined with a weighing system, it must be ensured that the truck is in the correct place and not overfilled. Reliable point level detection and vehicle positioning shortens loading times, increases throughput and improves the efficiency of the entire system.

To efficiently process construction materials such as mortar, mortar or plaster, they are transported directly to the construction site in transport silos. Add water to building materials on site as needed and stir to combine immediately. Make sure there is enough material in the silo by measuring the level.

Various types of pressure, level, flow sensors are used in building materials transportation to ensure efficiency, safety, and optimal conditions.These sensors enable precise control, automation, and monitoring of the transportation process, ensuring optimal conditions and compliance with standards.

SenTec online resource library is a place you can know more knowledge from video, cases study, e-book etc.