Flow meters play a crucial role in various industries that require the measurement of liquid or gas flow rates. There are several types of flow meters available in the market, but one that stands out is the Coriolis flow meter. In this article, we will delve into the functionality and benefits of Coriolis flow meters and explore their applications in different industries.

Introduction to Coriolis flow meters

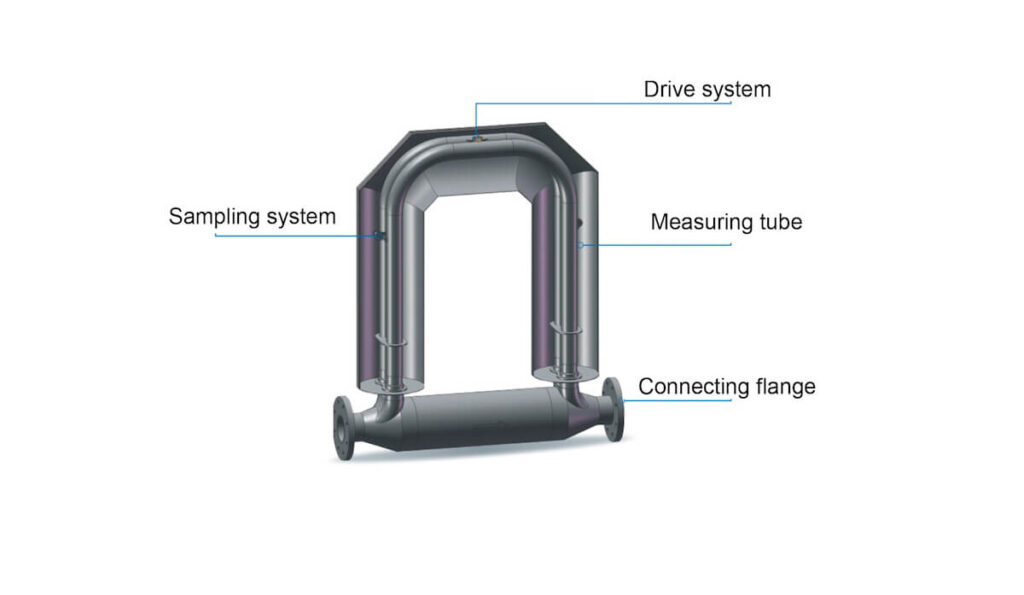

Coriolis flow meters are devices that measure the mass flow rate of liquids or gases. They are based on the Coriolis principle, which states that a mass moving in a rotating system experiences a force that is perpendicular to its direction of motion and to the axis of rotation. The Coriolis flow meter consists of a U-shaped tube that is oscillated at a specific frequency. As the fluid flows through the tube, it causes a change in the oscillation frequency, which is directly proportional to the mass flow rate.

How do Coriolis flow meters work?

Coriolis flow meters work based on the principle of the Coriolis effect. When a fluid flows through the U-shaped tube of the flow meter, it causes the tube to twist and oscillate. The oscillation frequency is measured by two sensors located at the inlet and outlet of the tube. The difference in the oscillation frequency is proportional to the mass flow rate of the fluid. The flow meter can also measure the density and temperature of the fluid, which can be used to calculate the volumetric flow rate.

Understanding the flow meter coriolis principle

At the time, Coriolis discovered the Coriolis force flow meter while studying the water turbine. Coriolis force refers to the force exerted on the wall of the pipe by the fluid flowing in the rotating pipe. The mass flowmeter is based on the Coriolis force. There are two parallel T-shaped vibration tubes inside the sensor, a driving coil is installed in the middle, and a vibration pickup coil is installed at both ends. When the excitation voltage provided by the transmitter is applied to the driving coil , the vibrating tube vibrates in a reciprocating cycle.

The fluid medium in the industrial process flows through the vibrating tube of the sensor, which will produce a Coriolis force effect on the vibrating tube, causing the two vibrating tubes to vibrate torsionally. The vibration pickup coils installed at both ends of the vibrating tube will Two sets of signals are produced that are out of phase, and the difference between the two signals is proportional to the mass flow of fluid through the sensor. The computer calculates the mass flow through the vibrating tube. When different media flow through the sensor, the main vibration frequency of the vibrating tube is different, and the density of the medium is calculated accordingly.

Advantages of using Coriolis flow meters

Coriolis flow meters offer several advantages over other types of flow meters. One of the main advantages is their accuracy. Coriolis flow meters can measure mass flow rates with an accuracy of up to 0.1%. They are also insensitive to changes in the fluid’s viscosity, density, and temperature. Coriolis flow meters can operate in extreme conditions, such as high pressures and temperatures, and are resistant to corrosion and wear. They are also low maintenance and have a long lifespan.

Factors to consider when selecting a Coriolis flow meter

Several factors need to be considered when selecting a Coriolis flow meter. These include the fluid properties, such as viscosity, density, and temperature, the flow rate range, the required accuracy, the installation requirements, such as the available space and orientation, and the cost. It is essential to select a flow meter that is suitable for the specific application and can provide accurate and reliable measurements.

5 tips for Coriolis flow meter installation

- Entrained air bubbles: When the mass flowmeter measures liquid, when the content of the mist-like gas exceeds 1%~5% of the volume content, the mass flowmeter will stop working. Vibration to eliminate the gas before it reaches the sensor, if this is not possible, minimize the gas content. When the pressure of the liquid is lower than its vapor pressure, bubbles will be generated, caused by the geometry of the flow tube and the flow of the liquid. The pressure drop at the ends can reduce the effective pressure of the liquid below its vapor pressure, and the gas in the liquid in the pipe can have the same effect on the sensor as a mist bubble. Once the sensor is sized, the back pressure required to maintain the liquid state can be calculated. Install the sensor in a location that can meet the required back pressure.

- Sediments and suspended solids: The mass flow meter can calculate the mass content of one component in a two-component solution or slurry. An accurate density measurement must avoid situations where sediment adheres to the wall of the measuring tube or Solid particles settle out of suspension (flow rate too low).

- Installation direction: The installation direction depends on the application. Some mass flow meters with geometric shapes will gather some solid or gaseous substances in a certain installation direction. If a vertical installation is necessary and the fluid flows from top to bottom, measures must be taken to ensure that gas cannot enter the sensor from the sensor inlet pipe. Side mounting (one flow tube over the other) is not recommended except in special cases.

- Support: Excessive mechanical stress during sensor installation will affect the zero point of the mass flowmeter. If these stresses are constantly changing, the meter will exhibit unacceptable zero point drift. The sensor shall be supported by the piping system. Flanges should be concentric to avoid compression, bending or twisting. Pipe supports should be as close as possible to the inlet and outlet flanges, and these supports should be attached to a common structure.

- Vibration. The introduction of the double-pipe design greatly reduces but does not completely eliminate the effect of common mode vibration on the mass flow meter. External vibrations introduced by the pipeline system can cause undesired vibration patterns of the sensor. If the external vibration frequency is equal to or close to the frequency of the sensor drive system, it will interfere with the drive control system of the instrument, causing the flow tube to vibrate unstable or stop vibration.

During use, attention should be paid to changes in operating conditions or environmental conditions, and the zero point should be checked or adjusted to eliminate drift. Whether a certain type of mass flow meter can measure the gas flow depends on whether the specified mass flow value can be achieved. Due to the low density of the gas, it must be achieved at very high pressures and very high flow rates. In addition, attention should be paid to the effect of medium density. In practical application, the manufacturer should be consulted to find a reasonable solution.

Faults and Treatment Methods of Coriolis flow meter

During the use of the mass flowmeter, some minor faults are often caused by operating errors. The following is an answer to some common mass flowmeter faults and solutions.

Hardware malfunction

If the error is too large, the display of the totalizer is not bright or does not increase in value, the display is blank, etc. The reasons are:

1. Improper installation can directly lead to zero drift of the flowmeter. For example, if the mass flowmeter is installed close to the pump outlet, the sensor support strength is not enough, the improper welding of the connecting flange generates stress signals, and the cable is subject to electromagnetic interference.

2. Wiring problems If the display does not light up, check the power supply connection of the totalizer. If the fuse is burned, confirm whether the input voltage is consistent with the nominal value of the standard voltage and whether the AC and DC forms are consistent. If the totalizer does not increase with the flow rate, check the totalizer wiring. If the totalizer is equipped with a forward/reverse program, check the flowmeter wiring. Because the flowmeter wiring is incorrect, the totalizer will be reversed. Does not increment when flowing.

3. If the process medium changes, if the measurement medium has phenomena such as air inclusion, gasification or two-phase flow, the transmitter will display an alarm display. In severe cases, the sensor will stop working.

4. Transmitter failure.

5. Sensor failure.

6. Pipe purging problems.

Software problem

Troubleshooting of mass flowmeter – for the flowmeter that has just been calibrated, be sure to pay attention to the zero-point calibration under the current working conditions before installing and using it. It must be ensured that the flowmeter is filled with medium and the stop valves at both ends are closed before zero-point calibration. There are many methods, such as panel operation, hand communicator and using prolink II software.

1. The zero point calibration is wrong.

2. The parameter settings are incorrect.

3. Pulse fluctuations of the power supply.

4. The configuration is wrong (be sure to pay attention to the range).

5. The operation is wrong.

Conclusion

Coriolis flow meters are essential devices that provide accurate and reliable flow measurement for various industries. They are based on the Coriolis principle, which states that a mass moving in a rotating system experiences a force that is perpendicular to its direction of motion and to the axis of rotation. Coriolis flow meters offer several advantages over other types of flow meters, such as high accuracy, resistance to changes in viscosity and temperature, and low maintenance. It is essential to select the right flow meter and carefully install them for the specific application and perform periodic calibration to ensure accurate and reliable measurements.

SenTec as a leading coriolis flow meter manufacturers win lots of accumulated successes projects worldwide. Contact us to learn more.