Flow sensors also referred to as flow meters or flow indicators, are crucial instruments in industrial settings, offering precise measurement of the flow of liquids, gases, or mixtures. Whether you’re a purchasing manager or an application engineer, understanding the various types of flow meters—such as gas flow meters, air flow meters, flow meter water, Venturi flow meters, magnetic flow meters, Coriolis flow meters, and clamp-on flow meters—is essential. These devices are pivotal for ensuring operational efficiency, safety, and cost-effectiveness in numerous industries. In this article, we’ll provide an in-depth look into the key factors you need to consider when selecting the right flow meter for your application.

1. Introduction: What is a Flow Meter and Why is it Essential?

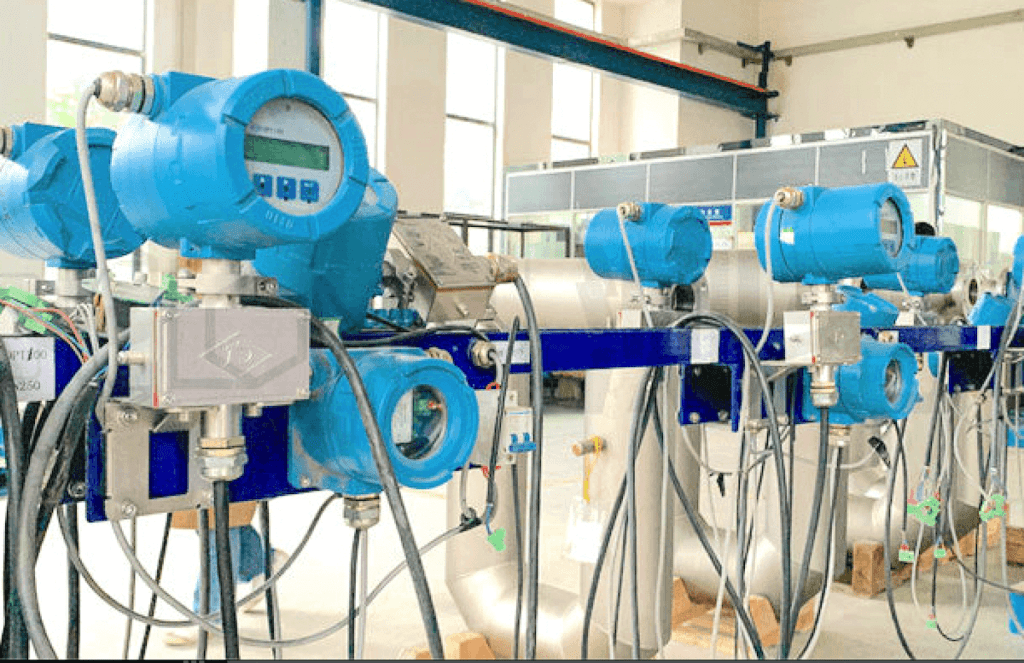

A flow meter is a device that measures the rate of fluid flow in a system, which could be a gas, liquid, or a combination. These instruments are fundamental in industries such as oil and gas, water treatment, chemical processing, and manufacturing. Flow meters not only help in monitoring the efficiency of processes but also play a critical role in maintaining product quality, ensuring safety, and optimizing resource use.

Key Importance of Flow Meters:

- Operational Efficiency: Accurately monitoring flow rates ensures that processes run smoothly and efficiently.

- Safety Compliance: In hazardous environments, precise measurement is critical for preventing leaks or explosions.

- Cost Management: Proper flow measurement can reduce wastage, leading to cost savings.

2. Measurement Principles: How Do Flow Meters Work?

Understanding the working principles of different flow meters is vital for selecting the right one for your application. Here’s a comparison of some common types:

Venturi Flow Meter

The Venturi flow meter measures flow by constricting the flow in a pipe, causing a pressure drop that is proportional to the flow rate. This meter is highly reliable for liquids and gases and is widely used in water treatment and chemical processing.

Magnetic Flow Meter

Magnetic flow meters, or mag meters, work on the principle of electromagnetic induction. They are ideal for measuring the flow of conductive liquids, such as water, and are often used in wastewater treatment and chemical industries.

Coriolis Flow Meter

Coriolis flow meters measure mass flow by detecting the twisting force generated by fluid moving through a vibrating tube. These meters offer high precision and are suitable for applications requiring accurate measurement of liquid or gas flow, like in the oil and gas industry.

Clamp-On Flow Meter

Clamp-on flow meters use ultrasonic sensors to measure flow from outside the pipe, making them ideal for situations where intrusive methods are not feasible. These meters are versatile and can be used in various industries, including HVAC and water treatment.

3. Why You Need Flow Meters: The Significance of Accurate Flow Measurement

Accurate flow measurement is critical for several reasons:

- Quality Control: Precise measurements ensure consistent product quality, especially in industries like food and beverage or pharmaceuticals.

- Regulatory Compliance: Many industries are subject to strict regulations that require accurate flow measurement for safety and environmental protection.

- Cost Efficiency: Proper flow measurement reduces material waste, energy consumption, and maintenance costs.

4. Accuracy and Precision: How Different Types of Flow Meters Perform

Accuracy and precision are key metrics that can vary significantly between different types of flow meters.

Coriolis Flow Meters

Coriolis meters are renowned for their high accuracy and precision, often achieving accuracies within ±0.1% of the actual flow. They are the gold standard for applications requiring high precision.

Magnetic Flow Meters

Mag meters offer good accuracy, typically within ±0.5% of the flow rate, making them suitable for many industrial applications where precision is important but not critical.

Venturi Flow Meters

Venturi meters provide moderate accuracy, typically within ±1% of the flow rate. While not as precise as Coriolis or magnetic meters, they are reliable and durable, making them a cost-effective choice for many industries.

Clamp-On Flow Meters

Clamp-on meters generally offer accuracy within ±1-2% of the flow rate, depending on the installation and the medium being measured. They are a flexible option for temporary installations or where the piping system cannot be altered.

5. Reliability and Durability: How Long Do Flow Meters Last?

In industrial settings, reliability and durability are as crucial as accuracy. Here’s how different flow meters stack up:

Coriolis Flow Meters

These meters are highly durable with minimal maintenance requirements, often lasting for several years in harsh environments.

Magnetic Flow Meters

Mag meters are also reliable, with a long service life and low maintenance. Their non-invasive nature makes them ideal for applications where the fluid is corrosive or abrasive.

Venturi Flow Meters

Venturi meters are extremely robust, often lasting decades with proper maintenance. Their simple design has few moving parts, reducing the likelihood of failure.

Clamp-On Flow Meters

While these meters are less durable than fixed-installation models, they offer flexibility and ease of maintenance, making them suitable for non-permanent setups or applications where the pipe material cannot be tampered with.

6. Cost Considerations: Evaluating Cost-Effectiveness

When choosing a flow meter, it’s essential to consider both the initial cost and the total cost of ownership, including maintenance and operational costs.

Initial Purchase Costs

- Coriolis Flow Meters: High initial cost due to their sophisticated technology and high precision.

- Magnetic Flow Meters: Moderate to high initial cost, depending on size and application.

- Venturi Flow Meters: Generally lower initial costs, making them attractive for large-scale installations.

- Clamp-On Flow Meters: Moderate initial cost, with additional savings in installation since they don’t require pipe modifications.

Maintenance Costs

- Coriolis and Magnetic Flow Meters: Low maintenance due to the lack of moving parts.

- Venturi Flow Meters: Low maintenance, but the need for periodic calibration might increase costs over time.

- Clamp-On Flow Meters: Very low maintenance costs, primarily associated with sensor upkeep.

7. Use Cases: Selecting the Right Flow Meter for Your Application

Different flow meters excel in different environments and use cases. Here are some scenarios where each might be preferred:

Coriolis Flow Meters

- Application: High-precision chemical dosing, oil and gas custody transfer.

- Reason: Unmatched accuracy and reliability in measuring mass flow, even in challenging conditions.

Magnetic Flow Meters

- Application: Wastewater treatment, chemical processing.

- Reason: Ideal for measuring the flow of conductive liquids, with robust performance in corrosive environments.

Venturi Flow Meters

- Application: Water distribution, large-scale industrial processes.

- Reason: Cost-effective and durable, suitable for large pipes and high-volume flow measurement.

Clamp-On Flow Meters

- Application: HVAC systems, temporary flow measurement setups.

- Reason: Non-invasive installation, ideal for retrofitting or when pipe integrity must be preserved.

Conclusion: How to Choose the Right Flow Meter for Your Needs

Selecting the right flow meter depends on various factors, including the type of fluid, required accuracy, installation constraints, and budget. For purchasing managers and application engineers, it’s crucial to balance these factors to find the most cost-effective and reliable solution.

1. Information Requirements:

- Continuous or totalized flowrate: Do you need real-time data or cumulative measurement?

- Local or remote data: If remote, determine how the data will be transmitted (analog/digital) and how frequently it needs to be updated.

2. Fluid and Flow Characteristics:

- Understand the physical properties of the fluid, such as pressure, temperature, density, and viscosity.

- Also, consider the fluid’s composition and how it behaves during operation—any tendencies to form bubbles, contain solids, or coat surfaces.

3. Pressure & Temperature Ranges:

- Define the operational ranges of pressure and temperature, including extremes and normal values.

- Identify other flow conditions like the potential for reverse flow, slug flow, or pulsation.

4. Piping and Installation Area:

- Consider the piping dimensions, materials, and layout, including straight-run requirements.

- Also, take note of the environmental conditions like the presence of vibration, magnetic fields, or hazardous areas that could affect installation and performance.

5. Key Questions to Ask:

- What’s the fluid type? Do you need rate or totalized data?

- What’s the required flow range, pressure, and temperature?

- What display and output options are needed?

6. Flow Rates and Accuracy:

- Define the minimum and maximum flow rates and the desired accuracy (in %AR, %CS, or %FS).

- Understand the importance of accuracy vs. repeatability based on your specific application.

7. Accuracy vs. Repeatability:

- Favor flow meters without moving parts to reduce issues related to wear and calibration.

- Choose a full flow meter over point sensors when accuracy across the full flow range is important.

8. Mass or Volumetric Units:

- Decide whether mass flow or volumetric flow measurement is more appropriate for your fluid.

- For compressible fluids, mass flow is often more reliable, while for liquids, suspended bubbles or varying density may affect volumetric flow accuracy.

When in doubt, consult with a flow meter manufacturer or request a product demo to understand how a particular device will perform in your specific industrial environment. Investing in the right flow meter can enhance operational efficiency, reduce costs, and ensure compliance with industry standards.