Paper making process instruments and solutions

In the paper making process, various instruments and solutions are used to ensure efficiency and accuracy. These instruments play a crucial role in optimizing control and improving production capacity while reducing costs. SenTec is a company that offers a comprehensive range of process measurement and control products specifically designed for the pulp and paper industry.

Table of Contents

Background: Process control instruments for pulp and paper industry

The pulp and paper industry relies on process control instruments to optimize production and ensure high-quality output. Companies like Yokogawa and SenTec offer a range of solutions specifically designed for pulp and paper industry.

SenTec specializes in instrumentation for the paper and pulp industries. These measurement and control solutions include temperature, gas levels, pH, conductivity, density, flow, pressure etc.

These instruments play a crucial role in monitoring and controlling various processes in the pulp and paper plant, such as monitoring filtrate liquor, bleaching filtrate, pulp slurry flow, adhesive fluid measurement, pressure control, and density control.

SenTec provides sensors and controllers that can withstand harsh process conditions and environments, such as corrosive chemicals and high temperatures. These instruments offer stable and accurate measurement, supporting higher quality production control. SenTec also offers predictive diagnostics for predictive maintenance, ensuring safe and reliable plant operation.

Paper making process instruments solutions: Pressure sensors and transmitters

In the paper industry, pressure sensors and transmitters are commonly employed to monitor and control the pressure levels in different sections of the production line. They help maintain optimal pressure conditions, which are essential for achieving desired paper quality and preventing any potential damage or disruptions.

Application scenarios of pressure sensors and transmitter in paper making process

Pressure measurement in the pressure screen

Pressure screens are used to filter out impurities and separate fibres in stock preparation. Efficient screening requires a controlled pressure difference between inlet and outlet, which therefore requires continuous, reliable measurement.

Pressure measurement on the refiner

Refiners are used in paper production to grind up pulp. The pressures at the input and output have to be measured for monitoring the loading and release of the grinding set as well as for display of performance.

Pressure measurement in the headbox

The paper suspension is pumped into the headbox of the paper machine. The outflow speed of the suspension is adjusted to match the speed of the screen by adjusting the pressure of the headbox feed pump. This means an accurate pressure measurement, with minimal turbulence created in the headbox.

Differential pressure measurement in the drying cylinder

The residual moisture content of the paper web is removed by steam-heated cylinders in the drying section of the paper machine. The correct level of heat transfer from the drying cylinder to the paper is monitored by pressure measurements both at the inlet and at the outlet.

SenTec offers a range of pressure sensors and transmitters specifically designed for the paper making process in the pulp and paper industry. These pressure instruments are used to measure the pressure or level of industrial liquids and gases and transmit the output to a control system. SenTec manufactures pressure transmitters for gauge pressure, differential pressure, absolute pressure, liquid level, mass flow, multi-variable sensing, draft pressure, low flow, and hygienic applications.

These instruments play a crucial role in monitoring and controlling various processes in the paper making plant, ensuring efficient and high-quality production for harsh environments and deliver high integrity process measurements.

Paper making process instruments solutions: Level sensors and switches

In paper making process, level sensors and switches are essential components in the papermaking process. They are used for various functions such as level sensing, alarms, leak detection, overfill shutoff, and regulating the interface between different levels. These sensors help in improving efficiency throughout the manufacturing process. By accurately measuring the levels of liquids and materials, they ensure optimal conditions for pulp preparation, preventing overflow or underflow situations. Level switches are particularly useful in detecting high or low levels and triggering alarms or automatic shut-off systems to prevent damage or disruptions.

Application scenarios of level sensors and switches in paper making process

Level measurement and point level detection in the bleaching tower

In order to achieve the desired degree of whiteness, the pulp must be bleached. The bleached pulp is discharged via screw conveyors. Due to its size, the bleaching tower is never emptied. Continuous level measurement enables a smooth process flow.

Level measurement in the deaerator

The approach flow system connects the stock preparation facility with the paper machine. Here, the pulp for the paper machine is diluted to the required consistency. For effective performance, the PMD3051 level transmitter can help the stock deaerator always to be filled to a predefined, millimetre-exact level.

Measuring liquid level in discharge chute

The fiber suspension obtained in the pulper is discharged into a discharge chute. The capacity for the next emptying or subsequent processing step is determined by measuring the liquid level in the discharge chute.

Level measurement in starch silos

Starch is an important additive to increase the strength of the paper. For optimal control of the silo filling process, a reliable level measurement is required. To prevent the eccentric pump from running dry, an in-line switch is needed upstream of the pump.

As a earliest level sensors and switches manufacturer for the paper making process, SenTec provides a range of level sensors and switches specifically designed for the pulp and paper industry. These instruments play a crucial role in monitoring and controlling the level of various liquids and materials used in the paper making process. A variety of level sensors and switches manufactured that are suitable for the harsh conditions and environments often found in pulp and paper plants.

These level sensors and switches are essential for maintaining efficient and high-quality production in the paper making process. These instruments help ensure that the right amount of materials are used, prevent overflows or spills, and contribute to the overall control and optimization of the production process.

Subscribe To get new products and solutions

Paper making process instruments solutions: Flow meter and density meter

When it comes to instrumentation solutions for the paper-making process, flow meters and density meters play a crucial role. Flow meters and density meters contribute to precise control and efficiency throughout the papermaking process by accurately measuring flow rates and concentrations of additives.

Application scenarios of flow meter and density meter in paper making process

Flow measurement in the hydraulic oil station

In the press section of a paper machine, very high pressures are needed for dewatering the stock. Hydraulic oil stations integrated pumps provide oil to the required locations and to enable fully automatic operation of the station, the flow rate in the supply tanks must be measured.

Measuring Flow in Steam Pipelines

Water vapor is required in the drying section of the paper machine. Flow rates are determined using orifice plates with built-in differential pressure transmitters to ensure optimal consumption and demand planning.

Density measurement in liquor recovery

The black liquor resulting from pulp cooking is regenerated and fed back into the digester.Density measurement of the liquor in the pipelines is required for eco-friendly and energy-efficient process control.

Flow meters, such as the electromagnetic flow meter, accurately measure the flow rate of liquids and slurries in pipes. This is important for ensuring the correct chemical treatment, proper bleaching, and consistency of the paper. The electromagnetic flow meter generates a magnetic field that induces an electrical voltage proportional to the fluid’s flow rate, making it highly accurate and reliable.

Density meters, on the other hand, measure the density of liquids and are used to monitor and control the density of various materials in the paper-making process. These instruments are essential for maintaining efficient and high-quality production, ensuring the right amount of materials are used and preventing overflows or spills.

SenTec offer a range of instruments specifically designed for the paper and pulp industries, including flow meters and density meters.

Paper making process instruments solutions: temperature sensor and controller

Temperature sensors and controllers play a crucial role in the paper-making process by ensuring optimal temperature conditions for various stages. These instruments help monitor and control temperature levels accurately, leading to improved product quality and operational efficiency.

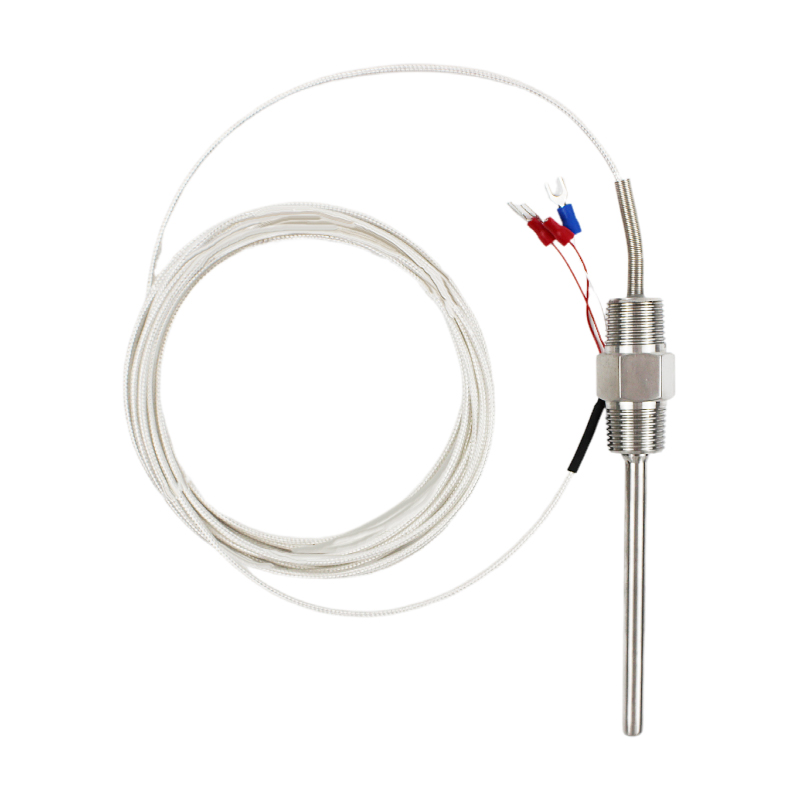

Temperature sensors, such as thermocouples or resistance temperature detectors (RTDs), are used to measure the temperature at different points in the paper-making process. They provide real-time data that allows operators to monitor temperature variations and make necessary adjustments. This ensures that the process operates within the desired temperature range, preventing any deviations that could negatively impact the final product.

Temperature controllers, on the other hand, are responsible for maintaining the desired temperature levels by regulating the heating or cooling systems. They receive inputs from the temperature sensors and adjust the equipment accordingly to achieve and maintain the set temperature. This precise control prevents overheating or underheating, which can affect the quality and consistency of the paper being produced.

SenTec offers accurate and reliable temperature measurement and control in providing instrumentation solutions for the paper and pulp industry.

Subscribe To get new products and solutions

Latest Posts

Dissolved Oxygen Sensor Selection: Proven Tips for Better Water Monitoring Results

Underwater Ultrasonic Sensors: Essential Guide for Real Projects