Ultrasonic flow meters are instruments that measure flow by detecting the effect of fluid flow on an ultrasonic beam (or ultrasonic pulse). There are most common two types of ultrasonic flowmeter technology: Doppler frequency shift ultrasonic flowmeter and transit time ultrasonic flow meter.

What is the difference between the doppler ultrasonic flowmeter and transit time ultrasonic flowmeter ?

According to the principle of signal detection, ultrasonic flowmeter can be divided into propagation velocity difference method (direct time difference method, time difference method, phase difference method and frequency difference method), beam shifting method, Doppler method, cross-correlation method, spatial filtering method and noise law.

Ultrasonic flowmeters are generally used in projects that need to know pipeline flow data. There are two options. Doppler is suitable for open channel, multi-impurity, and multi-bubble liquid measurement, and is usually not suitable for very clean liquids. The time difference method is suitable for the measurement of a small amount of impurities and relatively pure liquid in a full pipeline.

Transit time Ultrasonic flow meter working principle

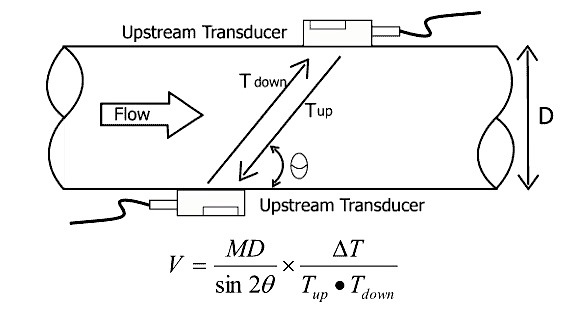

When the ultrasonic beam propagates in the liquid, the flow of the liquid will cause a small change in the propagation time, and the change of the propagation time is proportional to the flow rate of the liquid, and the relationship is in accordance with the following expression

θ is the angle between the sound beam and the liquid flow direction

M is the number of straight-line propagation of the sound beam in the liquid

D is the inner diameter of the pipe

Tup is the propagation time of the sound beam in the positive direction

Tdown is the propagation time of the sound beam in the opposite direction

ΔT=Tup –Tdown

Suppose the speed of sound in the static fluid is c, the speed of fluid flow is u, and the propagation distance is L. When the sound wave is in the same direction as the fluid flow (that is, the direction of the flow), its propagation speed is c+u; otherwise, the propagation speed is cu .Place two sets of ultrasonic generators and receivers (T1, R1) and (T2, R2) at two places separated by L. When T1 transmits ultrasonic waves in the forward direction and T2 in the opposite direction, the time required for the ultrasonic waves to reach the receivers R1 and R2 respectively is t1 and t2, then

t1=L/(c+u); t2=L/(c-u)

Since in the industrial pipeline, the flow velocity of the fluid is much smaller than the speed of sound, that is, c>>u, so the time difference between the two is ▽t=t2-t1=2Lu/cc It can be seen that when the propagation speed of the sound wave in the fluid is c When known, as long as the time difference ▽t is measured, the flow velocity u can be obtained, and then the flow rate Q can be obtained. The method of measuring flow using this principle is called the time difference method ultrasonic flowmeter.

What is the advantages and disadvantages of the transit time ultrasonic flowmeter ?

1.Advantage: Ultrasonic flowmeter is a non-contact instrument, which can measure the flow of medium with large diameter and can also be used for the measurement of medium that is not easy to contact and observe. Its measurement accuracy is very high, and the external clip-type installation can reach the highest accuracy of ±0.5%. It is almost not disturbed by various parameters of the measured medium, especially it can solve the strong corrosiveness, non-conductivity, Flow measurement of radioactive and flammable and explosive media.

2. Disadvantages:The shortcomings of ultrasonic flowmeters are mainly that the temperature range of the measurable fluid is limited by the temperature resistance of the ultrasonic transducer aluminum and the coupling material between the transducer and the pipeline, and the original data of the sound transmission speed of the measured fluid at high temperature is incomplete. . Currently it can only be used to measure fluids below 200°C.

types of transit time ultrasonic flowmeters

*Plug-in ultrasonic flowmeter: can be installed and maintained without production. The ceramic sensor is used for non-stop installation using a dedicated drilling device. Generally, it is a single-channel measurement. In order to improve the measurement accuracy, multi-channel can be selected.

*Segment type ultrasonic flowmeter: It is necessary to cut the pipeline to install, but the production can not be stopped for future maintenance. Mono or multi-channel transducers can be selected.

*Clamp-on ultrasonic flowmeter: It can complete fixed and mobile measurement. Use special coupling agent (room temperature curing silicone rubber or high temperature long-chain polymer grease) to install, and the pipeline will not be damaged during installation.

*Portable ultrasonic flowmeter: portable use, built-in rechargeable lithium battery, suitable for mobile measurement, with magnetic sensor.

*Handheld ultrasonic flowmeter: small size, light weight, built-in rechargeable lithium battery, hand-held use, with magnetic sensor.

*Explosion-proof ultrasonic flowmeter: used for liquid flow measurement in explosive environments, it is explosion-proof and intrinsically safe. That is, the converter is explosion-proof and the sensor is intrinsically safe.

transit time Ultrasonic Flow Meter Applications

The external clamp or pipe segment ultrasonic flow meter is based on the principle of “velocity difference method” to measure the liquid flow in the circular tube. It adopts advanced multi-pulse technology, signal digital processing technology and error correction technology, which makes the flow meter more suitable for the environment of the industrial site, and the measurement is more convenient, economical and accurate. The products have reached the advanced level at home and abroad, and can be widely used in petroleum, chemical, metallurgy, electric power, water supply and drainage and other fields.

transit time Ultrasonic Flow Meter Installation

The measurement line accuracy of the time difference ultrasonic flowmeter is higher than 1.0%. Due to the diversity of the industrial site, especially the surrounding environment of the pipeline, how to install and debug the ultrasonic flowmeter according to the specific environment? How to Choose ultrasonic flow sensor installation points ?

Proper installation point is a key for transducer installation. Following factors must be considered: Full filled pipeline, shaking, steady flow, scaling, temperature, pressure, EMI, instrument well.

>> Full filled pipeline

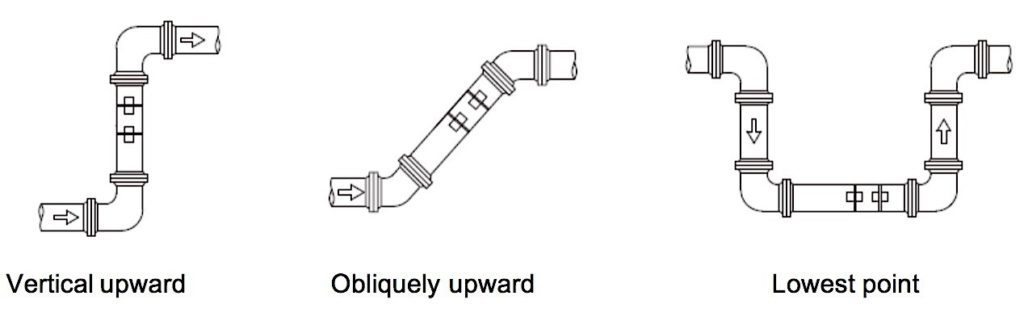

Following situations can be full filled of liquid:

>> Shaking

There cannot be obvious shaking on the installation point, otherwise it needs to be tightened.

>>Steady flow

Steady flow is helpful for ensuring measurement accuracy.

Standard requests for steady flow are:

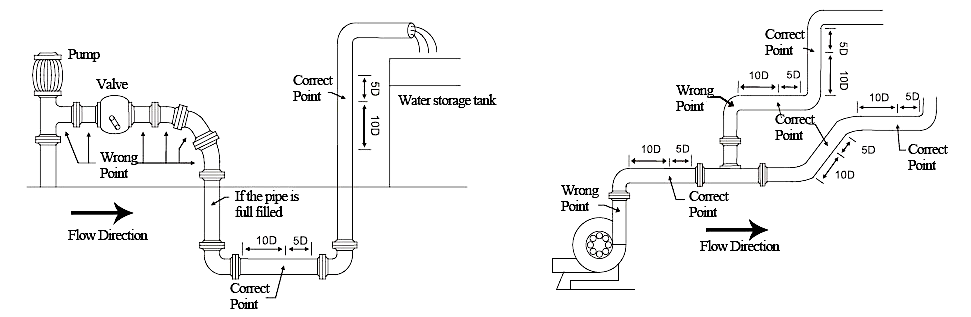

1. The pipe should be far away from pump outlet and half-open valve.

10D to upstream and 50D to downstream. (D means outer diameter)

2. 30D to pump outlet and half-open valve.

>> Scaling

The inside scaling would have bad effect on ultrasonic signal transmission, and would decrease the inner diameter as well. As a result, the measurement accuracy can not be guaranteed. Please try to avoid choosing the installation point with inside scaling.

>>Temperature

The liquid temperature on installation point should be in the working range of transducers. Please try to choose the point with lower temperature. Avoid to choose points like the outlet of boiler water and heat exchanger. Return water pipe would be better.

Temperature range of standard clamp on and insertion transducers: -30 ~ 90℃

Temperature range of high temperature clamp on and insertion transducers: -30 ~ 160℃

>>Pressure

The maximum pressure for standard insertion and inline transducer is 1.6MPa

Out of this range need customized.

>>EMI (electromagnetic interference)

The ultrasonic flow meter, transducer and signal cable can be easily interfered by interference sources such as frequency changer, radio station, microwave station, GSM base station and high-tension cable. Please try to avoid these interference sources when choosing installation points.

The shield layer of flow meter, transducer and signal cable should be connected to earth.

Better to use isolated power supply. Do not use the same power supply with the frequency converter.

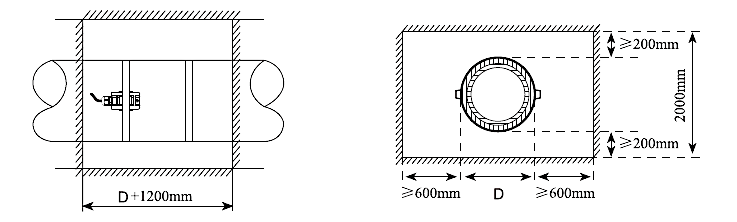

>>Instrument well

When measuring underground pipes or need to protect the measuring points, an instrument well is required. To ensure the enough installation space, the sizes of instrument well should meet the following requirements.

※Note: As one of the earliest flow meter manufacturer, SenTec provide a wide variety flow measurement solutions, such as differential pressure flow meters, Calorimetric Flowmeter, liquid flow sensor, Ultrasonic Level Transmitter, mass flow meter, Variable Area Flowmeter or Rotameter, Electromagnetic Flowmeter, Turbine Flowmeter, Vortex Flow Meter, Thermal Flowmeter, Coriolis Flowmeter, Mass Flowmeters, Open Channel Flowmeters etc.

For specific ultrasonic Flowmeter price, please contact our sales engineer.