Magnetostrictive linear displacement (liquid level) transmitter mainly used to measure water and oil interface level, which is mainly composed of a measuring rod, an electronic bin and a non-contact magnetic ring (floating ball) sleeved on the measuring rod. A magnetostrictive wire (waveguide wire) is installed in the measuring rod.

How the Magnetostrictive liquid oil Level Transmitters works ?

Magnetostrictive Level Transmitters are level sensors for continuous level measurement. It is the best technology for monitoring and controlling liquid level interface.

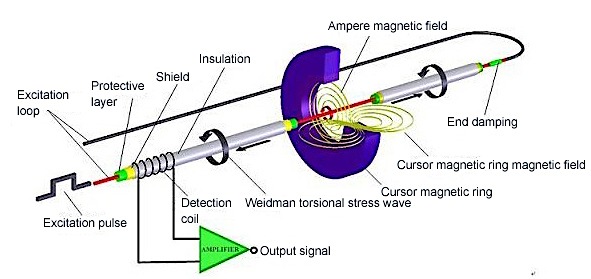

The structural part of the magnetostrictive liquid level sensor is composed of stainless steel tube (measuring rod), magnetostrictive wire (waveguide wire), movable float (with permanent magnet inside) and other parts, as shown in the figure.

When the sensor works, the circuit part will excite a pulse current on the waveguide wire, and when the current propagates along the waveguide wire, a pulsed electromagnetic field will be generated around the waveguide wire. There is a float outside the measuring rod of the sensor, which can move up and down along the measuring rod with the change of the liquid level. Inside the float there is a set of permanent magnetic rings. When the magnetic field of the pulse current meets the magnetic field of the magnetic ring generated by the float, the magnetic field around the float changes so that the waveguide wire made of magnetostrictive material generates a torsional wave pulse at the position of the float. The waveguide wire is returned and detected by the detection mechanism. By measuring the time difference between the pulse current and the torsional wave, the position of the float, that is, the position of the liquid surface, can be accurately determined.

Magnetostrictive liquid oil level gauge application

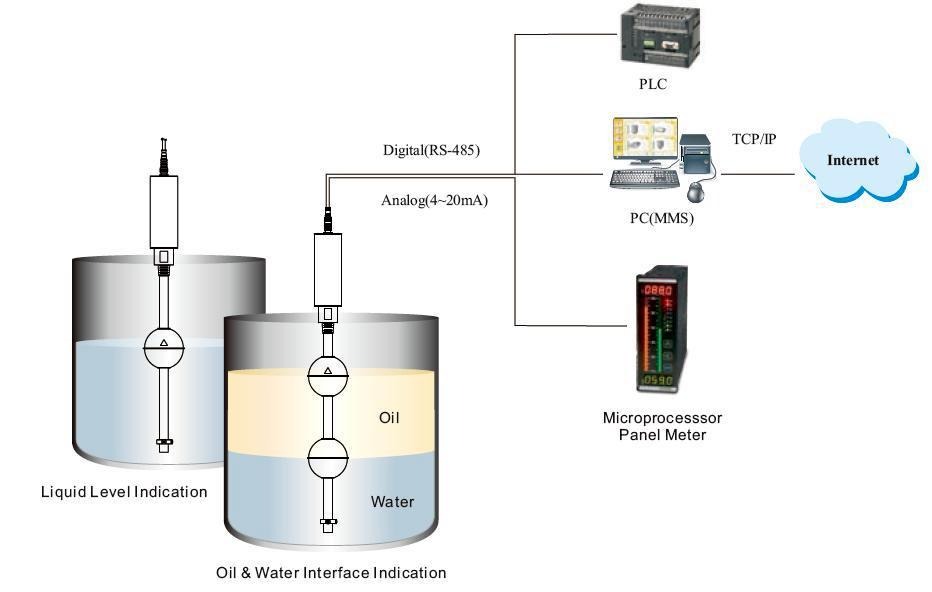

Magnetostrictive liquid level gauge is used for industrial measurement and control of liquid level in various liquid tanks such as petroleum, chemical raw material storage, industrial process, biochemical, pharmaceutical, food and beverage, tank farm management and gas station underground storage, dam water level, reservoir Water level monitoring and sewage treatment, etc.

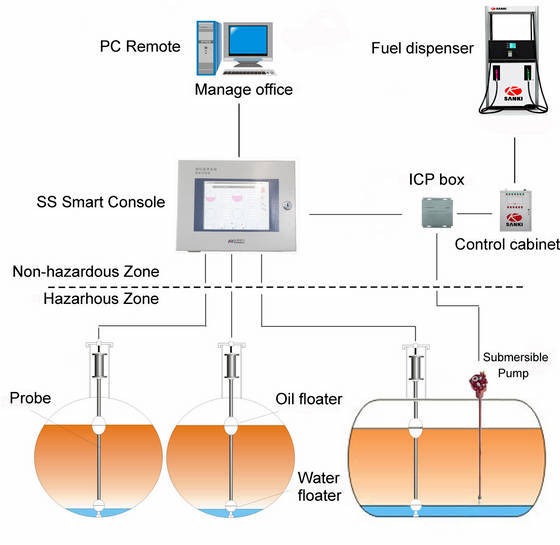

SRM901 tank gauge smart console is a powerful product developed and produced by SenTec. Together with magnetostrictive liquid level meter constitute the complete automatic tank gauge system.

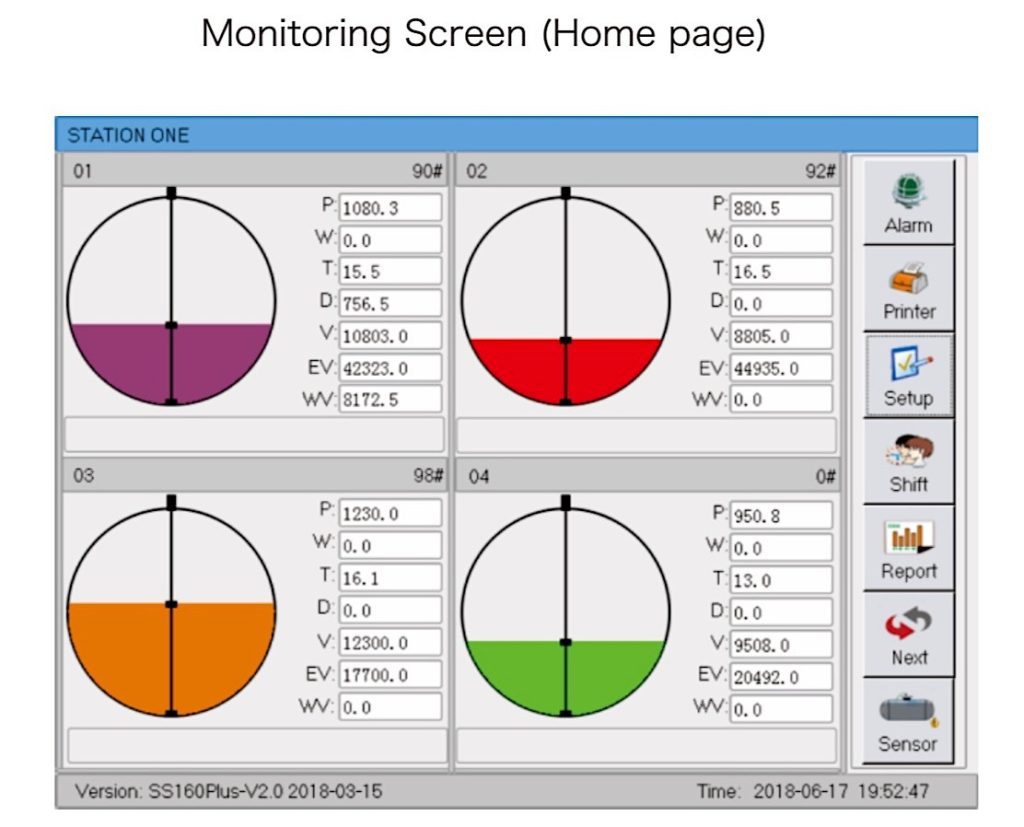

The smart console is the display terminal of the automatic tank gauge system and can detect 1to12 tanks at the

same time. lt can monitor product level, water level, temperature,product volume,water volume, empty volume, all kinds ofalarms,inventory and delivery information in real time.

International graphic touch screen and user-friendly icons makes it is easy for new user.

Smart console (please see below) is a powerful operation platform,the data processing and record center, can communicate with probe by RS485, and also offer safety and reliable power to probe.

lt consists of TFT colorful touch screen,coreprocessing CPU, safety barriers and power module. Display and operating screen is 8″ size, 800*600 resolutions. The CPU which composed of the advanced embedded processor and peripheral circuit is the control center of the whole tank gauge system. The safety

barrier is intrinsic safe parts, offer safety power to probe.

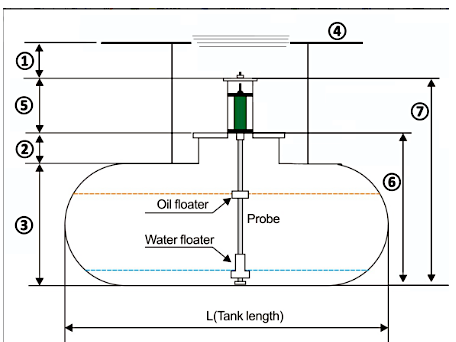

How to choose tank level gauge probe length?

For SRM901 probe, different lengths mean different specification. For example, SRM901-2870, which means the model is SRL901, length of probe rod (below probe head) is 2870mm. The selection of probe length as below:

Probe length = Probe length⑥=Tank diameter③+Manhole height②+minimum80mm

①—Minimum distance from top of riser pipe to manhole well cover

②—Manhole height

③—Tank diameter

④—Ground surface

⑤—Riser pipe (inner diameter 4 inches and height 35cm is suggested)

⑥—Probe length

The tank gauge smart console can display 1 to 12 tanks information at the same time, after correct installation and power on, the console will show boot screen,then will enter the main display interface.

At the main interface, user can easily view the information of each tank, including product type, product volume, empty volume, product level, water level, and temperature.

The price of a magnetostrictive level transmitter is determined based on the measurement conditions. SenTec is a manufacturer of magnetostrictive level gauges. We offer magnetostrictive level gauges at the right price.

※Note: The corresponding management system software can be prepared according to the requirements of use, which can realize the display of the liquid level height, temperature, volume, mass, density and other parameters of each medium, and can automatically generate reports and print, network distribution, remote accurate monitoring and other advanced advanced technology management functions.

For specific Magnetostrictive level transmitter price, please contact our sales engineer.