Introduction to PT100 Temperature Sensor

Precision temperature measurement is crucial in various industries, from manufacturing to scientific research. PT100 temperature sensor has emerged as a revolutionary technology in this field, offering unparalleled accuracy and reliability. These sensors are widely used to measure temperature in diverse environments, making them an indispensable tool for ensuring product quality and process efficiency. In this comprehensive guide, we will delve into the world of PT100 temperature sensors, exploring their technology, types, advantages, applications, and more.

PT100 temperature sensors are a type of resistance temperature detector (RTD) that operates on the principle of the resistance change of a platinum element with temperature. The “PT” in PT100 stands for “Platinum Temperature,” indicating the material used in the sensor. The “100” signifies the nominal resistance of the sensor at 0°C, which is 100 ohms. This unique characteristic allows PT100 sensors to provide highly accurate temperature measurements across a wide range, making them ideal for critical applications where precision is paramount.

PT100 sensors are available in various configurations, including two-wire, three-wire, and four-wire designs, each offering distinct advantages in terms of accuracy and noise resistance. Understanding the underlying technology of PT100 sensors is essential for harnessing their full potential in temperature measurement applications. By exploring the intricate details of how PT100 sensors operate, users can gain a deeper appreciation for their capabilities and make informed decisions when selecting and utilizing these devices.

Understanding the PT100 Technology

The technology behind PT100 temperature sensors revolves around the intrinsic relationship between the resistance of the platinum element and the temperature of the environment in which the sensor is placed. As the temperature changes, the resistance of the platinum element also varies in a predictable and consistent manner, allowing for precise temperature measurements. This phenomenon is characterized by the sensor’s resistance-temperature curve, which is essential for calibrating and interpreting the sensor’s output accurately.

The platinum element in PT100 sensors exhibits a nearly linear resistance-temperature relationship, especially within the standard temperature range. This linearity is a key advantage, as it simplifies the calibration process and ensures reliable temperature readings across a broad spectrum of applications. Additionally, the stability and repeatability of the platinum element’s resistance make PT100 sensors highly reliable and consistent, even in demanding operating conditions.

Furthermore, PT100 sensors offer excellent long-term stability, maintaining their calibration and accuracy over extended periods. This attribute is particularly valuable in critical applications where temperature fluctuations could have significant ramifications, such as pharmaceutical manufacturing, food processing, and environmental monitoring. By comprehending the intricacies of the PT100 technology, users can harness the full potential of these sensors to achieve precise and reliable temperature measurements in their respective fields.

Different Types of PT100 Temperature Sensors

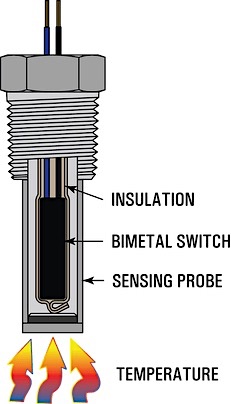

PT100 temperature sensors are available in various types and configurations, each tailored to specific application requirements and environmental conditions. The most common types of PT100 sensors include probe-style sensors, surface-mount sensors, and immersion sensors, each offering unique advantages in terms of installation, response time, and measurement accuracy. Understanding the different types of PT100 sensors is crucial for selecting the most suitable option for a given application.

Probe-style PT100 sensors are the most prevalent type, featuring a slender probe that can be inserted into liquids, gases, or solids for temperature measurement. These sensors are versatile and widely used in industrial processes, HVAC systems, and research laboratories. Surface-mount PT100 sensors are designed to be affixed directly to the surface of an object or component, providing accurate temperature measurements without the need for invasive probes. This type of sensor is ideal for applications where space constraints or surface contact are primary considerations.

Immersion PT100 sensors are tailored for applications that require direct immersion in liquids or aggressive media. These sensors are encased in rugged housings that can withstand corrosive environments, making them indispensable in chemical processing, wastewater treatment, and industrial manufacturing. By familiarizing themselves with the different types of PT100 sensors, users can make informed decisions when selecting the most suitable sensor for their specific temperature measurement needs.

Advantages of PT100 Temperature Sensors

PT100 temperature sensors offer a plethora of advantages that set them apart from other temperature measurement devices. Their exceptional accuracy, stability, and repeatability make them the preferred choice for critical applications where precise temperature control is essential. Moreover, PT100 sensors exhibit excellent linearity and long-term stability, ensuring consistent and reliable performance in diverse operating conditions.

Another key advantage of PT100 sensors is their wide temperature range, which enables them to measure temperatures from as low as -200°C to as high as 850°C, depending on the sensor’s design and construction. This broad range makes PT100 sensors suitable for a vast array of applications, from cryogenic storage to high-temperature industrial processes. Additionally, PT100 sensors are highly resistant to vibration, making them reliable in mechanical and dynamic environments.

Furthermore, PT100 sensors are compatible with various instrumentation and control systems, allowing for seamless integration into existing temperature monitoring and control setups. Their standardized resistance-temperature characteristics facilitate straightforward calibration and interpretation, simplifying the implementation and maintenance of temperature measurement systems. By leveraging these advantages, users can optimize their temperature measurement processes and achieve unparalleled precision and reliability.

Applications of PT100 Temperature Sensors

The versatility and precision of PT100 temperature sensors render them indispensable in a wide range of applications across diverse industries. From industrial manufacturing and energy production to scientific research and medical diagnostics, PT100 sensors play a pivotal role in ensuring optimal process control, product quality, and environmental monitoring. Understanding the varied applications of PT100 sensors is essential for appreciating their widespread impact and potential uses.

In industrial settings, PT100 sensors are utilized for temperature monitoring and control in processes such as chemical reactions, heat treatment, and material testing. Their ability to withstand harsh and demanding conditions makes them ideal for applications in metal processing, glass manufacturing, and semiconductor production. Moreover, PT100 sensors are integral to HVAC systems, refrigeration units, and environmental chambers, where precise temperature regulation is critical for operational efficiency and product integrity.

In the field of scientific research, PT100 sensors are employed in laboratories, environmental chambers, and research facilities to monitor and record temperature variations with utmost accuracy. These sensors contribute to the success of experiments, data collection, and quality assurance in various scientific disciplines, including biology, chemistry, and physics. Medical and pharmaceutical industries also rely on PT100 sensors for temperature-sensitive processes such as sterilization, incubation, and cold chain management, ensuring compliance with stringent regulatory standards.

PT100 vs. PT1000: Choosing the Right Option

When selecting a temperature sensor for a specific application, users often encounter the choice between PT100 and PT1000 sensors. While both types operate on the same principle of platinum resistance temperature detection, they exhibit differences in nominal resistance, accuracy, and response characteristics. Understanding the distinctions between PT100 and PT1000 sensors is crucial for making an informed decision based on the unique requirements of the intended temperature measurement application.

PT100 sensors have a nominal resistance of 100 ohms at 0°C, whereas PT1000 sensors have a nominal resistance of 1000 ohms at the same temperature. This difference in nominal resistance affects the sensitivity and accuracy of the sensors, with PT1000 sensors generally offering higher sensitivity and better resolution for temperature measurements. However, PT100 sensors are more commonly used in industrial applications due to their standardized nominal resistance and widespread compatibility with existing systems.

In applications where precise temperature measurements over a narrow range are critical, PT1000 sensors may offer advantages in terms of resolution and accuracy. Their higher nominal resistance results in a more significant change in resistance per degree of temperature change, making them suitable for high-precision applications such as laboratory research and scientific instrumentation. The choice between PT100 and PT1000 sensors ultimately depends on the specific temperature measurement requirements and the compatibility with existing infrastructure.

Wiring and Installation of PT100 Temperature Sensors

Proper wiring and installation of PT100 temperature sensors are essential for ensuring accurate and reliable temperature measurements. These sensors are available in various wiring configurations, including two-wire, three-wire, and four-wire designs, each offering unique advantages in terms of measurement accuracy and noise resistance. Understanding the principles of wiring and installation is crucial for optimizing the performance of PT100 sensors in diverse applications.

Two-wire PT100 sensors are the simplest in terms of wiring, with the sensor element connected to a measurement instrument using a single pair of wires. While this configuration is straightforward, it can introduce inaccuracies due to lead resistance, especially in long cable runs. Three-wire PT100 sensors mitigate this issue by utilizing a third compensating wire to cancel out the lead resistance, resulting in more accurate temperature measurements. This configuration is commonly used in industrial and laboratory settings where precision is paramount.

Four-wire PT100 sensors offer the highest level of accuracy and noise immunity, as they separate the sensor element’s resistance measurement from the lead resistance. Two wires are dedicated to passing a constant current through the sensor, while the other two wires are used to measure the voltage drop across the sensor element. This configuration effectively eliminates errors introduced by lead resistance, making it suitable for high-precision applications and long cable runs. By understanding the wiring and installation principles, users can select the most appropriate configuration for their specific temperature measurement needs.

Maintaining and Calibrating PT100 Temperature Sensors

Proper maintenance and periodic calibration are essential for ensuring the long-term accuracy and reliability of PT100 temperature sensors. Over time, factors such as mechanical stress, exposure to extreme temperatures, and environmental contaminants can affect the performance of the sensors, necessitating regular inspection and recalibration. Understanding the best practices for maintaining and calibrating PT100 sensors is crucial for maximizing their lifespan and preserving their measurement accuracy.

Routine visual inspection of PT100 sensors is an integral part of maintenance, allowing users to identify any physical damage, corrosion, or contamination that may compromise the sensor’s performance. Cleaning the sensor elements and protective housings with appropriate solvents or cleaning agents helps mitigate the effects of environmental exposure and ensure consistent temperature measurements. Additionally, verifying the integrity of the sensor’s wiring and connections is essential for preventing intermittent faults and signal degradation.

Calibration of PT100 sensors involves comparing their output readings with reference standards and adjusting them to ensure accurate temperature measurement. This process is typically performed using precision temperature sources and calibration equipment that can simulate a range of temperature conditions. By calibrating PT100 sensors at regular intervals, users can verify their accuracy, detect any drift or deviation from the specified tolerances, and make necessary adjustments to maintain their performance within acceptable limits.

PT100 Resistance Chart and Its Importance

The PT100 resistance chart, also known as the resistance-temperature (RT) curve, is a fundamental tool for interpreting the output of PT100 temperature sensors and correlating it with the actual temperature of the measurement environment. This chart provides a graphical representation of the relationship between the sensor’s resistance and the corresponding temperature, allowing users to convert resistance measurements into accurate temperature readings. Understanding the PT100 resistance chart is essential for utilizing PT100 sensors effectively in temperature measurement applications.

The PT100 resistance chart typically depicts the resistance values of the sensor across a wide temperature range, often spanning from -200°C to 850°C. By referencing this chart, users can determine the expected resistance of the sensor at a given temperature and vice versa, enabling them to calibrate, interpret, and validate temperature measurements with precision. The chart’s linear and predictable nature simplifies the conversion process, facilitating accurate temperature readings for diverse applications.

Moreover, the PT100 resistance chart serves as a reference for calibrating and verifying the accuracy of PT100 sensors using known temperature standards. By comparing the sensor’s output resistance with the values indicated on the resistance chart, users can assess the sensor’s performance and make necessary adjustments to ensure its conformity to specified temperature ranges. The importance of the PT100 resistance chart lies in its role as a fundamental tool for understanding and harnessing the temperature measurement capabilities of PT100 sensors.

Conclusion

In conclusion, PT100 temperature sensors have revolutionized precision temperature measurement across a myriad of industries, offering unparalleled accuracy, reliability, and versatility. Their unique technology, diverse types, and myriad advantages make them indispensable for critical temperature monitoring and control applications. By understanding the intricacies of PT100 sensors, including their resistance-temperature characteristics and wiring configurations, users can harness their full potential and achieve precise and consistent temperature measurements.

Whether in industrial processes, scientific research, or medical diagnostics, PT100 sensors play a pivotal role in ensuring product quality, process efficiency, and environmental safety. Their wide temperature range, exceptional stability, and compatibility with various systems make them the preferred choice for temperature measurement in demanding and dynamic environments. Moreover, the PT100 resistance chart serves as a valuable tool for interpreting and validating temperature measurements, further enhancing the reliability and accuracy of PT100 sensors.

As technology continues to advance, PT100 temperature sensors remain at the forefront of precision temperature measurement, driving innovation and excellence in diverse fields. By embracing the capabilities of PT100 sensors and leveraging their advantages, users can elevate their temperature measurement processes and achieve unparalleled accuracy and control. The future of precision temperature measurement is indeed illuminated by the revolutionary technology of PT100 sensors.

CTA:

For more information on PT100 temperature sensors and their applications, contact our team of experts today. Harness the power of precision temperature measurement with PT100 sensors.