Ultrasonic flow meters are instruments that measure flow by detecting the effect of fluid flow on an ultrasonic beam (or ultrasonic pulse).

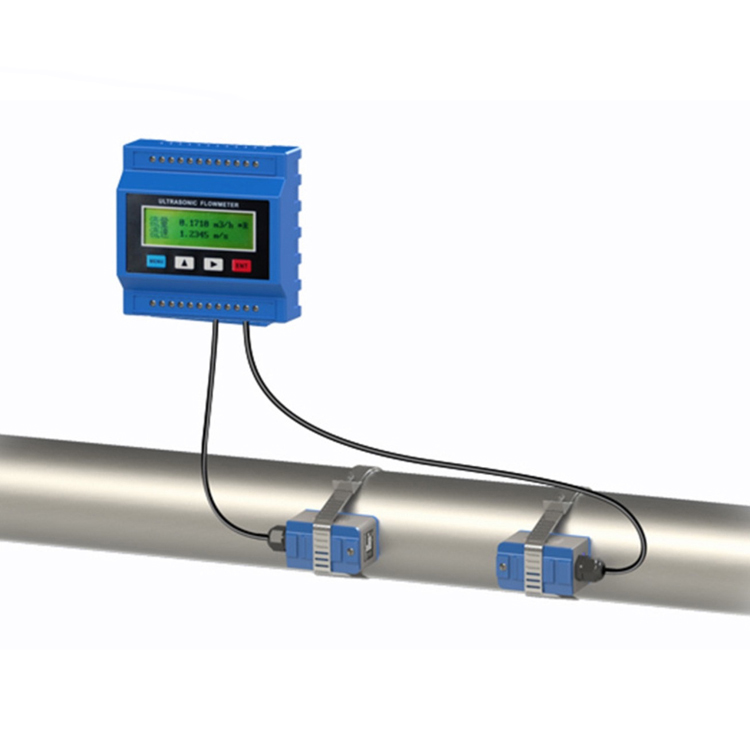

Clamp-on or tube-segment ultrasonic flow meters are based on the principle of “velocity difference method” to measure the liquid flow in a circular tube. It adopts advanced multi-pulse technology, signal digital processing technology and error correction technology, which makes the flow meter more suitable for the environment of the industrial site, and the measurement is more convenient, economical and accurate. The products have reached the advanced level at home and abroad, and can be widely used in petroleum, chemical, metallurgy, electric power, water supply and drainage and other fields.

- Tel: +86 28 87436908

- Email: info@cdsentec.com