Piezoresistive Differential Pressure Transmitter utilizes the piezoresistive effect of semiconductor silicon materials. Realize accurate measurement of differential pressure.

What is a Differential Pressure Transmitter?

Differential pressure (DP) transmitter, also known as differential pressure transducer. The most common and useful industrial pressure measuring instrument is DP transmitter.

A differential pressure transmitter measures the difference between two pressures. The differential pressure transmitter converts the pressure measurement to a proportional 4-20 mA or 1-5 Vdc output signal. Used as input for controllers, recorders, indicators or similar devices.

The DP transmitter will sense the pressure difference between the two ports according to the calibrated pressure range and generate an output signal. Industrial differential pressure transmitters are made of two housings.

The pressure sensing element is located in the lower half, and the electronic element is located in the upper half. It will have two pressure ports labeled “High” and “Low”. The high-pressure port is always in a high-pressure state. It is not mandatory that the low-voltage port is always in a low-voltage state. This mark is related to the effect of the port on the output signal.

DP readings can be negative or positive, depending on the low-end or high-end. If the low-pressure side is open to the atmosphere, the DP transmitter can be used as a gauge pressure transmitter.

SenTec is the 3151 dp transmitters manufacturer.

What is a piezoresistive pressure sensor?

Piezoresistance pressure sensor (piezoresistance type transducer) is a kind of pressure sensor. Piezoresistive pressure sensors, also known as diffused silicon pressure sensors, refer to sensors made using the piezoresistive effect of single crystal silicon materials and integrated circuit technology. The single crystal silicon material is subjected to force. The resistivity changes. The electrical signal output proportional to the force change can be obtained through the measuring circuit. Piezoresistive sensors are used for the measurement and control of pressure, tension, pressure difference, and other physical quantities that can be transformed into changes in force. Such as liquid level, acceleration, weight, strain, flow rate, vacuum degree.

Strain pressure sensor VS piezoresistive pressure sensor

1.In principle, strain-type pressure sensors are caused by changes in the geometry (length or width) of the strained material caused by external pressure (or tension). This in turn causes the resistance of the material to change. The magnitude of the external force can be measured by detecting this resistance change.

2.Piezoresistive pressure sensors are usually semiconductor pressure sensitive materials. After the semiconductor piezoresistive sensor is subjected to external forces, its own geometry hardly changes. Instead, its lattice parameters change, affecting the width of the forbidden band. Even a very small change in the width of the forbidden band will cause a large change in carrier density. This eventually causes the resistivity of the material to change.

How does a piezoresistive differential pressure transmitter work?

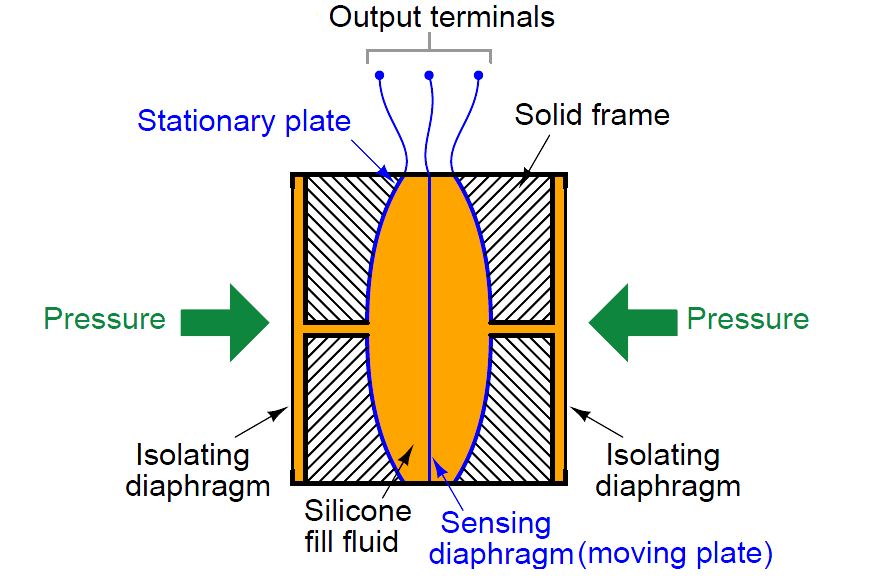

The sensitive element of the piezoresistive differential pressure transmitter is a solid piezoresistive sensitive chip. Silicone oil is filled between the chip and the two corrugated diaphragms.

The measured differential pressure acts on the corrugated diaphragms at both ends. The differential pressure is transmitted to the sensitive chip through silicone oil. The sensitive chip is connected to the special amplifier circuit through the wire. It utilizes the piezoresistive effect of semiconductor silicon materials.

To achieve the conversion of differential pressure and electrical signals. The signal output from the Wheatstone bridge on the sensitive chip has a good linear relationship with the differential pressure.