Pressure transducers

Pressure transducer definition

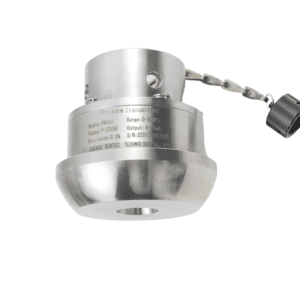

A pressure transducer, also known as a pressure transmitters, is an electromechanical device that accurately measures pressure and converts it into an electrical signal, which can be digital or analog. The output signal is used by controllers, alarms, and other closed-loop systems in various applications, including the oil and gas industry, to monitor and control pressure. There are different types of pressure transducers available, such as strain gauge, capacitance, potentiometric, resonant wire, and inductive pressure transducers, each with unique features designed for specific applications. Proper calibration is critical to ensuring accurate pressure measurement within the specified range.

How do pressure transducers work ?

Super mini pressure transducers 4-20ma adopts high-precision, high-temperature qualitative force-sensitive chip with stainless steel metal diaphragm. After strict precision temperature compensation, signal amplification, V/I conversion, the pressure parameters are reliably converted into industry standard 4 ~20mA or 0~10mA signal output, widely used in petroleum, chemical, metallurgy, electric power, textile, environmental protection and other field.

What does a pressure transducer do ?

Pressure transducers are essential tools in the oil and gas industry for accurate pressure measurement during drilling and production operations.Digital pressure transducers like the

PM430 are commonly used for precision pressure measurement, production testing, calibration, and verification. These transducers help evaluate rock formations, adjust drilling processes, increase well performance, and estimate oil reserves.