pressure transmitters types

There are two-wire and four-wire transmitters, especially two-wire transmitters; there are intelligent and non-intelligent transmitters, and there are more and more intelligent transmitters; there are pneumatic and electric transmitters, and most of them are electric transmitters. ; In addition, there are intrinsically safe and explosion-proof types according to the application;

The main types of transmitters according to the application conditions are as follows:

• Low (micro) pressure/low differential pressure transmitter;

• Medium pressure/medium differential pressure transmitter;

• High pressure/high differential pressure transmitter;

•Absolute pressure/vacuum/negative pressure differential pressure transmitter;

• High temperature/pressure, differential pressure transmitter;

• Corrosion resistance/pressure, differential pressure transmitter;

• Easy to crystallize / pressure, differential pressure transmitter.

Pressure transmitter model selection criteria

The selection of transmitters is usually based on installation conditions, environmental conditions, instrument performance, economy and application media. In practice, it is divided into direct measurement and indirect measurement; its uses include process measurement, process control and device interlocking. Common transmitters include ordinary pressure transmitters, differential pressure transmitters, single flange transmitters, double flange transmitters, plug-in flange transmitters, etc.

Functions of pressure transmitter & DP transmitter

Pressure transmitters and differential pressure transmitters measure the difference between pressure and two pressures, but there are many parameters that they indirectly measure. Like a pressure transmitter, in addition to measuring pressure, it can also measure the liquid level in the device. When measuring the liquid level in an atmospheric pressure vessel, a pressure changer is required. When measuring the liquid level of a pressurized container, two pressure transducers can be used, that is, one for the lower measurement limit and one for the upper measurement limit. Their output signals can be subtracted to measure the liquid level. Generally, a differential pressure transmitter is used. It can also be used to measure the density of the medium when the liquid level and pressure in the container remain unchanged. The measurement range of the pressure transmitter can be very wide, from the absolute pressure of 0 to 100MPa (generally).

In addition to measuring the differential pressure value of the two measured pressures, the differential pressure transmitter can also measure the flow rate with various throttling elements, and can directly measure the liquid level of the pressure vessel and the liquid level of the atmospheric pressure vessel, as well as the pressure and negative pressure.

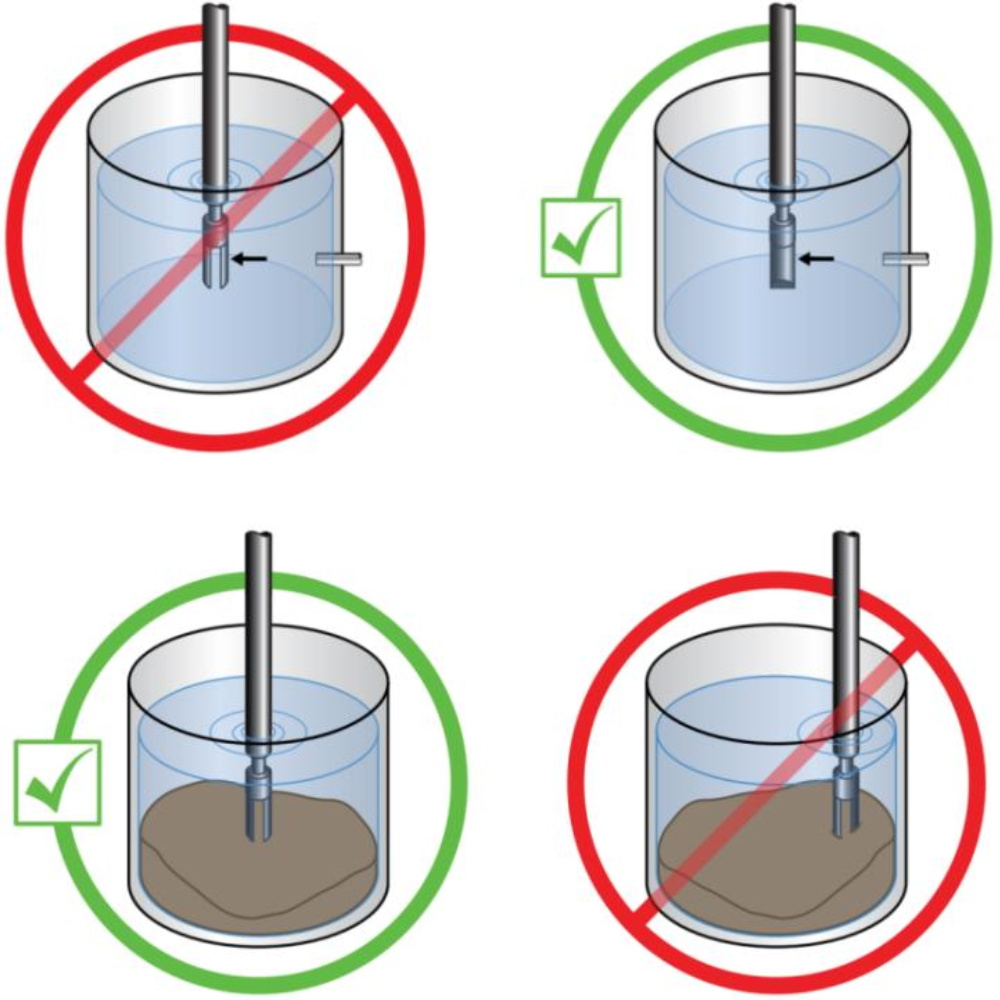

the structure of pressure and differential pressure transmitters

From the structure of pressure and differential pressure transmitters, there are ordinary type and isolation type. There is one ordinary measuring bellows, which directly senses the pressure and differential pressure of the measured medium; the isolated measuring bellows receives the pressure of a stable liquid (usually silicone oil), and this stable liquid is It is sealed between two diaphragms, and the diaphragm that receives the measured pressure is the outer diaphragm. The diaphragm of the original ordinary diaphragm is the inner diaphragm. When the outer diaphragm receives the pressure signal, the pressure of the outer diaphragm is transmitted to the ordinary diaphragm intact through the transmission of silicone oil, and the pressure of the outer diaphragm is measured.