- Tel: +86 28 87436908

- Email: info@cdsentec.com

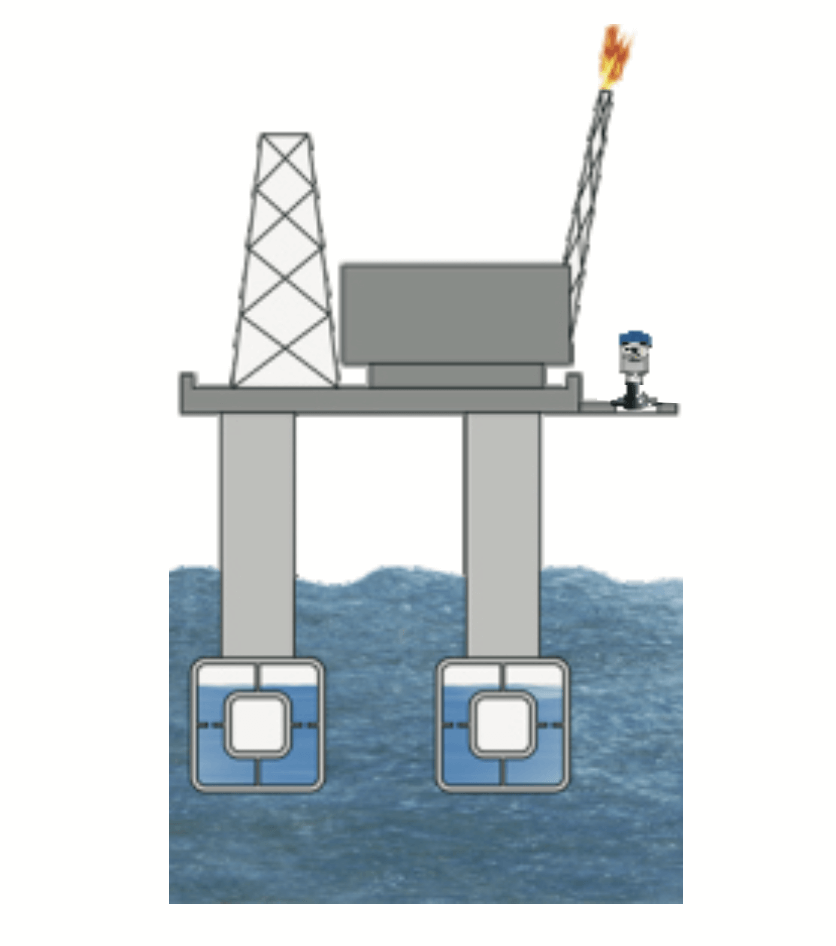

Offshore oil and gas process instrumentation plays a crucial role in controlling and monitoring various variables in offshore facilities. This includes temperature, pressure, and fluid levels, which are essential for ensuring the safety and efficiency of operations.

Drilling and pumping platforms in the offshore oil and gas petrochemical industry are equipped with a range of process instrumentation to ensure safe and efficient operations

The height of floating drilling or pumping assets like platforms or FPSOs must be precisely maintained, even in the roughest seas with waves up to 30 m high. Environmental influences such as wind and waves must be measured quickly and accurately, then evaluated with GPS navigation data. Furthermore, quick and exact measurement of wave heights is needed should there be an evacuation, where “freefall lifeboats” need to be released to meet waves at their highest point.

Floating drilling or pumping assets such as platforms or FPSOs are stabilized by filling or emptying ballast tanks with seawater. This enables operators to critically and safely manage the ballast and trim of a vessel according to operational needs, deck loading and sea conditions. For trouble-free operation of the ballast system and the safety of personnel and equipment on board, reliable level measurement and point level detection are absolutely essential.

Rain run-off on board of oil platforms and ships is polluted with production residues and contaminants such as oil, sand and dirt. The rainwater with these contaminants must be collected in special tanks and properly disposed of. A reliable level measurement in the tank protects against overflow of the open drain removing the possibility of subsequent marine pollution.

Process instrumentation plays a crucial role in controlling and monitoring variables like temperature, pressure, fluid levels, and emissions. It enables real-time measurement and control, optimizing processes for maximum productivity and resource efficiency.

Offshore distillation is a widely used process in the oil and gas industry for separating various components of a mixture based on their boiling points. It is a crucial step in refining crude oil into different fractions, such as gasoline, diesel, and jet fuel.

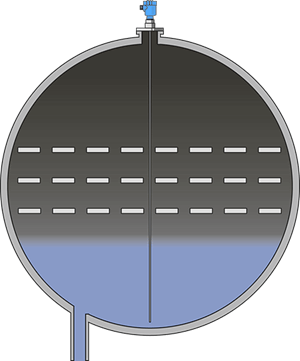

It is important that a desalter unit runs efficiently to prevent corrosion to downstream equipment. When the crude oil mixes with the emulsifying chemicals and water, the resulting emulsion layer makes it difficult for standard level measurement technologies to reliably track the interface. Radiation-based measuring instruments are not affected by this and allow to track the interface even with thick emulsion layers present in the tank to make sure that the desalting process can be controlled efficiently at maximum throughput.

To maximize efficiency of the electrostatic grid as it removes contaminants within second and third stage desalters, a crucial point of control is to maintain the oil and water interface just below this grid. Reliable measurement of this level protects the grid from shorting out on the water as well as increasing efficiency of the unit, which ensures the quality of the feed moving into the next process unit.

Offshore distillation process instrumentation can maintain optimal conditions within the distillation process, resulting in improved productivity and product quality. Sentec is a trusted provider of process instrumentation solutions for offshore oil and gas applications

Offshore drilling operations involve the use of specially engineered drilling mud, also known as drilling fluid, which serves several crucial purposes. The composition and properties of offshore mud are meticulously designed to meet the specific challenges faced in offshore environments.

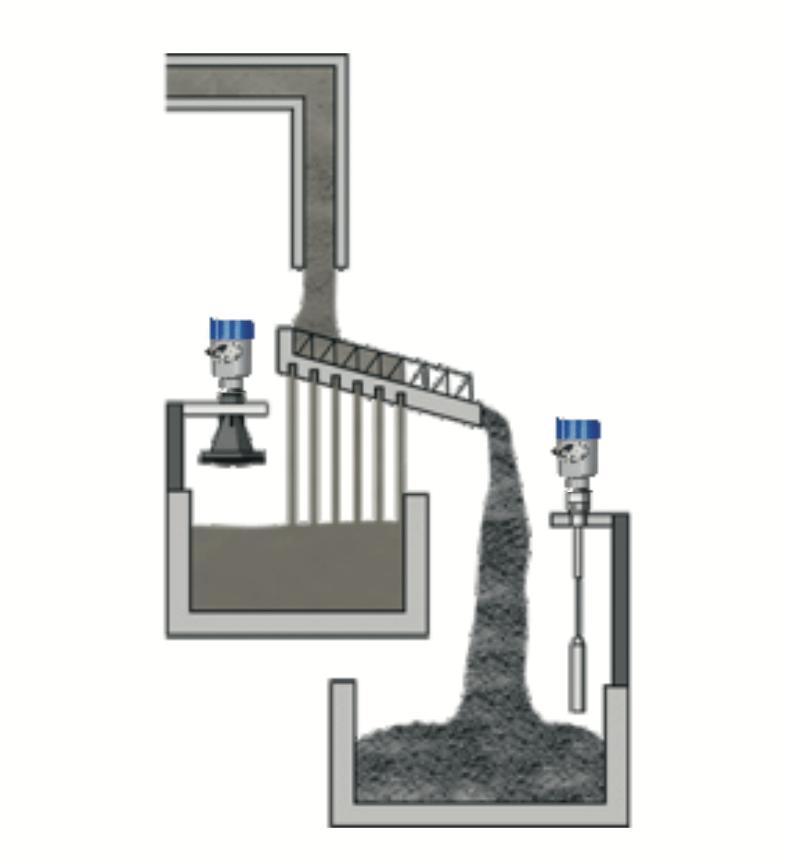

Prior to, and during pumping into the well, the density of the mud needs continuous monitoring. Density is an important criteria for determining the correct composition of the drilling mud. The correct mud formulation ensures smooth forward propulsion, wear-free drilling and excellent sealing of the borehole is ensured through density monitoring.

Through the effects of strong vibration in the shaker, the liquid and solid components of the drilling mud returning from the borehole are separated from each other. The drilled rock and the sand are disposed of and the valuable drilling mud is fed back into the continuous drilling process. Level measurement and point level detection are absolutely necessary for effective processing of the drilling mud in the shaker.

he drilling mud flowing back from the drilling contains large amounts of solids. To avoid clogging in these pipes and the associated damage to the drill head and loss of production, a reliable monitoring of the entire mud return system is essential.

The drilling mud flowing back under high pressure from the drilling well is held and monitored in the trip tank. This drilling mud is contaminated with sea water, rocks and sand. In addition to materials like rocks and sand, residues of oil and gas are also present. The built-in level measuring system provides feedback about down-well conditions, basic data for comparing the quantity of drilling mud fed into the wellbore with that returned, as well as regulating mud production.

Offshore mud process instrumentation play a crucial role in monitoring and maintaining the drilling fluid system, ensuring its effectiveness in cooling and lubricating the drill bit, removing debris, controlling formation pressures, and maintaining wellbore stability.

Offshore oil and gas extraction refers to the process of extracting oil and natural gas reserves found in the ocean area. The world's oceans contain vast reserves of oil and gas, which are accessed through offshore drilling.

The hydraulic oil used to transmit power circulates in a closed system. There is also loss of hydraulic oil as the power unit needs to be lubricated and leaks can occur. In order to ensure the normal operation of the hydraulic system, it is necessary to monitor the oil level of all hydraulic oil tanks.

The mixture collected from the production well contains crude oil, gas, water and sand, which need to be separated by an oil-water separator. Accurate liquid level and pressure measurement in the oil-water separator can maximize the utilization of the separator and improve the efficiency of the entire oil recovery facility. Accurate interfacial measurements are critical to the quality of the oil because the components are separated by gravity settling according to their different densities.

The unprocessable gaseous residues from the produced oil and gas are collected in the flare drum and liquefied at high pressure of +100 bar. The condensed liquid settles on the bottom of the tank, waiting for further treatment. The unliquefied gas is burned under reduced pressure in the flare system. Reliable level measurement is essential to keep processes running efficiently and safely.

The extracted natural gas and tail gas produced by oil extraction contain moisture, which needs to be collected in a gas-water separator (scrubber) for separation. The high pressure of +150 bar inside the tank liquefies the gas. Accurate pressure and liquid level measurement can maximize the utilization of the gas-liquid separator and effectively control the gas dehydration process. For gas dehydration, the water needs to be combined with glycol followed by mechanical separation. At this time, accurate measurement of the interface has a crucial impact on the quality of the gas.

Process instrumentation in the oil and gas industry plays a crucial role in the control and monitoring of various parameters in offshore drilling and extraction operations. This includes measuring and controlling temperature, pressure, fluid levels, gas emissions, and other process variables.

SenTec online resource library is a place you can know more knowledge from video, cases study, e-book etc.