In general, a single-flange liquid level transmitter can be used to measure the liquid level for an open tank, but a double flange liquid level transmitter are ideal for the liquid level measurement of a pressurized container or a vacuum container.

Liquid level control is a critical aspect of various industrial processes, ensuring the proper functioning of tanks, vessels, and pipelines. Accurate measurement of liquid levels is essential for maintaining process efficiency, preventing overflow or underflow, and ensuring the safety of equipment and personnel. In this article, we will explore the use of double flange level transmitters and dye distinguishing technology to maximize efficiency in liquid level control.

Importance of accurate liquid level measurement

Accurate liquid level measurement is crucial in industries such as oil and gas, chemical manufacturing, water treatment, and food processing. It allows operators to monitor inventory levels, prevent costly spills, optimize production processes, and ensure compliance with regulatory standards. Without precise level measurement, operators may face challenges such as inaccurate inventory management, inefficient production, equipment damage, and safety hazards.

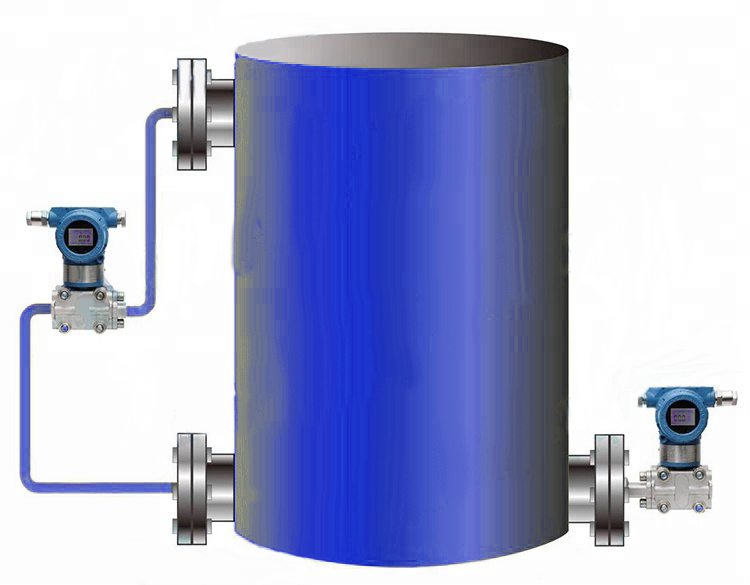

Overview of double flange level transmitters

Double flange level transmitters are advanced devices used for measuring liquid levels in tanks and vessels. These transmitters consist of a sensing element, a flange assembly, and a signal processing unit. The sensing element detects the liquid level and converts it into an electrical signal, which is then processed and transmitted to a control system or display unit. Double flange level transmitters are designed to provide accurate and reliable level measurements, even in challenging environments with high temperatures, pressure, or corrosive substances.

These transmitters are typically installed on the top or side of the tank and can be used for both continuous level measurement and point level detection. They are available in various configurations, including guided wave radar, magnetostrictive, and hydrostatic pressure types. Double flange level transmitters offer several advantages over other level measurement devices, making them a popular choice in industrial applications.

Advantages of using double flange level transmitters

- High accuracy: Double flange level transmitters provide precise and reliable level measurements, ensuring accurate inventory management, process control, and safety.

- Wide range of applications: These transmitters can be used in diverse industries and for various liquid types, including water, oil, chemicals, and food products.

- Versatile installation options: Double flange level transmitters can be mounted on the top, side, or bottom of tanks, vessels, or pipelines, making them suitable for different installation requirements.

- Robust construction: These transmitters are designed to withstand harsh operating conditions, such as extreme temperatures, high pressures, and corrosive environments.

- Easy maintenance: Double flange level transmitters require minimal maintenance, reducing downtime and ensuring continuous operation.

Soluble dyes Kinds and Characteristics

Soluble dyes are divided into water-soluble dyes and oil-soluble dyes. What are the differences between them?

Water-soluble dyes: As the name suggests, they are water-soluble dyes, that is, water-soluble dyes are mainly used for coloring clothes. The advantages are that they are simple and rough, fast and cost-effective; the disadvantage is that they are easier to decolorize, but some water-soluble dyes have already been made. Corresponding improvements.Mostly used for fabrics, sweaters and pants, silk products.

Oil-soluble dyes: As the name suggests, they are oil-soluble dyes, that is, oil solutions are used as the main color for clothing. The advantage is that they are not easy to change color after coloring, but they do not include inferior oil-soluble dyes. The quality of the garment itself is simply a fighter among dyes; the disadvantage is that it is expensive, sensitive to high temperature, sensitive to strong solvents and cannot be dry cleaned.Mostly used for leather products, silk.

Dye production wastewater contains acids, alkalis, salts, halogens, hydrocarbons, amines, nitro compounds, dyes and their intermediates, and some also contain pyridine, cyanide, phenol, benzidine, and heavy metals such as mercury, cadmium, and chromium. The composition of these wastewaters is complex. Toxic and difficult to handle. Therefore, the treatment of dye production wastewater. Should be based on the characteristics of wastewater and its discharge requirements. Choose the appropriate treatment method.

Double flange level transmitter for water-soluble dyes and oil-soluble dyes

In general, a single-flange liquid level transmitter can be used to measure the liquid level for an open tank, but for the liquid level measurement of a pressurized container or a vacuum container, a double-flange liquid level transmitter needs to be used to measure the liquid level.

For the following situations One needs to select a remote pressure/differential pressure transmitter: The measured medium is easy to solidify or crystallize when it is drawn out by a pressure-inducing tube; The measured medium contains suspended solids or is too viscous, which is easy to block the pressure-inducing tube; The medium temperature is too high or corrosive, etc., which is not conducive to direct measurement; the measured medium is food or other medium that needs to maintain sanitary conditions and cannot be polluted.

Similarly, after adding the remote transmission device, the measurement accuracy will be slightly reduced, and the response speed will become slower, especially when the capillary exceeds 10 meters and the pressure is relatively small, pay attention to the installation position to ensure that the measured pressure is within the measurement range of the basic measuring element inside.

Considerations when selecting a double flange level transmitter

When selecting a double flange level transmitter for liquid level control, several factors should be taken into account:

- Compatibility: Ensure that the transmitter is compatible with the liquid being measured, considering factors such as chemical compatibility, temperature range, and pressure rating.

- Installation requirements: Consider the available space and mounting options to select a transmitter that can be installed conveniently in your application.

- Accuracy requirements: Determine the level of accuracy needed for your specific application, as different transmitters offer varying levels of precision.

- Maintenance and reliability: Choose a transmitter that requires minimal maintenance and has a proven track record of reliability in similar applications.

Conclusion: Achieving maximum efficiency in liquid level control

Maximizing efficiency in liquid level control is crucial for optimizing industrial processes, ensuring safety, and preventing costly incidents. Double flange level transmitters, with their high accuracy and robust construction, provide reliable level measurements in challenging environments. When combined with dye distinguishing technology using water-soluble or oil-soluble dyes, operators can visually identify liquid levels, enhancing control and preventing errors. By considering the specific requirements of their applications and selecting the appropriate double flange level transmitter, industries can achieve maximum efficiency in liquid level control, leading to improved productivity, reduced costs, and enhanced safety.

CTA: If you are looking to enhance your liquid level control system, contact us today to explore the range of double flange level transmitters and dye distinguishing technology we offer. Our experts will assist you in selecting the right solution for your specific application.