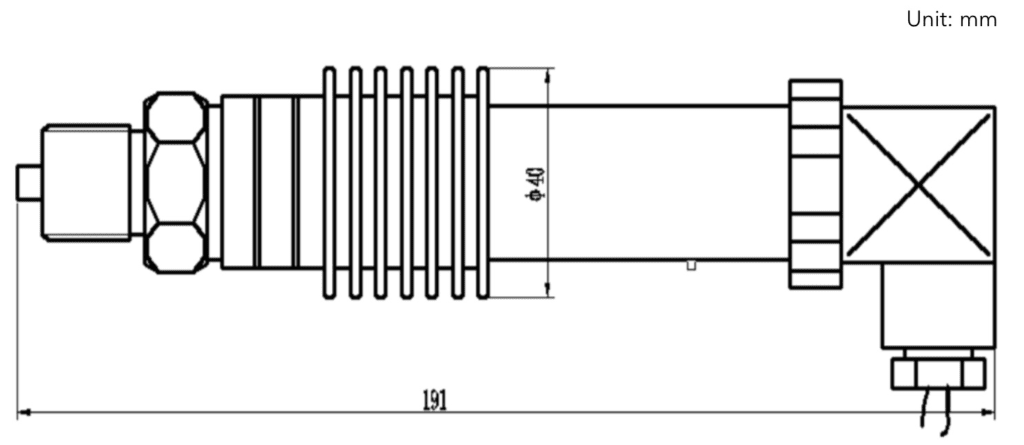

The pressure transmitter cannot directly contact the high-temperature medium. Prolonged contact with high-temperature media can easily damage the pressure sensor. Usually when measuring high temperature media, the pressure transmitter will be equipped with a stainless steel heat sink device. Avoid direct contact between the medium and the transmitter. A condensing tube can also be added on the basis of the heat sink to reduce the damage to the transmitter caused by excessive temperature.

SenTec PM424 high temperature pressure transducer/transmitter designed with Cooling Element, which can measureLiquids or gases up to 850 ° C. Such as steam, food processing & engine monitoring.

How the pressure transmitter measure high temperature media ?

Generally, the design method is to reduce the temperature near the pressure transmitter by incorporating mechanical cooling components to dissipate heat.

The cooling assembly may be filled with oil and isolated from the process medium by the isolation diaphragm.

Alternatively, the cooling assembly may include a hollow tube. The shape of the hollow tube is designed to increase heat transfer. This allows the process medium that is allowed to pass to be lowered to a much lower temperature.

The cooling element usually relies on the principle of convection heat transfer. This convective heat transfer principle is a mechanism for transferring heat due to the movement of fluid.

How does high temperature pressure sensor application for steam pipeline?

Pure steam pipes have good mechanical properties and thermal insulation properties. Under normal circumstances, it can withstand a high temperature of 120 ° C. It can withstand a high temperature of 180 ° C by modification or in combination with other thermal insulation materials. It is suitable for thermal insulation of various cold and hot water high and low temperature pipelines. The pressure detection in the steam pipeline is very important. And because of the high temperature characteristics in the pipeline. Therefore, it is suitable to use the high temperature pressure transmitter designed by our company for such occasions.

How to select a pressure transducer for high temperature environments?

Define your high temperature pressure transmitter requirements using this checklist: Process temperature, Cooling mechanism, Ambient temperature, Pressure range, Output signal, Process connection etc.

How to take off a high temperature sensor on the liquid line?

Generally, the pressure sensor is installed behind the pressure valve. When you need to remove the pressure sensor, simply close the pressure valve.

When purchasing a pressure transmitter, the manufacturer will recommend configuring a valve block. Or according to the measurement situation, install the pressure guiding tube. This can facilitate the installation and disassembly of the pressure transmitter, while ensuring continuous flow of the pipeline.