Flush diaphragm pressure sensor is also commonly known as: Flat film pressure sensor, Diaphragm pressure transmitter, Paint pressure sensor, Food pressure sensor, Diaphragm pressure sensor, Diaphragm pressure transmitter Or sanitary pressure transmitter.

Flush diaphragm pressure sensor, including strain type and diffused silicon front type.

The strain-type flush-membrane measuring end adopts a special, sturdy flush diaphragm. Hard particles in the measured medium will not damage the isolating diaphragm. Compact structure, corrosion resistance, anti-vibration, anti-particle impact, wide temperature compensation.

Diffusion silicon front type is made of imported diffusion silicon core. Use calibration and digital compensation technology. The product has reliable performance and stable output.

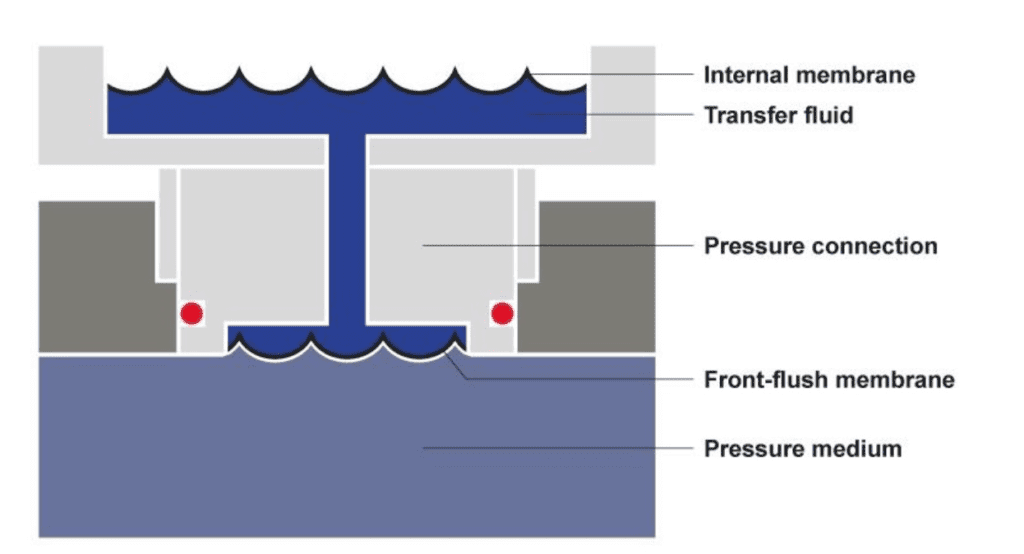

What is the Flush diaphragm pressure sensor working principle ?

PM428 Flush diaphragm pressure sensors use processes such as diffusion or ion implantation to form resistors and connect them to a Wheatstone bridge. Micro-machining technology is used to form a pressure-sensitive diaphragm under the bridge. When pressure is applied to the diaphragm, the resistance value changes and a linearized output signal is generated that is proportional to the applied pressure. When we add DC power to the Wheatstone bridge, a DC voltage signal will be output. After the second conversion line, the two-wire system 4 ~ 20MA output is realized.

Where is flush diaphragm pressure transmitter used for ?

The sensor’s Flush diaphragm structure prevents problems such as scaling, unsanitation, and sticky liquid clogging. Widely used in food, pharmaceutical, brewing and other process control fields. It is suitable for the pressure measurement and control of viscous media such as chemical coatings, paints, muds, asphalts, and crude oil under weak pressure.

What common types of pressure can you measure with a flush pressure sensor?

We use three common types in the industry.

- The first is “gauge pressure”. Measured with reference to atmospheric pressure (typically 14.7 PSI). When above atmospheric pressure, you will display a “positive” pressure; when below atmospheric pressure, you will display a “negative” pressure.

- The next is “absolute pressure“. In short, this is the pressure relative to an absolute vacuum measurement. The absolute pressure of the full vacuum is zero PSIa and it increases from there. This type of sensor can be used if it is necessary to read pressures below atmospheric pressure.

- The last type that is usually monitored in the industry is “pressure differential”. It sounds like this, the difference between two pressures, a measured pressure and a reference pressure.

How to check the flush diaphragm pressure sensor ?

1. Turn on the power supply without applying pressure to test whether the zero output is normal; Long-term stability of the pressure sensor is ±0.1%FS/year (typical), ±0.2%FS/year (maximum)

2. Apply pressure to the sensor and turn on the power supply to test whether the output changes. Or check whether there is overload damage inside the sensor. PM420 pressure sensor overload pressure up to 2 times full scale. (Below 10MPa ≤ 2 times full scale10MPa and above ≤1.5 times full scale)

If the above checks are normal, the sensor is normal, otherwise the sensor is damaged!