What Is Radar level transmitters ?

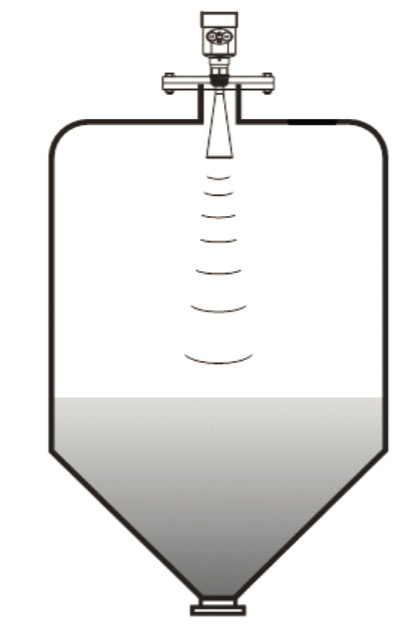

Radar level transmitters use radar technology to perform non-contact continuous level measurement. The radar level indicator converts the level into an electrical signal. The level signal output can then be utilised by other instrumentation to monitor or control. Liquids and solids are commonly measured with this measuring technique. Like: Fly ash silo. Radar level sensors are divided into: Pulsed radar technology and frequency modulated continuous wave (FMCW) radar level sensors.

RADAR LEVEL SENSOR WORKING PRINCIPLE

The radar level antenna emits narrow microwave pulses, which are transmitted downward through the antenna. After the pulse touches the surface of the measured medium, it is reflected back and received by the antenna system again. The signal is transmitted to the electronic circuit part and automatically converted into a level signal (because the pulse travels very fast, the electromagnetic wave reaches the target and returns to the receiver after reflection – The time it takes to go back and forth is almost instantaneous).

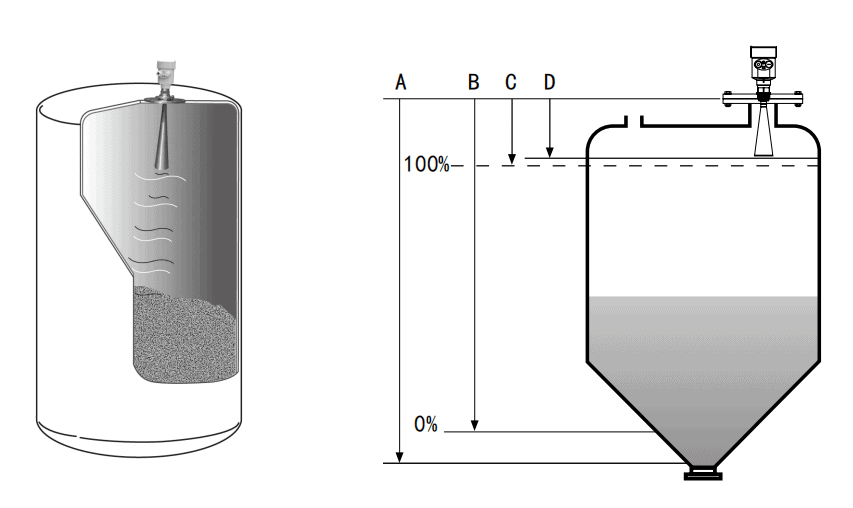

A-Range setting

B-Low adjustment

C-high adjustment

D-Blind zone range

The reference plane of the measurement is: The bottom surface of the thread or the sealing surface of the flange

Note: When using radar level timing, make sure that the highest material level cannot enter the blind area of the measurement (the area shown in D in the figure).

What are the features of Radar Level transmitter?

1. No blind spot, high precision

2. Two-wire technology is an excellent substitute for differential pressure instruments, magnetostrictive, radio frequency admittance, and magnetic flap instruments.

3. Not affected by pressure changes, vacuum, temperature changes, inert gases, smoke, steam and other environments

4. Easy to install, firm and durable, maintenance-free

5. The output signal is 4mA ~ 20mA or according to the HART protocol, the calibration is simple, the on-site calibration operation can be easily realized through the digital LCD display, and the simple configuration setting and programming can be realized through the software

6. The measurement is sensitive and the refresh speed is fast.

7. It is suitable for high temperature working conditions, up to 200 ℃ process temperature. When using high temperature extended antenna, it can reach the guided wave type. Scope and characteristics: Guided wave microwave level instrument is used to measure the dielectric constant of liquids, slurries and granular materials. Contact continuous measurement of relatively small media, suitable for occasions where temperature, pressure changes, and inert gas or steam exists.

Types of radar level transmitters

Generally speaking, we have the following two division methods for the types of radar level sensors.

- There are two types of radar level sensor: contact and non-contact.

Also known as: Noninvasive or Invasive.

The non-contact type includes pulse radar and continuous frequency modulation. The probe is usually a horn antenna, that is, a tubular antenna, but the diameter of the horn is different, and the length of the horn is different. So it looks like some speakers, and some look like tubes, but they are actually one.

In addition, the contact radar is equipped with a rod antenna, usually called a guided wave radar, which is a pulse radar in principle. You can also learn more about guided wave radar level sensors. - In principle, radar level sensors can be divided into three main types: Pulsed. Frequency modulated continuous wave. And guided wave radar.

Non-contact radar is called a radar level sensor, which includes two types of rod antenna and horn.The contact radar level gauge can also be called a guided wave radar level gauge. Including single rod type and single cable type, double cable type, coaxial type, etc., which includes high-frequency and low-frequency radar level gauge.

Radar VS GWR Guided Wave Radar

Guided wave radar level sensor working principle

The guided wave radar level sensor is a measuring instrument based on the principle of time travel. The radar wave runs at the speed of light. The running time can be converted into a level signal by electronic components. The probe sends out high-frequency pulses and propagates along the cable probe. When the pulse meets the surface of the material, it is reflected back and received by the receiver in the instrument. The distance signal is converted into a level signal.

Is there any difference between pulse radar and GWR radar level meter?

1. Different ways of contact:

Radar level gauges are non-contact. Guided wave level gauges are contact-type. That is to say, the guided wave type cannot be used in the occasions where food grade requirements are high.

2. The working medium is different: Guided wave radar level gauges also need to consider the corrosiveness and adhesion of the medium. Moreover, the installation and maintenance of guided wave radars that are too long are more difficult. In the case of low dielectric constant, the measurement principle of radar or guided wave radar is based on the difference in dielectric constant. Since the waves emitted by ordinary radar are divergent, when the dielectric constant is too low, the signal is too weak to measure. Stable. The guided wave radar wave propagates along the probe. The signal is relatively stable. In addition, the general guided wave radar also has a bottom detection function, which can be corrected according to the measured value of the bottom echo signal to make the signal more stable and accurate.

3. Model types Selection is different: Ordinary radars can be used interchangeably. Guided wave radars cannot be used interchangeably due to the fixed length of the probe (cable) according to the original working conditions. The selection of guided wave radars is more troublesome than ordinary radars.

4. Different measuring ranges: Ordinary radar is more commonly used on 30 and 40m tanks, and can even measure 150m. Guided wave radar also needs to consider the force of the probe (cable). It is also because of the force that the measurement distance of the guided wave radar is generally not very long. However, the guided wave radar has obvious advantages in some special working conditions, such as stirring in the tank and large medium fluctuations. The measured value of the guided wave radar fixed at the bottom of such working conditions is more stable than that of the flexible radar. There are also small tanks. For level measurement, due to the small installation measurement space (or many interferences in the tank), general radar is not suitable, and the advantages of guided wave radar are revealed at this time.

What are the main advantages of radar level measurement?

1. Strong versatility: It can measure liquid level and material level, and can meet the measurement requirements of different temperatures, pressures and media. The maximum measurement temperature can reach 800 °C, and the maximum pressure can reach 5MPa. It can be used in harsh occasions such as corrosion and impact. .

2. Anti-hanging material: The unique circuit design and sensor structure make the measurement not affected by the sensor hanging material, no need for regular cleaning, and avoid wrong measurement.

3. Maintenance-free: There are no moving parts in the measurement process, there is no damage to mechanical parts, and no maintenance is required.

4 Anti-interference: contact measurement, strong anti-interference ability, can overcome the influence of steam, foam and stirring on the measurement.

5. Accurate and reliable: the measurement quantity is diversified, making the measurement more accurate, the measurement is not affected by environmental changes, the stability is high, and the service life is long. Technical Parameters Rod Pulse Type Barrel Pulse Type Cable Type Waveguide Type Coaxial Waveguide Maximum Range: 20M 70M 35M 6M Process Connection: Thread, Flange Flange Thread, Flange Flange Frequency Range: 8.4GHZ 10GHZ 8.4GHZ 10GHZ Output signal: 4-20mA/HART two-wire Profibus PA Communication interface: HART Power supply: 24V DC(+/-10%)

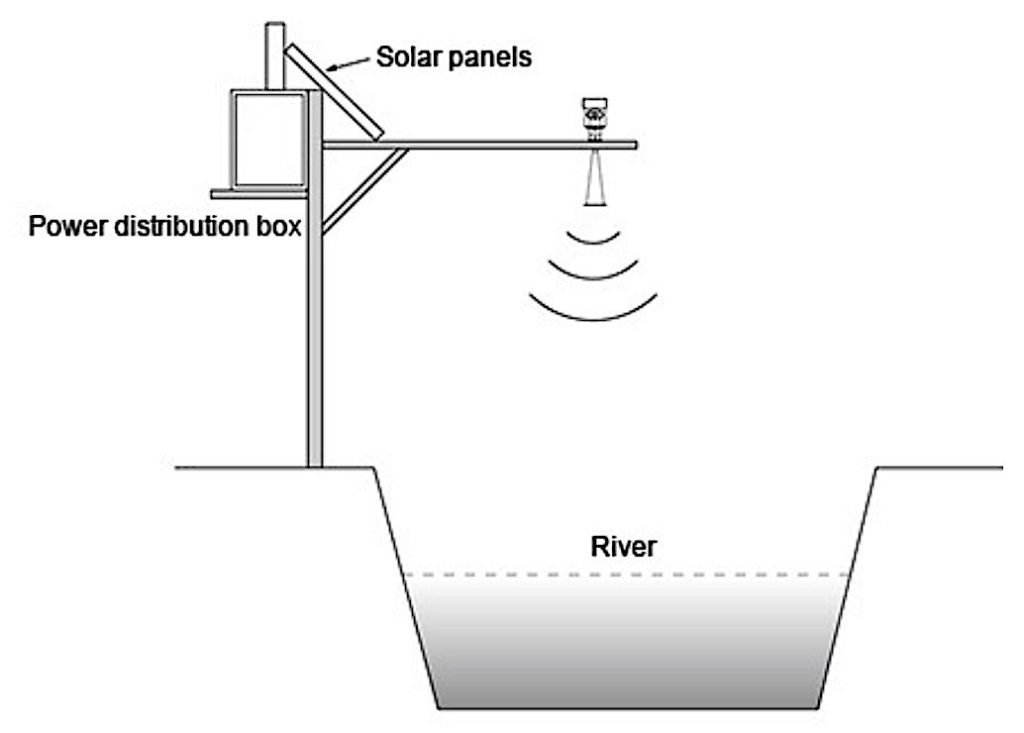

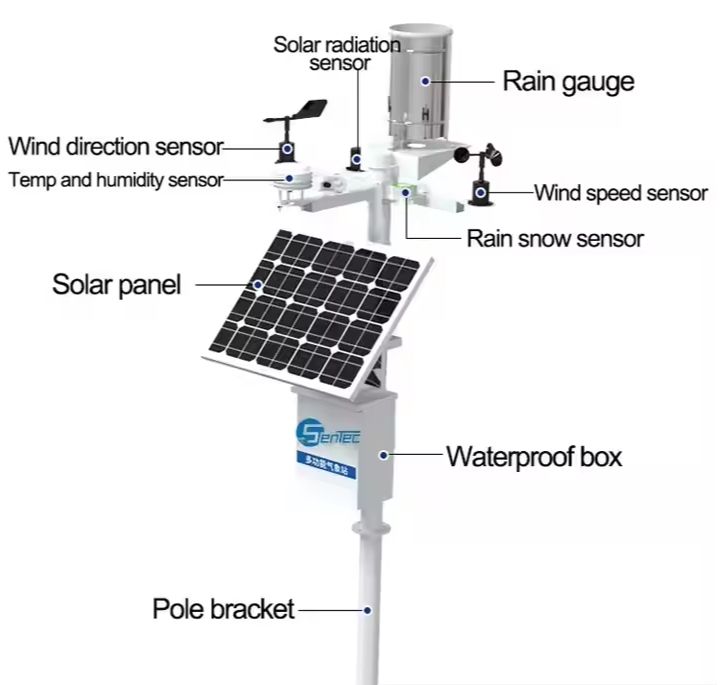

RADAR LEVEL TRANSMITTER APPLICATION

The radar sensors of the SRL series are used for non-contact level measurement of liquids and solids. Even under high pressure and extreme temperature, they can measure various media. Radar sensors can be used for simple measurements or for measuring corrosive media. They are also suitable for applications with high hygiene requirements. These sensors can measure light and heavy solid materials with absolute reliability, even if the dust and noise are strong, they are not affected by adhesions or condensate.