K type thermocouple are widely used in temperature measurement due to their accuracy, reliability, and versatility. They are composed of two different metals, usually nickel-chromium and nickel-aluminum, which generate a voltage proportional to the temperature difference between the two junctions. This voltage can be measured and converted into a temperature reading. K type thermocouples are commonly used in various industries, including manufacturing, HVAC, automotive, and scientific research.

How K Type Thermocouple Work

K type thermocouple operate based on the principle of the Seebeck effect. When two dissimilar metals are joined together at both ends, a temperature gradient across the junctions induces a voltage. This voltage is a direct result of the temperature difference and can be measured using a millivolt meter. The voltage generated is linearly proportional to the temperature difference, allowing for accurate temperature measurements.

Advantages of K Type Thermocouples

K type thermocouple offer several advantages over other types of temperature sensors. Firstly, they have a wide temperature range, typically from -200°C to 1370°C, making them suitable for a wide range of applications. Secondly, they have a rapid response time, providing real-time temperature readings. Additionally, K type thermocouples are highly durable and can withstand harsh environments, such as high pressure, vibration, and corrosive substances. They are also relatively inexpensive and easy to replace.

Common Applications of K Type Thermocouples

K type thermocouples find applications in various industries. In the manufacturing industry, they are used for temperature monitoring in processes such as heat treatment, metal casting, and soldering. In the HVAC industry, they are employed in temperature control systems for heating, ventilation, and air conditioning. thermocouples are also used in scientific research laboratories for precise temperature measurements. Furthermore, they are commonly utilized in automotive engines for monitoring exhaust gas temperatures and preventing overheating.

Understanding the Temperature Range of K Type Thermocouple

The temperature range of K type thermocouples is crucial to consider when selecting the appropriate thermocouple for a specific application. The lower limit of -200°C makes them suitable for cryogenic applications, while the upper limit of 1370°C allows for measurements in high-temperature processes. It is important to note that the accuracy of the thermocouple may vary at extreme temperatures, and special considerations may be required for accurate readings in these ranges.

Choosing the Right K Type Thermocouple Wire

To ensure accurate temperature measurements, it is essential to select the right type of K type thermocouple wire. The wire material should be compatible with the temperature range and environment of the application. Commonly used materials include nickel-chromium (positive leg) and nickel-aluminum (negative leg). It is also important to consider the insulation material of the wire, which should be able to withstand the operating temperature and any environmental factors, such as moisture or chemicals.

SenTec as a outstanding K type thermocouple manufacturer provide OEM and OEM thermocouple for worldwide

Color Coding of K Type Thermocouple Wires

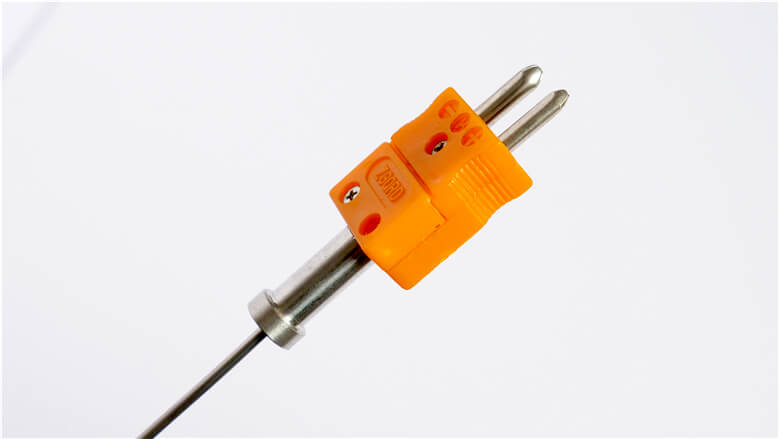

K type thermocouple wires are color-coded to facilitate easy identification and proper connection. The positive leg wire is typically yellow, while the negative leg wire is usually red. Additionally, there is an overall sheath color that indicates the thermocouple type. For K type thermocouples, the sheath color is typically yellow. It is crucial to follow the color coding when connecting the wires to ensure accurate temperature readings.

Connecting and Installing K Type Thermocouples

Proper installation and connection of K type thermocouples are essential for accurate temperature measurement. The thermocouple wires should be securely connected to the measurement instrument using appropriate connectors or terminal blocks. It is important to ensure proper insulation and avoid any short circuits or loose connections that may introduce measurement errors. Additionally, the thermocouple junction should be adequately protected and positioned in the desired location for accurate temperature readings.

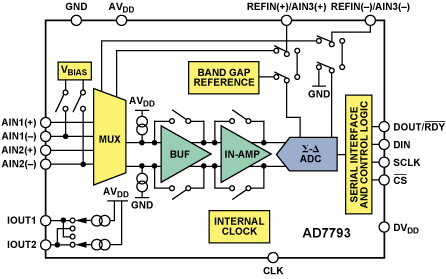

Accuracy and Calibration of K Type Thermocouples

The accuracy of K type thermocouples can vary depending on various factors, including the quality of the thermocouple wire, the measurement instrument, and the calibration process. Regular calibration is necessary to maintain accurate temperature readings. Calibration can be performed using reference temperature standards or calibration equipment. It is recommended to calibrate the thermocouples periodically to ensure reliable and precise temperature measurements.

Comparing K Type Thermocouples with J Type Thermocouples

While K type thermocouples are widely used, it is important to understand their differences compared to other thermocouple types, such as J type thermocouples. J type thermocouples are composed of iron and constantan and have a narrower temperature range of -210°C to 760°C. They are commonly used in lower temperature applications. The choice between K type and J type thermocouples depends on the specific temperature range and accuracy requirements of the application.

Important Considerations when Using K Type Thermocouples

When using K type thermocouples, there are some important considerations to keep in mind. Firstly, the thermocouple wires should be protected from any mechanical stress or damage that could affect their accuracy. Secondly, the ambient temperature should be taken into account, as it can influence the accuracy of the temperature measurement. Additionally, proper grounding and shielding techniques should be employed to minimize electrical interference.

Conclusion

K type thermocouples are crucial for temperature measurement in diverse industries. Their precision, dependability, and extensive temperature range establish them as a favored option for numerous applications. Comprehending the operational principles of K type thermocouples, their benefits, and correct techniques for installation and calibration are imperative in acquiring precise temperature readings. By carefully considering the unique demands of each application and adhering to recommended procedures, K type thermocouples offer accurate temperature measurements.