What is a pressure switches ?

A pressure switch is an electrical contact device that drives a switch by the action of gas or liquid pressure.Read our pressure switch symbol article for more information.

Pressureswitch Working principle

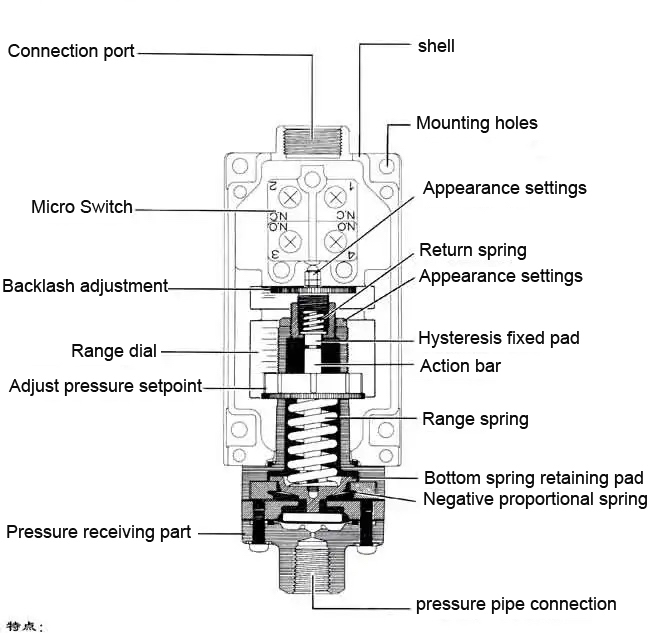

The working principle of the press-switch: When the driving pressure of the external gas or liquid can overcome the elastic force of the compression spring, the power element pushes the piston top rod upward. Resulting in the action of the micro switch (that is NO/NC, pressure switch stuck open and pressure switch stuck closed) to control the circuit breakage. When the external pressure disappears or the pressure is low, the piston is separated from the micro switch under the action of the spring, and the contact system is reset.

To realize specific control point, you can set with low pressure switch and high pressure switch.

Structure of the Pressure switch

The preasure switch is mainly composed of power or pressure sensitive elements (feeling external pressure), mechanical linkage (transmitting pressure), microswitch (executed by normally open and normally closed contacts) and other parts. Read more for parts of pressure swtich.

Switch Protection: Bottom spring retaining pads limit the travel of the action lever. Even if there is strong pressure, it will not break the power steering pressure switch

Pressure receiving part: the low pressure part adopts diaphragm and bellows type, and the high pressure adopts piston type.

Diaphragm type: The durability of the diaphragm is considered.

Piston: O-ring seal.

Bellows: good adaptability to pressure media. Low temperature, high temperature resistance, good temperature characteristics. The change with time is small. If the medium is not corrosive, the change of time to the pressure switch can be ignored.

Pressure switch adjustment: The minimum pressure value that makes the pressure switch act is called the rated value of the pressure switch, and its size can be adjusted by screws according to the actual use of the controlled object to meet the needs of different requirements and occasions.

Pressure switch types

Pressure switch can divide into mechanical pressure switch and ElectronicPressure Switch

Mechanical (Electromechanical) Pressure Switches

Mechanical pressure switch, the micro switch action is caused by pure mechanical deformation. When the pressure increases, the different sensing pressure components (diaphragms, bellows, pistons) will be deformed and will move upwards. Through mechanical structures such as railing springs, the uppermost micro switch is finally activated to output electrical signals.

Mechanical pressure switch types: Piston Pressure Switch, Bourdon Tube Pressure Switch, Diaphragm Pressure Switch,Differential Pressure Switch

Electronic Pressure Switch

The electronic digital pressure switch has a built-in precision pressure sensor, amplifies the pressure signal through a high-precision instrumentation amplifier, and collects and processes data through a high-speed MCU. Generally, 4-digit LED real-time digital pressure display is used, relay signal output, and upper and lower limit control points can be freely set , small hysteresis, anti-vibration, fast response, stable and reliable, high precision (accuracy is generally ±0.5%F.S, high is ±0.2%F.S), the use of hysteresis settings can effectively protect the repeated actions caused by pressure fluctuations, protection control The equipment is a high-precision equipment that detects pressure and liquid level signals and realizes pressure and liquid level monitoring and control.

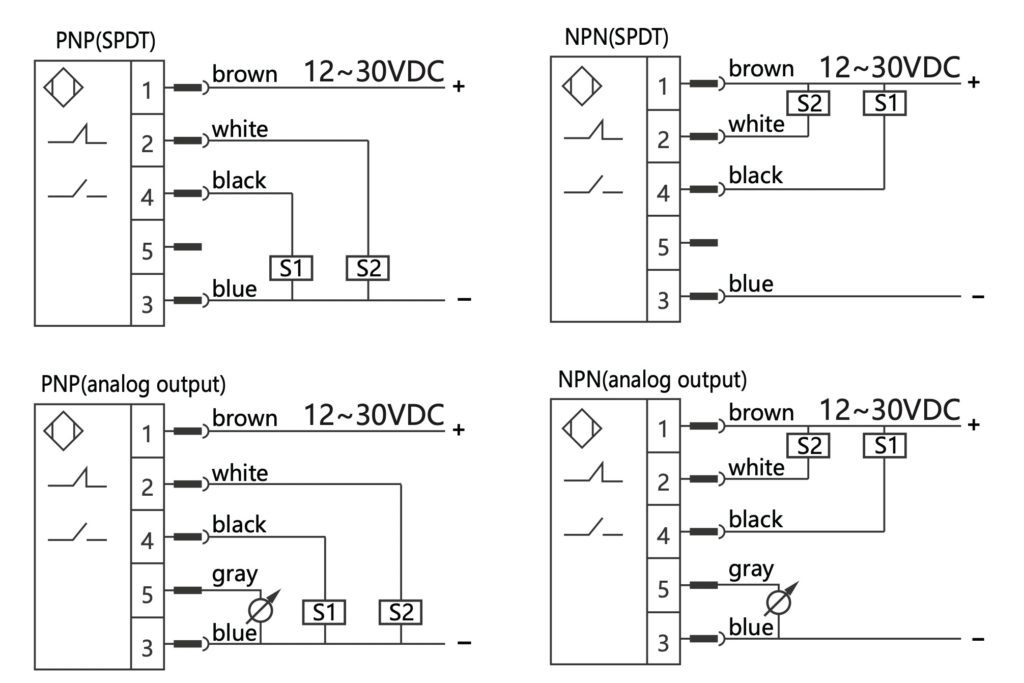

Pressure Switch wiring

Typical pressure switch wiring diagram as follows:

Pressure Switch Selection Criteria

Accuracy: A value indicating the precision of the device, including linearity, tolerance, hysteresis, repeatability, etc.

Maximum pressure (Max.P): The maximum value of the pressure range.

Full Scale (F.S): The difference between the maximum and minimum values of the pressure range.

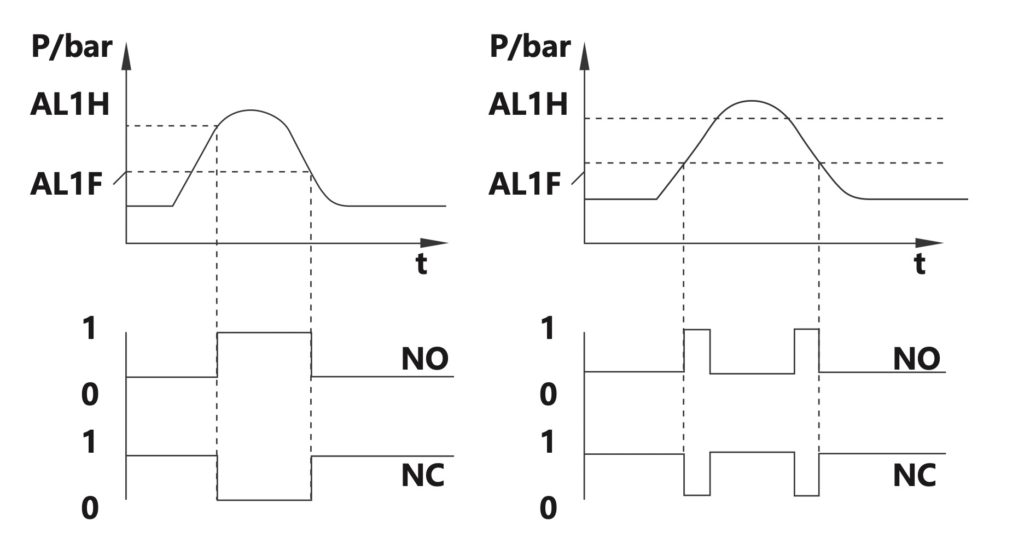

Connection difference (dead zone): refers to the difference between the set action value and the reset value of the switch. For example, when the set value is 1MPa and the actual reset value is 0.9MPa, the connection difference is 0.1MPa.

Working temperature: refers to the temperature range in which the internal mechanism and sensitive components of the instrument will not be continuously deformed when working. Generally, the recommended working temperature range of the pressure switch is -5~400C. If the temperature of the medium is too high, you can consider adding an accessory siphon (filling) to achieve the purpose of cooling.

S.P.D.T (single pole double throw): consists of a normally open, a normally closed contact and a common terminal.

D.P.D.T (Double Pole Double Throw): It consists of a symmetrical left and right common terminals and two groups of normally open and normally closed terminals.

Upper limit one contact (normally open): When the pressure rises to the set value, the contact will act and the circuit will be turned on.

Lower limit one contact (normally closed): When the pressure drops to the set value, the contact will act and the circuit will be turned on.

Upper and lower limit two-contact HL: It is a combination of upper limit type and lower limit type. It is divided into two types of independent action of two contacts (double setting, double loop) and simultaneous action of two contacts (single setting, double loop).

Upper limit 2 contacts: Combines two upper limit forms, which are divided into two types of independent action of two contacts (double setting, double loop) and two types of simultaneous action of two contacts (single setting, double loop).

Lower limit 2 contacts: Combines two lower limit forms, which are divided into two types of independent action of two contacts (double setting, double loop) and two types of simultaneous action of two contacts (single setting, double loop).

Pressure Resistance: The maximum pressure that a pressure switch can withstand to maintain its normal performance. However, when the pressure switch is used in an overpressure situation, the sensitive element will be continuously deformed, and the pressure setting value will change at this time, and the pressure switch will not be able to perform its normal performance and may even be damaged.

IP (Protection Rating): It is a standard drafted by the International Electrotechnical Institute (IEC) about the dust and moisture resistance of lamps.

Pressure Switch application

Water Pumping pressure switch Systems:

This may be the most common use of pressure switches. Pressure switches are used in water pumps to cut-in power into the motor which drives the pump in case of low level or low line pressure. Well water pressure switch upon reaching the set pressure, power is cut-out.

Compressed Air pressure switch Systems:

This is similar to transmission fluid pressure switch. Pressure switches are used to cut-in power to the compressor motor when low pressure is detected. This maintains the pressure of the compressed air system. If for negative pressure, it should used vacuum pressure switch.

Pneumatic and Hydraulic pressure switch Systems: These are control systems that use pneumatic and hydraulic actuators. Pumps and compressors maintain reservoir pressure and level through Hvac pressure switch or oil pressure switches

Air Conditioning and Refrigeration pressure switch system: In a refrigeration system, the thermostat provides the controlling feedback signal. However, in case there is a problem in the system, the thermostat will only sense the temperature in the cooled space but not the state of the equipment. A pressure switch serves as a safeguard that trips the compressor motor in case of overpressure. Another use of a pneumatic pressure switch in a refrigeration system is protection on the low-pressure side which indicates a possible refrigerant leak.

Furnace and Boiler Systems:The pressure switch in a furnace or boiler serves as a safety interlock to prevent the igniter from operating in case there is a problem with the draft system. This prevents the combustion chamber from operating which can result in incomplete combustion.

Filtering and Screening Equipment:A differential pressure switch is used to measure or monitor the pressure drop across filters and screens. The pressure switch triggers an alarm or notification to indicate that the filter is blocked or clogged and is due for maintenance, cleaning, or replacement.

reminder

An overview of the various mechanical pressure switches as well as further technical information can be found on the website. If you have any questions, please feel free to contact us.