In the era of digital transformation, the world is witnessing the convergence of traditionally separate domains. One such synergy that has gained significant traction is the integration of process instruments with cloud platforms. Process instruments are devices that measure, control, and monitor various parameters like temperature, pressure, and flow in industries. On the other hand, cloud platforms are services that provide computing capabilities and storage space over the internet, thus eliminating the need for physical infrastructures.

Diving deeper into this integrated approach, it becomes evident that the fusion of process instruments with cloud platforms is not just about juxtaposing two domains. Rather, it’s about creating a seamless ecosystem where data from process instruments is collected, stored, and analyzed on cloud platforms. This synergy offers profound advantages including real-time monitoring, remote control, predictive maintenance, and improved decision-making.

Understanding the specifics of cloud platforms and process instruments and how they work together is crucial for businesses that want to stay competitive in the digital age. It is equally important to comprehend how this integration can foster efficiency and productivity, thus driving business growth.

Understanding Cloud Platforms and Cloud Automation

So, what is cloud automation? Cloud automation is the use of tools and technologies to reduce the manual effort associated with managing and provisioning cloud computing workloads. In the context of process instruments, cloud automation can manage the data generated by these devices, analyze it, and make data-driven decisions autonomously, thus reducing human intervention.

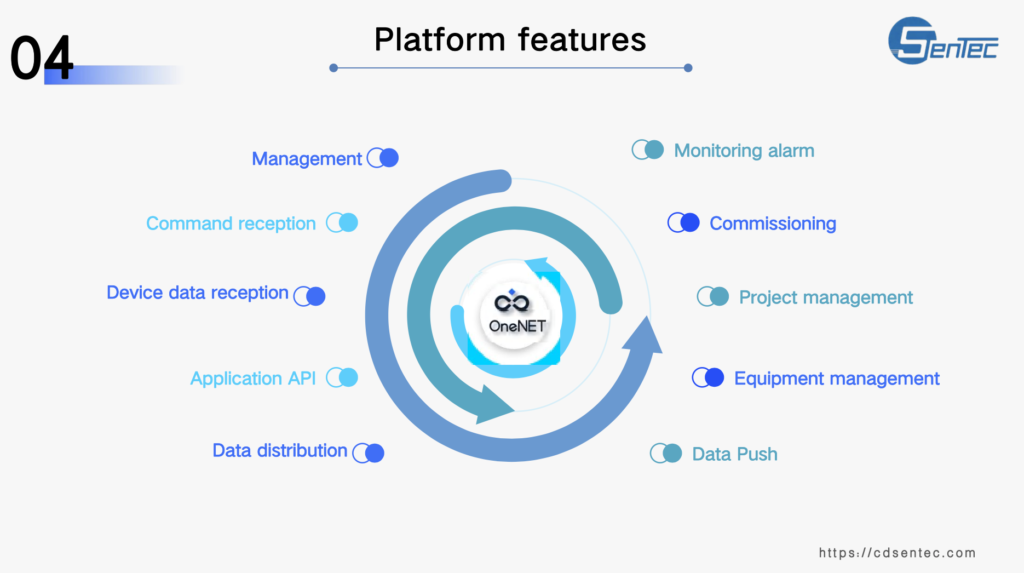

Cloud platforms, a key component of cloud computing, offer a variety of services, such as Infrastructure as a Service (IaaS), Platform as a Service (PaaS), and Software as a Service (SaaS). These services can host, manage, and analyze data from process instruments, thus enabling real-time monitoring and remote control. The scalability, flexibility, and cost-effectiveness of cloud platforms make them an ideal companion for process instruments.

The integration of process instruments and cloud platforms can be a game-changer for businesses seeking to optimize their operations and reduce costs. However, understanding the role of process instruments in plant digitalization is crucial to fully leverage this integration.

The Role of Process Instruments in Plant Digitalization

Plant digitalization, also known as Industry 4.0, is the application of digital technologies to industrial operations. In this context, process instruments play a pivotal role. They are the eyes and ears of the plant, providing real-time data about various operational parameters. This data is the lifeblood of digitalization, driving insights, decisions, and actions.

Learn more by youtube video tutorial:

Process instruments enable plant digitalization in several ways. First, they provide accurate, real-time data, which is crucial for monitoring and controlling operations. Second, they support predictive maintenance by identifying anomalies that could indicate potential equipment failures. Third, they facilitate energy efficiency by monitoring energy use and identifying opportunities for improvement.

However, to fully leverage the potential of process instruments in plant digitalization, it’s essential to measure digitalization with process instruments and cloud monitoring tools.

How to Measure Digitalization with Process Instruments and Cloud Monitoring Tools

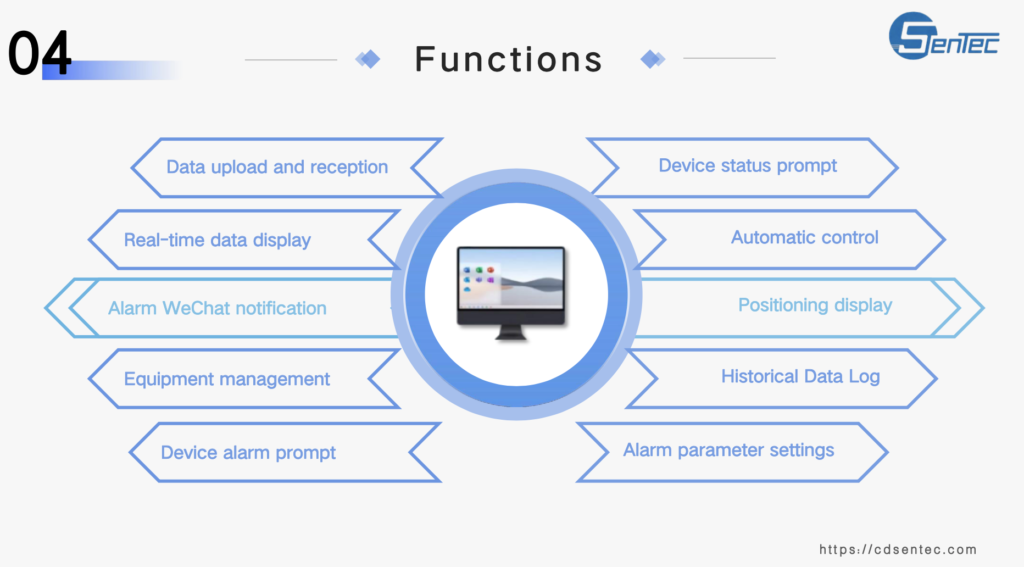

Measuring digitalization involves assessing the extent to which digital technologies are integrated into business operations and how effectively they are used. In the context of process instruments and cloud platforms, this involves using cloud monitoring tools to track and analyze data from process instruments.

Cloud monitoring tools are software applications that track the performance of cloud-based resources. They collect data from process instruments, store it on cloud platforms, and use analytics to derive insights. The insights can reveal patterns and trends, identify anomalies, and provide predictive analytics.

For example, cloud monitoring tools can track temperature data from a process instrument in a manufacturing plant. If the temperature exceeds a certain threshold, the tool can send an alert to the plant manager. The manager can then take appropriate action to prevent equipment damage and downtime.

Benefits of Integrating Process Instruments and Cloud Platforms

The integration of process instruments and cloud platforms offers several benefits. One of the most significant advantages is real-time monitoring. With data from process instruments being continually uploaded to the cloud, businesses can monitor their operations in real-time, identify issues as they arise, and take immediate action. This not only improves operational efficiency but also reduces downtime and maintenance costs.

Another benefit is remote control. With cloud platforms, businesses can control their process instruments from anywhere in the world. This means they can adjust operational parameters, initiate maintenance procedures, and even shut down equipment if necessary, all without being physically present at the plant.

Moreover, cloud platforms offer virtually unlimited storage space. This means businesses can store vast amounts of data from their process instruments, enabling long-term trend analysis and predictive maintenance. In addition, cloud platforms are scalable, so businesses can easily increase their storage space and computing capabilities as their needs grow.

Cloud Monitoring Solutions for Business Efficiency

Cloud monitoring solutions are tools that track the performance of cloud-based resources. As discussed earlier, they collect data from process instruments, store it on the cloud, and use analytics to derive insights. But there’s more to these solutions than just monitoring.

One of the key benefits of cloud monitoring solutions is automation. By automating routine tasks, these solutions free up human resources for more strategic activities. For example, instead of manually checking the status of equipment, plant managers can rely on cloud monitoring solutions to do this and alert them if there’s a problem.

Another benefit is predictive maintenance. By analyzing data from process instruments, cloud monitoring solutions can identify patterns that indicate potential equipment failures. This allows businesses to fix problems before they cause downtime, improving operational efficiency and reducing maintenance costs.

Process Instrumentation and Cloud-Based Automation

Process instrumentation and cloud-based automation are two sides of the same coin. On one side, process instruments provide the data needed for automation. On the other side, cloud-based automation uses this data to drive efficiency and productivity.

Cloud-based automation can manage a variety of tasks, from routine monitoring to complex decision-making. For example, it can automatically adjust operational parameters based on data from process instruments, reducing the need for human intervention. It can also use machine learning algorithms to predict equipment failures and initiate preventive maintenance.

In addition, cloud-based automation can improve business agility. By automating routine tasks, businesses can respond more quickly to changes in market conditions and customer demands. This not only improves operational efficiency but also enhances competitiveness.

When it comes to understanding process instruments and cloud platforms, a PPT can be particularly useful. It can illustrate the architecture of a Process Instrumentation and Cloud-Based Automation.

Insite Connection: A Vital Link in Cloud Application Automation

In the context of cloud application automation, the Insite Connection plays a vital role. It’s a technology that connects process instruments with cloud platforms, enabling real-time data transfer and remote control.

One of the key benefits of the Insite Connection is its ability to integrate with a variety of process instruments, regardless of the manufacturer or model. This means businesses can use their existing process instruments, reducing the need for new investments.

Another benefit is its ability to connect with multiple cloud platforms. This means businesses can choose the cloud platform that best suits their needs, whether it’s Amazon Web Services, Google Cloud Platform, Microsoft Azure, or any other platform.

Cloud Monitoring Software: Maximizing Plant Digitalization Efficiency

Maximizing the efficiency of plant digitalization involves leveraging the full potential of process instruments and cloud platforms. This is where cloud monitoring software comes in. It’s a tool that not only monitors the performance of cloud-based resources but also drives efficiency and productivity.

Cloud monitoring software uses analytics to derive insights from data collected by process instruments. These insights can reveal patterns and trends, identify anomalies, and provide predictive analytics. For example, by analyzing temperature data from a process instrument, cloud monitoring software can predict when a machine is likely to overheat and initiate preventive maintenance.

Moreover, cloud monitoring software can automate routine tasks, freeing up human resources for more strategic activities. It can also improve business agility by enabling rapid response to changes in market conditions and customer demands.

Conclusion: The Future of Process Instruments and Cloud Platforms

The integration of process instruments and cloud platforms is more than just a trend. It’s a paradigm shift that’s reshaping industries and redefining what’s possible. With the ability to monitor operations in real-time, control process instruments remotely, and make data-driven decisions, businesses can optimize their operations, reduce costs, and stay competitive in the digital age.

Looking ahead, the role of cloud platforms and process instruments is likely to become even more significant. As technologies like artificial intelligence and machine learning continue to advance, the potential for automation and predictive maintenance will increase. At the same time, as more businesses recognize the benefits of cloud platforms and process instruments, their adoption will grow.

In conclusion, the integration of process instruments and cloud platforms is not just about maximizing efficiency. It’s about harnessing the power of digital technologies to drive business growth and success in the digital age.