Here’s a breakdown of how mechanical (traditional) anemometers stack up against ultrasonic anemometers, and why you might pick one over the other:

1. Traditional Anemometers (Cup, Vane, or Propeller Types)

How they work:

- Cup anemometers: Wind spins cups mounted on a vertical axis.

- Wind vanes: A physical arrow points into the wind to indicate direction.

- Propeller anemometers: Blades rotate horizontally to measure speed.

Pros:

- Lower upfront cost: Simple design makes them cheaper to manufacture.

- Proven reliability: Decades of use in basic weather monitoring.

- Easy to calibrate: Mechanical systems are straightforward to adjust.

- No power needed: Some mechanical models work passively (e.g., wind vanes).

Cons:

- Moving parts = wear and tear: Cups, bearings, or propellers degrade over time, requiring frequent maintenance.

- Vulnerable to environmental damage: Ice, dust, or debris can jam mechanisms.

- Slower response time: Mechanical inertia delays real-time wind measurement.

- Limited directional accuracy: Wind vanes struggle in turbulent or low-wind conditions.

- Freezing risks: Ice buildup halts operation in cold climates.

Best for: Budget-friendly setups, non-critical applications, or environments with stable, mild weather.

2. Ultrasonic Anemometers

How they work:

- Uses ultrasonic pulses between sensors to calculate wind speed/direction based on time-of-flight differences.

- No moving parts—relies entirely on sound waves.

Pros:

- Zero mechanical wear: No cups, blades, or bearings to replace.

- High precision: Measures 3D wind vectors (speed + direction) with millisecond updates.

- All-weather durability: Resists ice, dust, sand, and heavy rain (no parts to freeze or clog).

- Low maintenance: Occasional cleaning and calibration suffice.

- Silent operation: Ideal for noise-sensitive areas (e.g., wildlife reserves).

- Compact design: Easy to install in tight spaces or mobile setups.

Cons:

- Higher upfront cost: Advanced electronics and sensors drive up initial investment.

- Power dependency: Requires continuous electricity (solar/battery solutions add complexity).

- Calibration sensitivity: Temperature fluctuations or sensor misalignment can affect accuracy.

- Limited range in extreme conditions: Heavy rain or fog may slightly disrupt ultrasonic signals.

Best for: Critical applications (aviation, renewables), harsh environments, or where precision and reliability are non-negotiable.

Head-to-Head Comparison

| Factor | Traditional Anemometers | Ultrasonic Anemometers |

|---|---|---|

| Cost | Low upfront cost, high long-term maintenance | High upfront cost, minimal maintenance |

| Accuracy | Moderate (degrades with wear) | High (stable over time) |

| Response Time | Slow (mechanical lag) | Instantaneous (real-time updates) |

| Durability | Prone to ice/dust damage | Rugged; handles extreme temps, storms, and dirt |

| Installation | Simple, but requires sturdy mounting | Flexible, but needs precise alignment |

| Environmental Fit | Mild climates, low wind variability | Harsh climates, high-precision needs |

| Maintenance | Frequent cleaning, lubrication, part replacement | Rare calibration, occasional cleaning |

When to Choose Which?

- Pick traditional anemometers if:

- You’re on a tight budget.

- The environment is mild (no ice/storms).

- Slight data delays are acceptable (e.g., basic weather stations).

- Go ultrasonic if:

- You need bulletproof reliability (e.g., airports, wind farms).

- Maintenance access is limited (e.g., remote sites).

- Precision is critical (e.g., climate research, disaster monitoring).

Sentec Ultrasonic Anemometers

Hey there! At Sentec, we’ve got both traditional and ultrasonic wind sensors covered—but let’s be real, our ultrasonic models are where we shine.

- Zero Maintenance: Seriously, No moving parts = no breakdowns. Set it and forget it!

- Lightweight & Compact: Our aluminum/plastic shells make them easy to haul up towers, rooftops, or remote sites.

- Pinpoint Accuracy: Measures wind speed and direction in 3D, even in a light breeze. Perfect for picky jobs like wind farms or airport safety.

Customized Ultrasonic Anemometers for Diverse Application Scenarios

At Sentec, we specialize in designing and manufacturing ultrasonic wind speed and direction sensors tailored to meet the unique demands of your operational environment. Our expertise lies in delivering bespoke solutions that align with application-specific requirements.

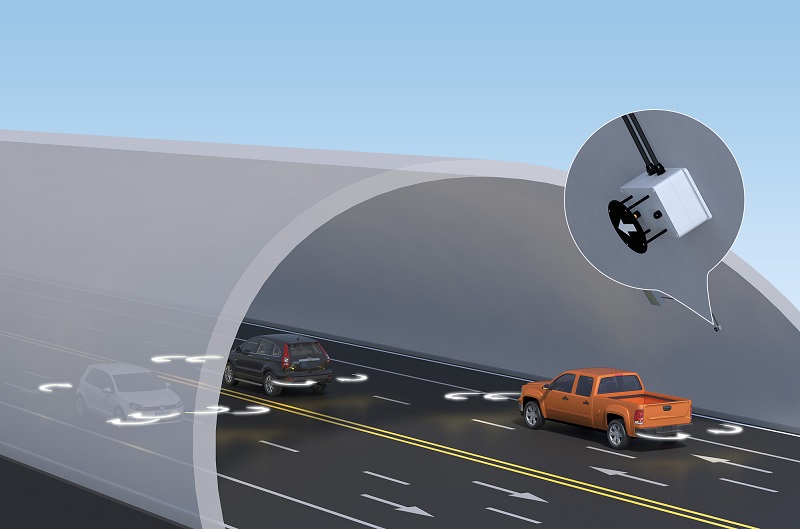

Tunnel anemometer

The tunnel-specific detection probe is installed on the tunnel wall to provide real-time measurements of wind speed and direction inside the tunnel to the central control room. These values serve as the fundamental basis for ventilation system adjustments and operational management

The detector enables on-site real-time monitoring of operational status and detection data. Its data output interface transmits analog and switch signals to a local PLC in nearby substations. These signals are then relayed to the central control room via data optical transceivers and fiber optic cables.

Ultrasonic anemometer for UAV

This compact ultrasonic anemometer is specifically engineered for integration with small aerial vehicles and unmanned platforms to monitor low-altitude wind speed and directional data. Weighing only 56g with a 50mm diameter, it represents one of the lightest and smallest ultrasonic wind sensors available commercially. The device features a ruggedized enclosure with exceptional electromagnetic interference resistance (IP65-rated for dust/water protection) and operational stability across extreme conditions: -40°C to +70°C ambient temperatures and altitudes up to 4,000m.

More application scenarios?

We’re here to help.