The pressure transducer is a commonly used pressure instrument and has certain applications in many industries. It is very important for the user to determine how to detect a pressure transducer error when using the pressure transducer. The detection items of the pressure transducer are different according to the purpose, and of course the detection method will also be different.

3 common methods to test a pressure transducer

Today we have sorted out 3 commonly used detection methods for pressure transducers, hoping to help everyone.

1. Zero point detection: By using the voltage range of the multimeter to detect the zero point output of the transducer without applying pressure. This output is generally a mV level voltage. If it exceeds the technical specifications of the mv pressure transducer, it means that the zero point deviation of the transducer is out of range.

2. Bridge circuit detection: it mainly to detect whether the circuit of the transducer is correct, generally a Wheatstone full bridge circuit, using the ohm gear of the multimeter, the impedance between the input terminals and the impedance between the output terminals, these two impedances It is the input and output impedance of the pressure transducer. If the impedance is infinite, the bridge is disconnected, indicating that there is a problem with the transducer or the definition of the pin is not correctly judged.

3. Pressure detection: the method of checking the order is: supply power to the transducer, try to pressurize the pressure transducer by hand, and use the voltage range of the multimeter to detect the voltage change at the output end of the transducer. If the pressure transducer sensitivity is large, this amount of change will be significant. If there is no change at all, you will need to switch to an air pressure source to apply pressure.

Through the above methods, the status of a transducer can basically be detected. If accurate detection is required, it is necessary to use a standard pressure transducer calibration equipment pressure source to apply pressure to the pressure transducer, and calibrate the pressure transducer according to the magnitude of the pressure and the variation of the output signal. And when conditions permit, temperature detection of relevant parameters is carried out.

The best method to test a pressure transducer

Pressure transducers are precise instruments, and like all instruments, they are prone to failure. Figuring out whether the pressure transducer is working properly or not is quite complex. This is because, in most instances, you will not be able to see or understand pressure buildup in a container without the help of specialized equipment. The best method to see if a pressure transducer is working or not is to troubleshoot it with a voltmeter.

Connect the pressure transducer to the voltmeter, and excite the transducer with the proper excitation voltage. Now measure the voltage output of the pressure transducer at zero load. Record the voltage and compare it to the no-load voltage specification mentioned in the pressure transducer suppliers datasheet.

If the measured value does not correlate, the pressure transducer is not working correctly.

Pressure transducer installation is important before the test. It allows you to determine any faults in the system. If you install a faulty pressure transducer, you are likely to get false pressure data, which can lead to undesirable results. Testing pressure transducers at certain intervals is also a good practice to ensure that it is working well and within the right specifications.

3 different pressure transducer wring Types

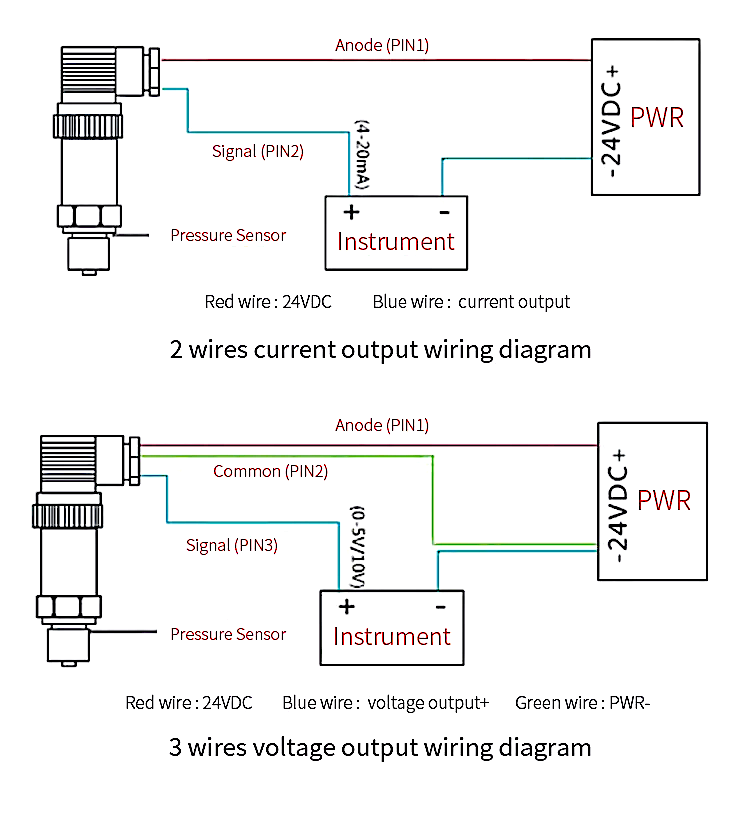

Pressure transducer circuit diagram must be clear before you do the test. Follow the steps mentioned below to test a pressure transducer with different wiring.

2 wire pressure transducer wiring diagram

- Connect the +ve terminal of the transducer to the +ve terminal of the power supply

- Connect the -ve terminal of the transducer to the +ve lead on the multimeter

- Connect –ve lead of the multimeter to the –ve terminal on the power supply

Under no-load conditions, the transducer must produce a current ranging from 4 to 20mA. The exact values corresponding to different pressure readings are usually specified in the pressure transducer manufacturer’s datasheet. Refer to the datasheet and verify if the transducer is working within specs.

3 wire pressure transducer wiring diagram

- Connect +excitation terminal on the transducer to the +ve terminal of the power supply

- Connect common terminal of the transducer to the -ve terminal of the power supply

- Connect +ve leads of the multimeter to the +ve out terminal of the transducer

- Connect -ve lead of multimeter to the common terminal

Under no load, the transducer must produce a voltage that corresponds to the manufacturer’s datasheet. If the values are identical, then the pressure transduce is working perfectly, if the values aren’t similar, then there is likely an issue with your pressure transducer.

4 wire pressure transducer wiring diagram

- Connect +24 VDC to the transducer’s +excitation

- Connect -24 VDC to the transducer’s -excitation

- Connect +ve lead of the voltmeter to the +ve lead of transducer

- Connect –ve lead of the voltmeter to the –ve lead of transducer

In no-load condition, the 4 wire pressure transducer must output a voltage equal to the no-load voltage specified in the datasheet.

In conclusion

Once the pressure transducer is found to be faulty, it should be tested according to different phenomena and problems. Before testing, be sure to pay attention to the different wiring of different transducers and test methods. SenTec provide a variety of OEM pressure transducer. You can lear more from our product page.