- Tel: +86 28 87436908

- Email: info@cdsentec.com

Process instruments for dairy processing play a crucial role in ensuring the quality and efficiency of the process. SenTec sensors ensure reliable level, pressure, temperature, and flow measurements during the production process of butter, buttermilk, cheese, yogurt products, curds, and whey.

In food industry, milk processing has high hygiene requirements. The raw milk tank, preheater, separator, heat exchanger, homogenizer, etc. in the milk processing process are all designed to measure and control various processes.

The incoming raw milk is stored at a temperature of about 4 °C and stirred gently at all times to ensure it is kept until it is forwarded for further processing. As well as measuring the level in the vessel, the milk is protected against contamination with an overpressure. Point level detection prevents any overfilling of the raw milk tank.

After the raw milk is delivered and stored, it is first preheated to approximately+55 ° C using a preheater, and then transported for separation. To achieve the best heating process, monitor cooling water or hot water by reliably measuring pressure.

After constant temperature treatment of raw milk, it is purified in a separator and separated into cream and skimmed milk. Mix the raw milk and cream again according to the required fat content. To ensure continuous feeding of raw milk to the separator, the pressure is monitored in the feed pipeline of the raw milk. In addition, the pressure is regulated during the separation of skim milk and cream, thus ensuring uniform standardization. Use a limit measuring instrument to monitor solid particles, such as dirt or bacteria, that have been separated and settled below the separator, and control the cleaning process.

In order to prevent the cream from floating to the surface, i.e. the milk fat floating on top of the milk, in the next step, either only the extracted cream or the entire milk will be homogenized. Squeeze cream or milk using nozzles as thin as hair, which reduce the size of fat globules and distribute them evenly in the liquid. Then transfer the homogenized cream back to the skimmed milk. To control the homogenization process, the pressure in the feed pipeline needs to be monitored. At the same time, the piston is best controlled by monitoring the pressure of the hydraulic oil.

These milk process instruments sensors, along with appropriate control systems, enable milk processors to optimize the production process, ensure product quality and safety, and meet regulatory requirements. They also facilitate data acquisition and interpretation, allowing for continuous process improvement and traceability.

Yogurt production is a complex process that involves several steps to ensure the desired quality, consistency, and safety of the final product. Process instruments play a vital role in monitoring and controlling various parameters throughout the production process.

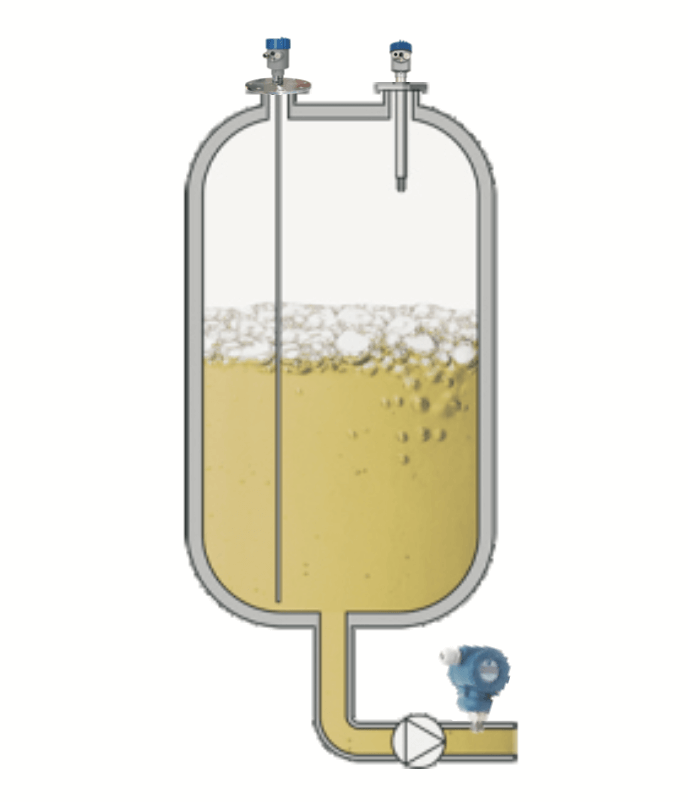

The milk lactose is converted to lactic acid under controlled heating in stirring and batching tanks. This process thickens the milk to yoghurt and gives it its sourish taste. The resulting product is then cooled down. In further processing into a fruit based yoghurt, berries, nuts or grains are added and stirred in. The level and point level detection must be reliably detected to enable optimal filling of the vessel.

Milk and dairy products, such as cream, standard milk, and pasteurized milk, must be stored according to production conditions. Due to the fact that the cream in milk can easily float to the surface even at low temperatures, it is necessary to allow the milk to circulate during storage. The mixing process must not affect the quality of the milk. To ensure that the circulation process is only started after the mixing device is completely covered by the medium, reliable measurements are required.

Yogurt is stored in the storage tank of the filling machine. To achieve the best filling process, it is necessary to reliably measure the liquid level. Limit sensors can prevent dry operation.

Process instruments are essential in yogurt production to monitor and control critical parameters such as temperature, pressure, flow rate, acidity, and texture. By utilizing these instruments, yogurt manufacturers can optimize the production process, ensure product quality and safety, and meet regulatory requirements.

Cheese production involves several key steps in the chemical engineering process. Firstly, raw milk is pasteurized to eliminate harmful bacteria. Then, the milk fat content is adjusted through standardization using membrane filtration.

When producing soft cheese, mix different cheeses into a mixing container and let them melt. Cheese will deposit on the wall of the container and be scraped off there. To ensure continuous production, it is necessary to reliably measure material levels.

The production of dairy culture is a process characterized by heat treatment, cooling, inoculation, cultivation, and storage. Time and temperature conditions must be strictly observed during the production process. In addition, strict prevention of pollution from the outside world is necessary. Reliable measurement of liquid levels and limits is crucial for optimizing the process.

When making cheese, rennet is needed to thicken the milk. Store rennet in a storage tank and add it to the cheese making bucket as needed. To ensure sufficient supply of rennet during continuous cheese production, reliable level and limit measurements are essential.

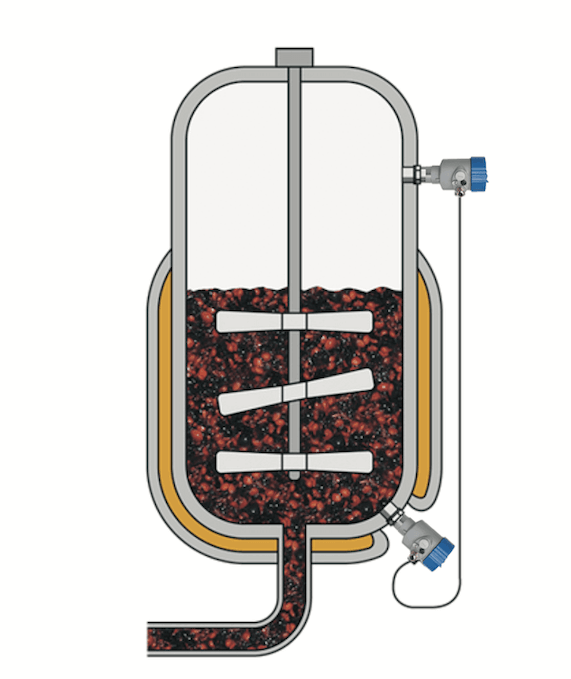

Mix milk with culture and rennet and pour into a cheese tank. Then, the milk coagulates at a constant temperature of+35 ° C. Cut off the curd after it solidifies. Subsequently, the whey is pumped out through a pipeline. Vacuum the curd fragments for further processing. Prevent dry operation by reliably measuring the limit.

The cheese production process instruments play a crucial role in different stages of the cheese production process, from milk processing to final packaging, ensuring consistent and safe cheese production.

CIP (Clean-in-Place) cleaning is a vital process in the milk industry that ensures the cleanliness and hygiene of milk dairy equipment without the need for disassembly.

Condense the pipeline water evaporated in the steam separator in the condenser to pure water. A cooling system is installed in the condenser to cool and condense the steam. The supply of coolant will be monitored in the pipeline. By limiting the measurement, it is ensured that there is sufficient condensate water so that no steam directly enters the circulation of the reserve tank.

In the production process of purified water, tap water is first fed into the steam separator. The tap water evaporates there and is then sent to the condenser. Evaporation is achieved by a heat exchanger that supplies saturated steam. To ensure that the heat exchanger is always flooded with pipeline water, it is necessary to reliably monitor the limit. In order to achieve maximum efficiency, the pressure inside the steam separator must be kept constant.

Purified water is used for CIP cleaning of production equipment. This water is produced through filtration and distillation, and then temporarily stored in a water tank. Absolute sterility and cleaning ability are the main requirements for all instrument components that come into direct contact with the medium. This also applies to measuring instruments for measuring liquid level and pressure in storage tanks.

The process technology equipment in the food processing industry adopts validated “in place cleaning (CIP) The process of cleaning ensures that the production container is in a sterile state. Here, sodium hydroxide solution or concentrated acid is usually used as the cleaning agent, which is stored in the storage tank of the on-site cleaning equipment and diluted in the production container. The storage of the cleaning agent can be best controlled through liquid level measurement. Limit measuring instruments are used to prevent overflow and dry operation.

During the CIP process, various process instruments can be used to monitor and control factors such as temperature, flow rate, and chemical concentration. This ensures that the cleaning solution is effective and that the equipment is thoroughly cleaned.

SenTec online resource library is a place you can know more knowledge from video, cases study, e-book etc.