Flanged magnetostrictive Top-mounted liquid level gauge is a high-precision and measurable ultra-long-stroke absolute position measuring transmitter developed by using the principle of magnetostriction, which can accurately measure the linear displacement of moving objects. Compared with conductive rubber displacement transmitter, magnetic grid displacement transmitter, resistive displacement transmitter and other products, it has obvious advantages, and one transmitter can be used to measure displacement and speed, with extremely high performance and price Compare.

The structure of the magnetostrictive displacement transmitter is composed of stainless steel casing (including measuring rod), magnetostrictive wire (waveguide wire), movable magnetic ring (with permanent magnet inside) and electronic components.

Flanged magnetostrictive Top-mounted liquid level gauge main features

* Resistant to harsh environment, high reliability and long life;

*High precision and high stability;

* High resolution

* absolute position output;

* Non-contact measurement, long life;

*With reverse polarity protection

* Anti-lightning, anti-RF interference

* Anti-vibration and shock resistance

* Exquisite structure, wide adaptability;

*Easy to install, no need for regular maintenance or calibration.

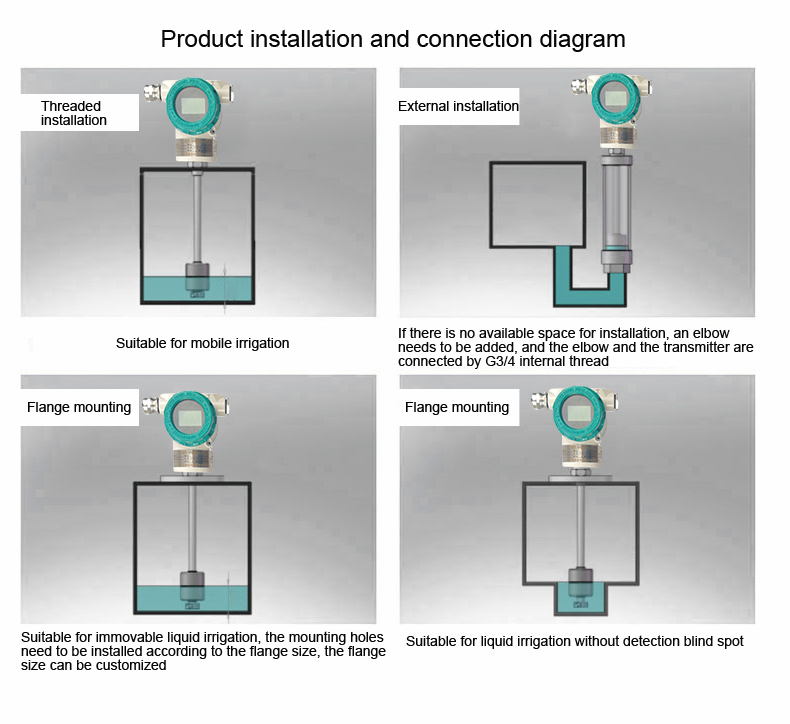

Flanged magnetostrictive Top-mounted liquid level gauge Installation requirements

1. Magnetostrictive level gauges are usually top mounted.

2. There should be no interference at the installation place of the probe rod, such as agitator, feeding port, etc.

3. The probe rod cannot be bent and subjected to force, and it is not allowed to be subjected to greater impact or vibration. The magnetic float on the probe rod should be able to slide up and down freely without being blocked by other objects.

4. The liquid level gauge must be installed vertically, and the installation slope should not be greater than 5 degrees.

5. When the level gauge is used in flammable, explosive, corrosive steam and liquid, etc., protective measures must be taken to protect it.

6. The connecting cables of the liquid level gauge must avoid high-power power supplies, radio frequency signal sources and other noisy transmission lines.

Flanged magnetostrictive Top-mounted liquid level gauge model selection guide

1. The selection of the liquid level gauge should be consistent with the on-site medium environment, including ambient temperature, pressure, vibration, shock, compatibility of structural materials and medium, etc.

2. When the temperature of the measured medium is high (100~200℃), it is recommended to select a probe with an outer buoy (option B in the selection table) and install it with side flanges. When the temperature is higher (200~300℃), it is recommended to choose the probe with side-bundled outer float (option C in the selection table), and use the side flange to install.

3. There are measurement dead zones at the upper and lower ends of the measuring probe, which should be considered when selecting the range.

4. The size of the stainless steel magnetic float commonly used in the liquid level gauge is Ф45×56×Ф15, and the flange connection of DN50 and above must be used. For the liquid level gauge with threaded connection, the user needs to install the flange or bracket by himself.