The petrochemical industry is an essential pillar of the modern industrial world, providing the raw materials that drive countless other industries. Derived from petroleum, these chemicals are key components in everything from plastics to pharmaceuticals, fertilizers to fuels. Understanding the complex processes behind the petrochemical industry is crucial for anyone involved in this influential sector.

This sector is characterized by large-scale operations, intricate processes and stringent safety regulations. It is a challenging environment that demands the highest standards of quality, efficiency, and safety. Therefore, mastering the key elements of the petrochemical industry is essential for maintaining competitiveness and sustainability in this highly demanding market.

The intricacies of the petrochemical industry present various challenges and opportunities. The industry’s continuous expansion and the never-ending demand for its products make it a lucrative field for both large corporations and small enterprises. However, the industry’s complexity and the high costs associated with process failures necessitate a deep understanding of its underlying processes and the instrumentation that allows these processes to be controlled.

What are the basic petrochemical processes?

The basic petrochemical processes involve the conversion of petroleum and natural gas into chemical compounds. These processes include refining, cracking, reforming, and polymerization among others. Each of these processes is complex and requires a high level of precision and control to ensure efficiency and safety.

Refining is the initial process wherein crude oil is converted into useful products such as gasoline, diesel, and jet fuel. Cracking involves the breaking down of heavy hydrocarbon molecules into lighter ones, which are more valuable. Reforming is a process that changes the structure of hydrocarbon molecules to produce higher-value products. Polymerization, on the other hand, involves combining smaller molecules into larger ones to create polymers, which are used in the production of plastics and resins.

In each of these processes, precision and control are paramount. This is where the role of process instrumentation becomes crucial. Without accurate process instrumentation, the safety, efficiency, and productivity of these operations could be compromised.

Understanding Process Instrumentation in the Petrochemical Industry

Process instrumentation is a fundamental component of the petrochemical industry. It involves the use of various instruments and devices to measure and control the physical and chemical properties of substances involved in the petrochemical processes. These properties include pressure, temperature, level, flow, and composition among others.

Process instrumentation enables operators to monitor and control the petrochemical processes accurately and efficiently. It provides real-time data on the process variables, allowing operators to make timely and informed decisions. Furthermore, it helps in maintaining the safety and reliability of the operations by detecting and alerting the operators of any abnormal conditions.

Process instrumentation is not only about measurement and control. It also involves the interpretation and use of the data generated by the instruments. This is where process analytics comes into play. Process analytics involves the use of statistical and mathematical tools to analyze and interpret the data, providing valuable insights into the process performance and efficiency.

Role of Process Monitoring in the Petrochemical Industry

Process monitoring plays a vital role in the petrochemical industry. It involves the continuous observation and recording of the process variables to ensure that the processes are operating within the desired parameters. Process monitoring allows operators to detect and correct any deviations promptly, thereby maximizing efficiency and minimizing waste.

Process monitoring is facilitated by various process instruments, which measure and record the process variables. These instruments include temperature sensors, pressure gauges, flow meters, level indicators, and composition analyzers among others. The data collected by these instruments are displayed and stored for further analysis and decision-making.

Moreover, process monitoring also plays a crucial role in ensuring the safety of the operations. By detecting any abnormal conditions early, it allows operators to take corrective actions immediately, thereby preventing accidents and minimizing the risks associated with the petrochemical processes.

What instruments are used in the petrochemical industry?

The petrochemical industry employs a wide array of instruments for measurement, control, and analysis. These instruments range from simple mechanical devices to sophisticated electronic systems. The choice of instruments depends on the specific requirements of the process, the complexity of the operations, and the safety and environmental regulations.

Temperature sensors, such as thermocouples and resistance temperature detectors (RTDs), are used to measure the temperature of the process fluids. Pressure gauges and transmitters are employed to monitor the pressure in the pipes and vessels. Flow meters, including turbine flow meters and magnetic flow meters, are used to measure the flow rate of the fluids.

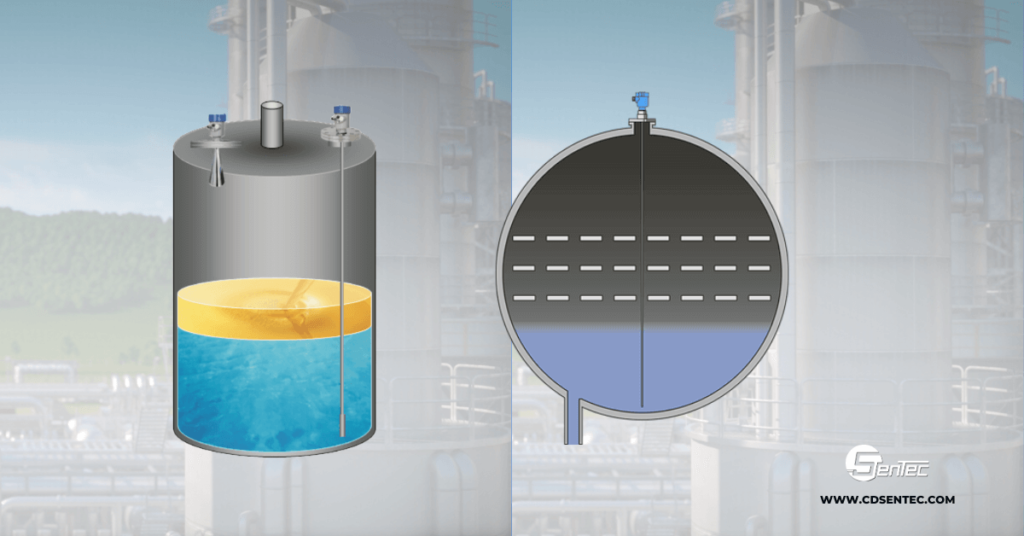

Level indicators and transmitters are used to measure the level of liquids in tanks and vessels. Composition analyzers, such as gas chromatographs and mass spectrometers, are employed to analyze the chemical composition of the process fluids. Additionally, control valves, actuators, and controllers are used to control the flow, pressure, temperature, and level of the process fluids.

The Importance of Instrumentation and Control in Process Monitoring

Instrumentation and control are integral to process monitoring in the petrochemical industry. They enable operators to maintain the desired operating conditions, thereby ensuring the quality of the products, the efficiency of the operations, and the safety of the personnel and the environment.

Instrumentation provides the necessary data on the process variables, which forms the basis for control. Control, on the other hand, involves the manipulation of the process variables to maintain them within the desired range. This is done through the use of control systems, which receive the data from the instruments, process the data, and send commands to the control elements, such as valves and pumps, to adjust the process variables.

Instrumentation and control also play a vital role in process optimization. By providing accurate and timely data on the process variables, they allow operators to identify and correct any inefficiencies, thereby improving the process performance and reducing waste.

Exploring Process Analytics in the Petrochemical Industry

Process analytics is an emerging field in the petrochemical industry, driven by the increasing availability of data and the advancement in data analysis tools. Process analytics involves the use of statistical and mathematical techniques to analyze the process data, with the aim of gaining insights into the process performance, identifying patterns and trends, and predicting future behavior.

Process analytics can be applied in various areas of the petrochemical industry, from process control to quality assurance, from maintenance to safety management. It can help operators to identify the root causes of process deviations, predict equipment failures, optimize process conditions, and improve product quality.

Furthermore, process analytics can enhance the decision-making process. By providing actionable insights, it enables operators to make informed decisions, thereby improving the overall efficiency and profitability of the operations.

How Instrumentation and Control Engineering Enhances the Petrochemical Industry

Instrumentation and control engineering is a specialized field that combines the principles of engineering, physics, and mathematics to design, develop, and maintain the instrumentation and control systems used in the petrochemical industry. Instrumentation and control engineers play a key role in ensuring the safe, efficient, and reliable operation of the petrochemical processes.

Instrumentation and control engineering enhances the petrochemical industry in various ways. First, it provides the necessary tools and technologies to measure and control the process variables, thereby ensuring the quality and consistency of the products. Second, it enables the automation of the processes, reducing human errors and increasing productivity. Third, it facilitates the collection and analysis of process data, providing valuable insights for process optimization and decision-making.

Moreover, instrumentation and control engineering contributes to the safety and sustainability of the petrochemical industry. By enabling the early detection and mitigation of process deviations and equipment failures, it helps to prevent accidents and minimize environmental impact.

The Impact of Process Analyzers and Process Sensors in the Petrochemical Industry

Process analyzers and process sensors are key components of the process instrumentation system in the petrochemical industry. They provide the necessary data on the process variables, which are crucial for process control, quality assurance, and safety management.

Process analyzers, such as gas chromatographs, mass spectrometers, and infrared analyzers, are used to analyze the chemical composition of the process fluids. They provide accurate and detailed information on the concentrations of the different components, which is crucial for maintaining the desired product quality and ensuring the efficiency of the processes.

Process sensors, on the other hand, are used to measure the physical properties of the process fluids, such as temperature, pressure, flow rate, and level. They provide real-time data on these variables, enabling operators to monitor and control the processes accurately and efficiently.

Moreover, process analyzers and process sensors contribute to the safety of the operations. By providing early warning of any abnormal conditions, they allow operators to take corrective actions promptly, thereby preventing accidents and minimizing risks.

Field Instruments and Controls: Their Role in the Petrochemical Industry

Field instruments and controls are essential components of the process instrumentation system in the petrochemical industry. They are installed in the field, close to the process equipment, to measure and control the process variables.

Field instruments include a variety of devices, such as temperature sensors, pressure transmitters, flow meters, level indicators, and composition analyzers. These instruments provide real-time data on the process variables, which are crucial for process control and monitoring.

Field controls, on the other hand, include control valves, actuators, and controllers. These devices receive commands from the control system and adjust the process variables accordingly. They play a key role in maintaining the desired operating conditions and ensuring the safety and reliability of the operations.

Moreover, field instruments and controls are often designed to withstand harsh operating conditions, such as high temperatures, high pressures, corrosive environments, and explosive atmospheres. This makes them reliable and durable, ensuring their long-term performance and reducing maintenance costs.

Process Control Instruments: Maximizing Efficiency in the Petrochemical Industry

Process control instruments are indispensable for maximizing efficiency in the petrochemical industry. They enable operators to maintain the process variables within the desired range, thereby ensuring the quality of the products, the efficiency of the operations, and the safety of the personnel and the environment.

Process control instruments include a variety of devices, such as temperature controllers, pressure regulators, flow controllers, and level controllers. These devices receive signals from the process sensors, compare them with the set points, and adjust the process variables accordingly.

Moreover, process control instruments are often integrated with advanced control systems, such as programmable logic controllers (PLCs), distributed control systems (DCSs), and supervisory control and data acquisition (SCADA) systems. These systems provide sophisticated control algorithms and user-friendly interfaces, enhancing the accuracy and efficiency of the process control.

Instrument Automation in the Petrochemical Industry

Instrument automation is a rapidly growing trend in the petrochemical industry. It involves the use of computerized systems to automate the measurement and control of the process variables. Instrument automation can enhance the efficiency, reliability, and safety of the petrochemical processes.

Instrument automation can be applied in various areas of the petrochemical industry. In process control, it can automate the adjustment of the process variables, reducing manual interventions and human errors. In process monitoring, it can automate the collection, storage, and analysis of the process data, enabling real-time decision-making and process optimization.

Furthermore, instrument automation can integrate the various process instruments and control systems, creating a unified and coordinated process control and monitoring system. This can simplify the operations, improve data visibility, and facilitate remote monitoring and control.

Conclusion: The Future of Instrumentation in the Petrochemical Industry

The future of instrumentation in the petrochemical industry is promising, driven by the advancements in technology and the increasing demand for efficiency, quality, and safety. As the industry continues to evolve, so will the role of process instrumentation.

Emerging technologies, such as wireless sensors, smart instruments, and digital twins, are expected to revolutionize the field of process instrumentation. These technologies can enhance the accuracy, reliability, and functionality of the process instruments, providing new opportunities for process control, monitoring, and optimization.

Furthermore, the integration of process instrumentation with advanced data analytics and artificial intelligence can unlock new potentials for process optimization and decision-making. By turning the process data into actionable insights, these technologies can help operators to maximize efficiency, reduce waste, and ensure the sustainability of the petrochemical industry.

In conclusion, mastering process instrumentation is essential for anyone involved in the petrochemical industry. With its crucial role in process control, monitoring, and optimization, process instrumentation is indeed the backbone of the petrochemical industry. As the industry navigates the challenges and opportunities of the future, the need for skilled and knowledgeable process instrumentation professionals will only continue to grow.