What is a differential pressure transmitter ?

The differential pressure transmitter is used to prevent the medium in the pipeline from entering the transmitter directly. The pressure sensing diaphragm and the digital pressure transmitter are connected by a capillary filled with fluid. It is used to measure the liquid level, flow and pressure of liquid, gas or steam, and then convert it into 4 ~ 20mA DC signal or digital signal output.

The Components of Differential Pressure Transmitter

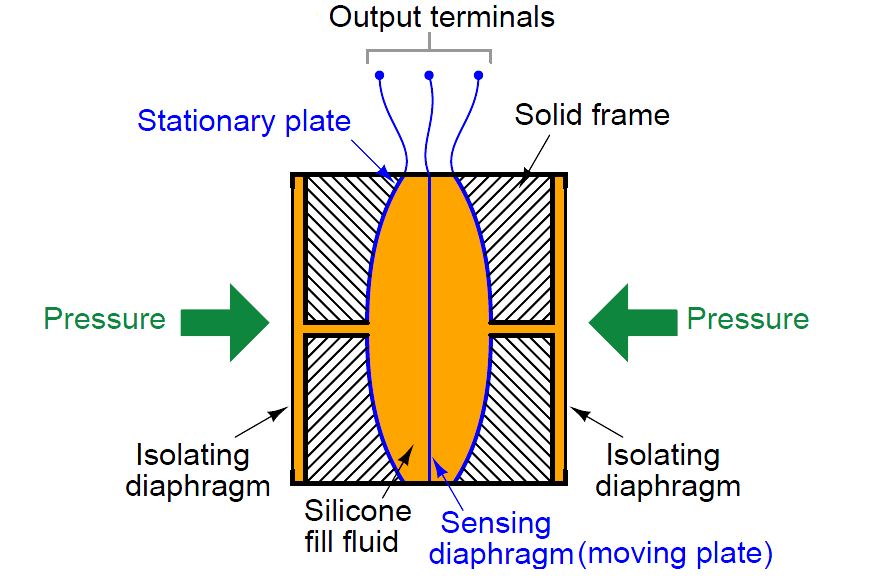

Differential pressure transmitters are comprised of a robust electronic module and two sensory diaphragms that provide the electronic reading of applied forces in a containment vessel. These arrangements are physically connected in set configurations depending upon the application requirements.

Applied pressure readings are acquired by the diaphragms, which register pressure as surface deformation and translate that value into an electronic signal. This signal is transferred to the differential pressure module, which compares the two values and expresses the pressure difference as a value of pounds per square inch (psi), bar, or kilopascals (kPa). These diaphragms are all-welded to maintain the container integrity in vacuum conditions and for wet leg applications, such as level measurement in crude oil distilleries.

Electronic differential pressure transmitter working principle

As the name suggests, the result measured by the differential electronic transmitter is the pressure difference, i.e. △ P= ρ g△h。 Since the oil tank is often cylindrical and the area s of its cross-section circle is constant, then the gravity g = △ P · s= ρ G △ h · s, s remains unchanged, and G is positively correlated with △ P. That is, as long as the △ p value is accurately detected, it is inversely proportional to the liquid level height h and positively correlated with the height difference △ h. When the temperature changes, although the oil volume expands or shrinks and the actual liquid level increases or decreases, the detected pressure remains unchanged. If the user needs to display the actual liquid level, it can also be solved by introducing medium temperature compensation.

How Does a Differential Pressure Sensor Work?

Typically, the two pressures to be measured are applied to opposite sides of a single diaphragm. The deflection of the diaphragm, either positive or negative concerning the resting state, determines the pressure difference. Some industrial differential sensors use two separate absolute sensors with internal electronics to calculate and provide the pressure difference. Another way to achieve a differential pressure measurement is by using two absolute pressure sensors and then calculating the difference on an industrial control system. This is useful in situations where two different types of sensors are required because of either the medium being measured (i.e. a liquid and a gas) or the environment of the measurement.

What are the advantages of differential pressure transmitter?

The differential pressure transmitter is applicable to the following measurement and control situations:

*Viscous medium at high temperature

*Crystallizable medium

*A medium with solid or suspended particles

*Strongly corrosive or highly toxic medium

*The liquid differential pressure transmitter can eliminate the phenomenon that the leakage of impulse pipe pollutes the surrounding environment; It can avoid the tedious work of often replenishing the isolation liquid due to the instability of the measurement signal when using the isolation liquid.

*Continuous and accurate measurement of interface and density

The remote transmission device can avoid the mixing of different instantaneous media, so that the measurement results can truly reflect the actual situation of process change, This works even with a low range differential pressure transmitter.

*Occasions requiring high hygiene and cleanliness

For example, in the production of food, beverage and pharmaceutical industries, not only the parts of the transmitter contacting the medium are required to meet the hygienic standards, but also it should be easy to wash, so as to prevent cross contamination of different media.

How to calibrate the differential pressure transmitter on site?

Calibration of conventional differential pressure transmitter:

First adjust the damping to the zero state, first adjust the zero point, and then fill the pressure to adjust the full range to make the output 20mA. The on-site adjustment is fast. Here is the fast adjustment method of zero point and range. Zero adjustment has little effect on the full scale, but it has an effect on the zero point. Without migration, the effect is about 1 / 5 of the range adjustment, that is, if the range is adjusted upward by 1mA, the zero point will move upward by about 0.2mA, and vice versa. For example: the input full-scale pressure is 100KPA, the reading is 19.900ma, and adjust the range potentiometer to make the output 19.900 + (20.000-19.900) × 1.25=20.025mA. If the range increases by 0.125ma, the zero point increases by 1 / 5 × 0.125=0.025. Adjust the zero potentiometer so that the output is 20.000ma After the zero point and full scale adjustment are normal, check the middle scales to see if they are out of tolerance? Fine tune if necessary. Then adjust the migration, linearity and damping.

Calibration of intelligent differential pressure transmitter

It is impossible to calibrate the smart transmitter with the above conventional methods, because it is determined by the structural principle of Hart transmitter. Because between the input pressure source and the generated 4-20mA current signal, in addition to the machinery and circuit, the intelligent transmitter also has the operation of the input data by the microprocessor chip, so the adjustment is different from the conventional method. In fact, the manufacturer also explains the calibration of intelligent transmitters. For example, for ABB transmitters, the calibration can be divided into “set range”, “rerange” and “fine adjustment”. The “range setting” operation mainly completes the configuration through the digital setting of LRV and urv, And “rerange” “Operation requires the transmitter to be connected to a standard pressure source and guided by a series of commands. The transmitter will directly sense the actual pressure and set the value. The initial and final setting of the range directly depends on the real pressure input value. However, it should be noted that although the relationship between the analog output of the transmitter and the input value used is correct, the digital reading of the process value will show a slightly different value, which can be corrected by fine-tuning items accurate Since each part needs to be adjusted separately and jointly, the actual calibration can be carried out according to the following steps:

1. First make a 4-20mA fine adjustment to correct the D / a converter inside the transmitter. Since it does not involve sensing components, there is no need for external pressure signal source.

2. Make another whole process fine-tuning to make the 4-20mA digital reading consistent with the actually applied pressure signal, so the pressure signal source is required.

3. Finally, rerange and adjust the analog output of 4-20mA to match the external pressure signal source. Its function is exactly the same as that of the zero (z) and range (R) switches on the transmitter shell.

For the differential pressure transmitter calibration procedure pdf, please contact our engineer.

How to install differential pressure transmitter?

Differential pressure transmitter is the most commonly used weight transmitter in industrial practice. It is used to prevent the medium in the pipeline from entering the transmitter directly. The pressure sensing diaphragm and the transmitter are connected by capillary filled with fluid are called the differential pressure transmitter capillary type. It is used to measure the liquid level, flow and pressure of liquid, gas or steam.

Installation Tips for Differential Pressure Transmitters

We often get questions about where to mount differential pressure transmitters in relation to the pipe mounted flow element. There are three different types of fluids that you will want to measure and they require different mounting method.

First, is dry gases. The DP transmitter must be mounted vertically above the pipe taps so that all potential liquid or condensation in the line will drain back into the pipe.

Second is liquids. The DP will be mounted vertically below the pipe so that the line will always stay full with liquid.

The third is condensing liquids such as steam.

These require that the DP transmitter is mounted below the pipe taps, but they must have a vertical water column that is always filled with the same amount of condensate so that the water pressure on the impulse lines remains consistent. The water column will block the high-temperature steam from cooking your transmitter.

If you mount it above the pipe and there is no water present, the 300F+ heat will break your transmitter.

How to select differential pressure transmitter?

Differential pressure transmitter is used to measure the pressure difference of medium in process pipeline or tank, and convert the measured differential pressure value into current signal output through data conversion and square root. The following parameters need to be known when selecting differential pressure transmitter:

1. Differential pressure value

2. Medium

3. Working pressure of medium

4. Operating temperature of medium

5. Is it intelligent or analog

Solutions

As one of the earliest differential pressure transmitter manufacturers, SenTec provide a wide variety differential pressure transmitter measurement solutions, also include the rosemount differential pressure transmitter substitutes etc.

For specific differential pressure transmitter price, please contact our sales engineer.