How to identify the direction of fluid flow in the pipeline #

After the sensor and wiring are correctly installed, the instantaneous flow rate display value is positive, indicating that the direction of the fluid is positive, that is, from the upstream probe to the downstream probe. If the instantaneous flow rate is displayed as a negative value, it means that the flow rate is in the opposite direction.

How to use zero point cut to avoid invalid accumulation #

The data in the window 41 is called the low flow rate cutoff value, and the system treats the flow whose absolute value of the flow rate is lower than this value as “0”. This parameter can be set in this way to avoid false accumulation of the measurement error generated by the flowmeter when the real flow is “0”. -Under normal circumstances, set this parameter to 0.03m/s. When the flow rate is greater than the low flow rate cutoff value, the low flow rate cutoff value has nothing to do with the measurement result and will never affect the measurement result.

How to set the zero point #

When the pipeline is full of still water and the instantaneous flow rate displayed by the flowmeter is not zero, use the M42 menu to adjust the zero. Do not perform any operations during the zero-clearing process. After zero adjustment, use M.2 menu to store the zero point.

how to modify the meter coefficient (scale factor) for calibration and correction. #

When the flowmeter runs for too long, it may cause errors in the flowmeter. At this time, one of ours is corrected by modifying the coefficient (scale factor), and the true value is displayed in the M45 window. The ratio of the measured value is can. The meter coefficient must be entered according to the actual calibration result.

How to use 4~20mA current loop output #

Ultrasonic flowmeter/heat meter with a current loop output accuracy is better than 0.1%, and can be set to 4-20mA and 0-20mA and other output modes, use window M55 to select.

Input the flow value represented by 4mA in window M56, and input the flow value represented by 20mA in window M57. If you consider the flow direction, you can choose to use the 0~4~20mA output mode. When the flow direction is negative, the output current is within the range of 0~4mA. When the flow direction is positive, the output current is within the range of 4~20mA. Select in window M55, and use window M58 to force the current loop to output a value to verify its accuracy. For the wiring diagram, please refer to page 4 “Host Installation and Wiring Diagram”.

How to output accumulated pulse #

Ultrasonic flowmeter/heat meter series Ultrasonic flowmeter/heat meter each flow through-a unit flow rate, can produce a cumulative pulse.

The accumulated pulse can only be output through hardware OCT or relay. Therefore, the hardware OCT or relay must be set accordingly (see window M78, M79).

For example, if you want to use the relay to output positive cumulative pulses, each pulse represents a flow of 0.1m, you can set the following:

①Select the cumulative flow unit in the window OM32: “cubic meter (m3)”;

②Select the multiplication factor in window M33: “2. x0.1”;

③Select in window M79: “9. Positive cumulative pulse output”.

Note: The cumulative pulse size should be selected appropriately. If it is too large, the output period will be too long; if it is too small, the relay will act too frequently, affecting its service life, and if it is too fast, it will cause the error of missing pulses. It is recommended to use a rate of 1~60 pulses/minute.

Do not use the OCT output The OCT output of the ultrasonic flowmeter/heat meter is an electrically isolated open collector output, which can work at DC60V100mA. By setting M78, you can set the conditions for turning it on. For the wiring diagram, please refer to “Host Installation and Wiring Diagram” on page 4

How to use relay output #

The relay output of the ultrasonic flowmeter/heat meter can work AC125V/DC28V1A, and the opening conditions can be set by setting M78. For the wiring diagram, please refer to page 4 “Host Installation and Wiring Diagram”.

How to use quantitative (batch) controller #

The flow meter/heat meter has a built-in batch controller, which can quantitatively control the flow. Use the keyboard or the rising or falling edge of the analog input signal as the input for control, and the output can use OCT or relay. When using analog input as a control signal, input a current signal greater than 2 mA at the analog input terminal indicates the “1” state, and 0 mA current indicates the “0” state.

Use window M80 to select the control input signal, use window M78 (OCT output) or M79 (relay output), select item 8 “as a quantifier output”, and an output signal will be generated on the OCT or relay output.

The quantitative value is input in window M81. After entering the quantitative value, the batch controller is started.

The calibration result is temporarily stored in the RAM of the host’s own power-down protection. Need to use the “1” option of the M26 menu can be stored in the internal FLASH to achieve the purpose of permanent memory. After doing this, the calibration result will not be lost even if the backup battery is removed.

How to input the linearity polyline input data #

The ultrasonic flowmeter/heat meter can realize the non-linear multi-point linearization correction of the flow, and it can realize up to 11 segments of broken line correction. This function is turned off when leaving the factory. You can use this function when you enter the menu M48. The password is 1111.

In order to also correct the flow outside the flow range without causing a sudden change in the correction coefficient, we add two flow points 0 m3/h and 1 00000m3/h on the basis of the flow point of the coefficient that has been measured. , The coefficient of 0 m3/h uses the coefficient of the smallest flow point we measured, and the coefficient of the largest flow point we measured for 100000m3/h, and then input into M48 in order of flow point from small to large.

If you need to cancel the broken line correction function, just enter “0” in the number of broken line points in the menu M48

The following table is an example of 5-point polyline correction:

| Standard device flow (m3/h) | Standard device flow (m3/h) | Standard device flow (m3/h) |

| 0 | 0 | 1 |

| 1.02 | 0.998 | 1.02 |

| 5.11 | 5.505 | 0.93 |

| 10.34 | 10.85 | 0.95 |

| 20.45 | 19.78 | 1.03 |

| 50.56 | 51.23 | 0.99 |

| 100000 | 100000 | 1 |

How to realize calorie measurement #

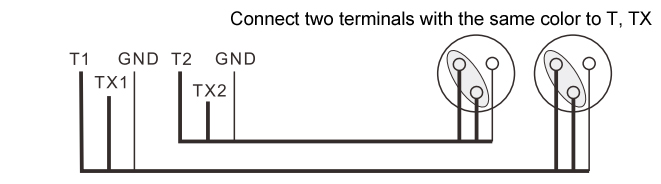

The ultrasonic flowmeter can be connected to the 3-wire PT100 to realize the heat measurement and the wiring method is as follows:

How to use SD card storage #

The external SD card memory supports mass storage of measurement parameters and measurement results.

The supported SD card capacity can be 512M~4G standard SD card. (There may be some chip SD cards that are not supported, so it is recommended to purchase an SD card from our company) In order for the SD card storage to work normally, the following settings must be made:

①Use the M50 menu to select the content option to be stored.

②Use the M51 menu to select the time to start storing, the storing time interval and the number of storing times.

Fill in the start time **:**.** to indicate the start of the current time. Filling in 9999 in the storage times means that the storage has been indefinitely for a long time.

③In the M52 menu, you must choose to send the data generated by the flowmeter to the “internal serial bus”.