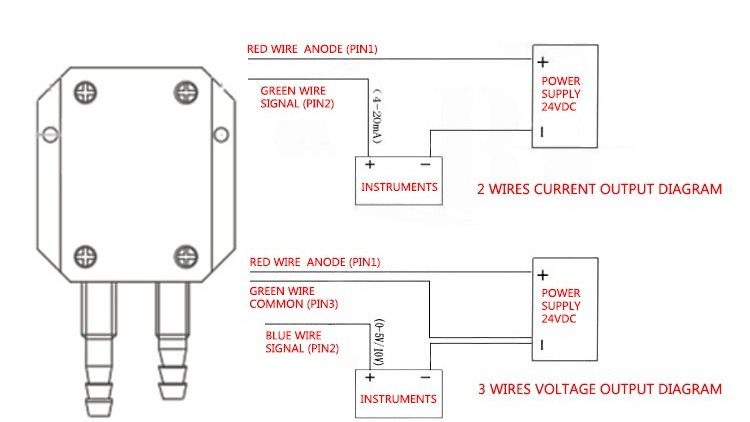

Micro pressure differential sensor adopts imported high-precision, high-stability micro-pressure sensitive chips, and undergoes strict and precise signal processing such as temperature compensation, linear compensation, signal amplification, V/I1 conversion, reverse polarity protection, pressure overload current limiting, etc. Reliably convert very small differential pressure, wind pressure, flow and other parameters into industrial standard 4~20mA or 0~10mA signal output.

Pressure differential sensor working principle

The differential pressure sensor is the most commonly used sensor in industrial practice, also known as the wind pressure sensor. The working principle of the wind pressure sensor is that the pressure of the wind pressure sensor acts directly on the diaphragm of the sensor, causing the diaphragm to produce a micro-displacement proportional to the pressure of the medium, changing the resistance of the sensor, and detecting this change with an electronic circuit. And convert and output a standard signal corresponding to this pressure.

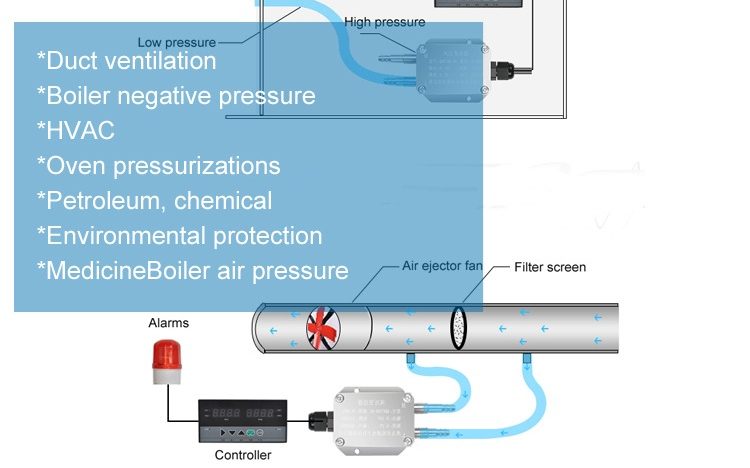

Micro differential pressure transmitter application

The wind pressure sensor is the most commonly used sensor in industrial practice. It is widely used in various industrial automation environments, including boiler air supply, dust removal equipment, water conservancy and hydropower, railway transportation, intelligent buildings, production automation, aerospace, military, petrochemical, oil wells, electric power, ships, machine tools, pipelines and many other industries.