Process Instrumentation For Pharmaceutical Industry

Process instrumentation for the pharmaceutical industry is crucial for ensuring precision, reliability, and quality in the manufacturing process. It plays a vital role in monitoring and controlling various physical variables and converting them into electrical or electronic signals.

Pharmaceutical industry requirements

Quality control and assurance are paramount to ensure the identity and purity of pharmaceutical products, with regulatory compliance being a key requirement for manufacturers.

Safe materials

Specially design for food processing industry with 316L sanitary grade stainless steel wetted material with a roughness of Ra<0.8.

Perfect construction

The process connection parts are all welded and polished as a whole, and the sensor can serve as a hygienic and easily disinfected measuring point.

CIP cleaning

Effective CIP cleaning function, flush surface embedded process interface that can CIP clean almost all chemicals at a temperature of 150 ° C for 2 hours.

Process measuring instruments for pharmaceutical industry

Process measuring instruments play a crucial role in the pharmaceutical industry to ensure quality control, safety, and efficiency in various processes. These instruments are used for monitoring parameters such as temperature, pressure, level, density, liquid component and flow rate. They help in maintaining optimal conditions during food processing, storage, and transportation.

- All

- Pressure

- Level

- Temperature

- Flow

- Component analysis

CIP cleaning

CIP (Clean-in-Place) cleaning is a vital process in the pharmaceutical processing industry that ensures the cleanliness and hygiene of food equipment without the need for disassembly.

Application examples

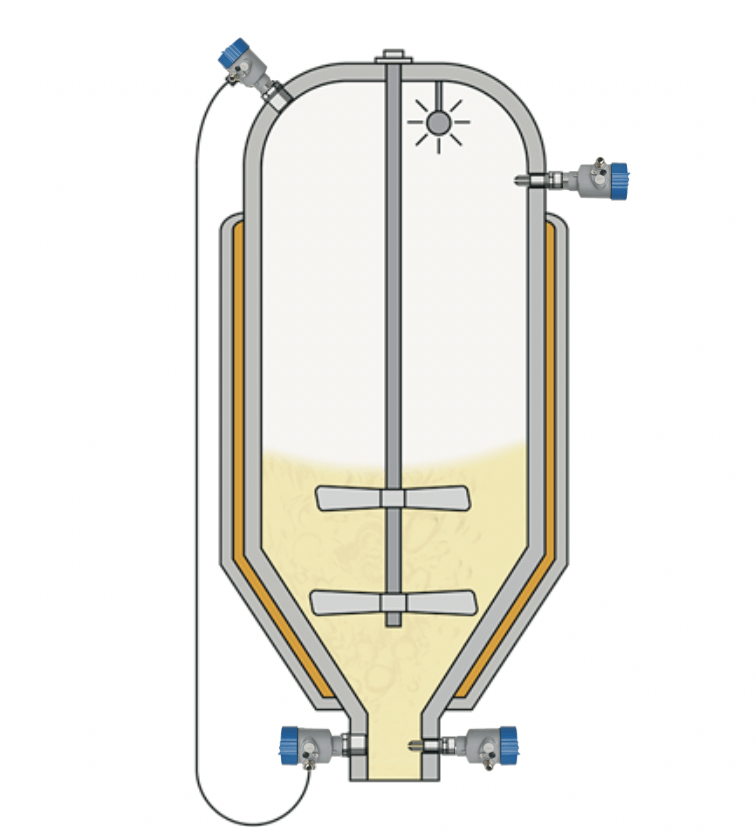

In the biotechnology and pharmaceutical industries, hygiene, replicability, and flexibility are key factors for safe, efficient, and highly automated processing processes. SenTec provides advanced liquid level, pressure, flow rate, and composition analysis measurement technology solutions for this purpose.

Pharmaceutical raw material process

Pharmaceutical processing

Biopharmaceutical Process Analysis

Bring innovation for your cases

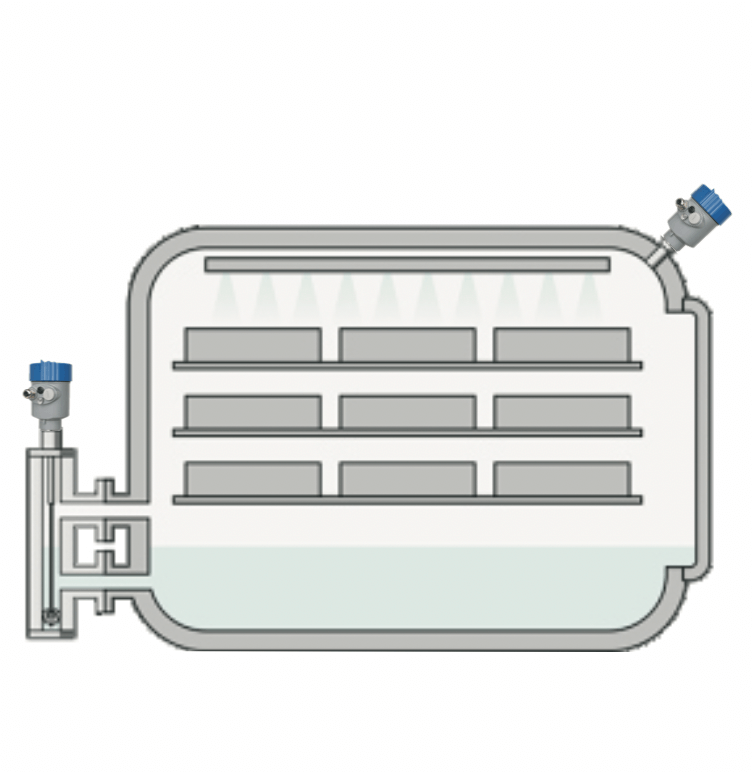

Whether the storage tank is square or cylindrical, independent mobile container or integrated into the production line, large or small, with or without mixing paddles and heating coils: SenTec can provide comprehensive measurement solutions to ensure accurate and safe drug production.

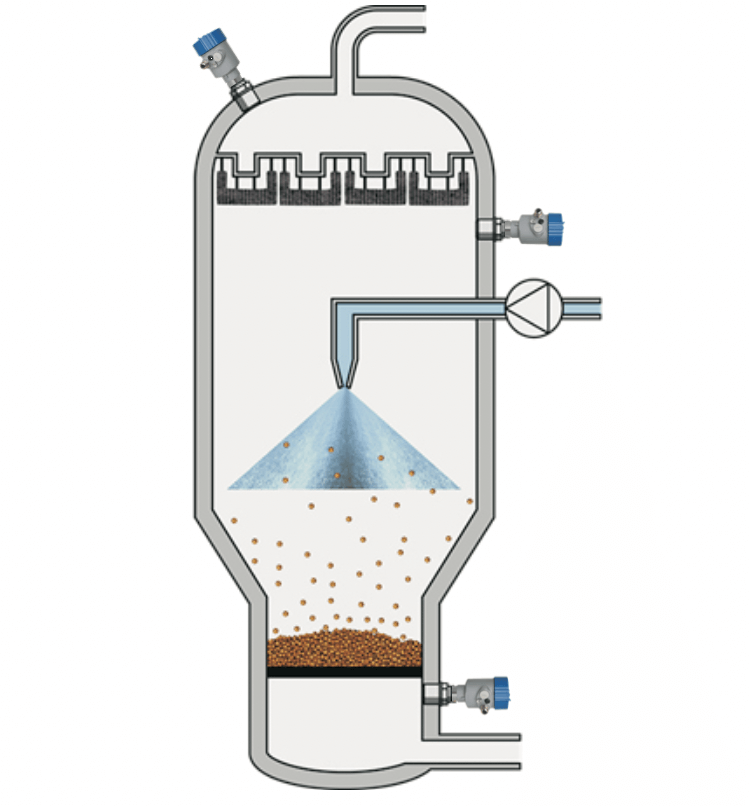

Fluidized bed reactor

Radar level transmitter for continuous level measurement and filter monitoring in granulate production in the fluidized bed reactor

IOT solutions

With its clever networking design and unique services, SenTec process instruments greatly improve the efficiency and security of the entire value creation chain.

Getting started to be Partner with us

Get a Quote

Request a quote from us based on your specific requirements

To be a Distributor

If you want to distribute sentec brand in your local area, you can contact us for more.

Installation & Maintain

A group of professional engineer is here to help your sensor installation & maintenance.