Radar measurement technology has revolutionized flow and level metering over the last several years, becoming a radar measurement breakthrough for industries that need precise liquid monitoring. Our research found that there was a way to measure flow without any contact, which works perfectly when sediments are present or when sensors can’t be placed in the medium.

Radar technology brings a significant advantage to level and flow measurement because it doesn’t depend on the medium’s characteristics. Your readings stay accurate regardless of temperature, viscosity, density, or conductivity changes. The flow rate calculation becomes simple with Q = V × A, where velocity and wetted area combine to give you precise results. Mixed frequency radar has revolutionized water system monitoring through integrated flowmeters, which excel in challenging environments.

The FRM Radar Flowmeter stands out as a prime example of this technology. It provides up-to-the-minute data analysis of water flow rate and liquid level around the clock. This device delivers accurate data in complex or harsh environments where standard meters would fail because it uses non-contact radar technology. The device’s value comes from combining flow and level measurement into a single, economical unit that needs minimal upkeep.

This piece explores the inner workings of radar flow meters, from Doppler effect principles to surface velocity measurement. These devices are the foundations of wastewater management, hydrological monitoring, and industrial applications that need reliable measurement without medium contact.

FRM Radar Flowmeter: What It Is and How It Works

The FRM Radar Flowmeter marks a major step forward in hydrological monitoring technology. This advanced device uses multiple radar frequencies to provide accurate and reliable measurements without touching the water.

Non-Contact Mixed-Frequency Radar Explained

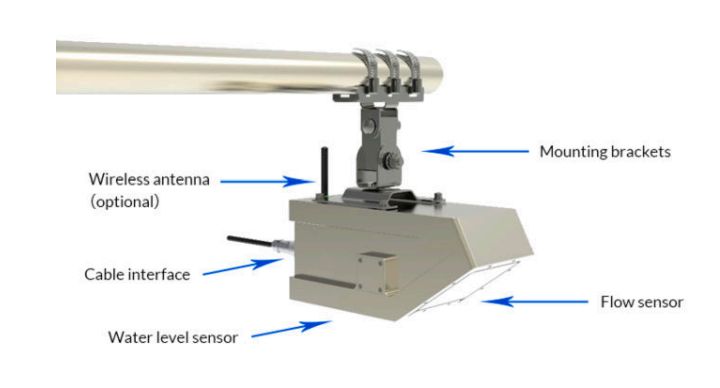

It employs dual-frequency radar technology—24GHz measures velocity while 76-81GHz detects water levels. This combination lets the device track different water parameters at once without signal interference. The velocity radar works on the Doppler principle. It sends electromagnetic waves to the flowing water surface and measures the frequency shift of reflected signals. The high-frequency W-band radar measures the distance to the water surface with ±1mm accuracy.

The device takes all measurements without touching the water. This approach removes the maintenance problems you often see with submerged sensors. The Instruments works better than traditional sensors in water with high sediment loads or chemical contamination.

Flow Rate and Level Measurement Integration

The heart of the FRM6000 combines a radar water level gage and radar flowmeter in one compact unit. The system gathers surface velocity data and works out the average flow velocity through model calculations. It then finds the cross-sectional area by matching water level readings with stored cross-section data.

Ideal Use Cases for FRM Series

The meter’s design makes it perfect for many uses. The meter fits well in hydrology, water conservancy, drainage, and irrigation projects. Its IP68 waterproof rating means it runs reliably outdoors in tough weather.

The system works around the clock and handles rainy conditions. It operates well in temperatures from -35°C to 70°C. The Instruments also performs best in channels where high sediment loads or contaminated water would quickly damage submersed sensors.

The meter’s Modbus RTU protocol support and Bluetooth connectivity blend with its features. These make it perfect for remote sites that need minimal upkeep and steady data flow.

Radar Measurement Principles: From Doppler to Surface Velocity

Radar technology reshapes the scene of water flow measurement by controlling principles of electromagnetic wave reflection. This contactless approach delivers accurate measurements even in challenging conditions where traditional methods fail.

How Radar Detects Flow Velocity

The Doppler effect are the foundations of radar velocity measurement. A radar sensor transmits K-band electromagnetic waves (typically 24 GHz) toward flowing water, and waves reflect off the moving surface with a measurable frequency change. The relative motion between radar and water surface alters the wavelength of returning signals. The detected frequency change increases proportionally with surface velocity, which allows precise velocity calculation. Surface velocity and frequency change maintain a direct proportional relationship.

How Radar Detects Level

Radar systems use a different technique to measure levels. The sensor transmits modulated radar waves (typically in the 77-81 GHz W-band) toward the water surface. Level measurement focuses on the elapsed time between transmission and reception of reflected signals. This time-of-flight principle helps the system calculate the precise distance to the water surface and determine water level. The specialized modulation process ensures these measurements stay unaffected by air temperature, humidity, or other environmental parameters.

Q = V x A: The Core Formula

A simple equation combines velocity and area to calculate flow: Q = V × A. Q represents flow rate, V indicates average velocity, and A denotes cross-sectional area. This straightforward formula underlies all flow meter operations whatever the technology type. The radar system must precisely measure surface velocity and convert it to average velocity. This data combines with level measurements to determine the wetted cross-sectional area.

Simultaneously outputs liquid level, flow rate and flow velocity in multiple frequency bands

Multi-frequency radar systems deliver superior performance by transmitting signals in different frequency bands. This approach enables simultaneous measurement of multiple parameters without interference. Modern flow meters use both K-band for velocity and W-band for level to monitor all required variables with up-to-the-minute data analysis. The dual-frequency technique provides redundancy, and comparisons between different measurements boost overall accuracy and reliability.

Installation, Connectivity, and System Integration

The FRM flow and level meter needs careful attention to physical mounting and communication protocols during field setup. Its design focuses on durability, smooth connectivity, and flexible power options that will give a reliable performance even in tough environments.

IP68 Waterproof Design and Mounting

The Instruments comes with a sealed epoxy body that meets IP68 waterproof rating. This makes it perfect for underwater installation and tough outdoor conditions. You get a standard 15-meter cable, but you can opt for lengths up to 500 meters when you need to place it far from monitoring stations.

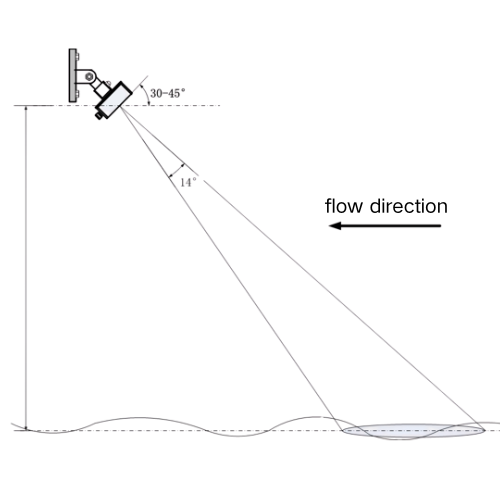

The device offers several mounting choices to fit different setups. Wall mounting works with drill-and-screw flanges, and you can get swivel arms in 140mm or 390mm lengths. Pipe installations use special mounting flanges that work with pipes from 50mm to 275mm in diameter. On top of that, it has rung mounting options for bars between 15mm and 26mm. The radar sensor’s built-in spirit level helps you get the alignment right – a key factor for accurate readings.

Modbus RTU and Bluetooth Debugging

It works with Modbus RTU, the go-to protocol in industrial settings. This popular communication format fits right in with your existing automation and control systems. RS485 connectivity handles data transmission reliably, even over long distances.

The built-in Bluetooth feature makes field maintenance a breeze. Your technicians can connect to the device wirelessly with their phones or tablets to debug, configure, and watch data in real time. They can adjust settings without climbing up to hard-to-reach sensors – a huge plus when meters are mounted high above water or in tricky spots.

Power Supply Options for Remote Sites

Remote installations of the FRM can use different power setups. You can pick from alkaline lantern batteries, D-cell batteries, or special lithium thionyl chloride cells that work great in cold weather. Batteries last anywhere from 8 to 18 months, depending on your sensor type and how often you use it.

The external power setup works with 9-15 VDC inputs. Some models can handle 7-28 VDC, so you can hook them up to solar panels or other power sources. This makes the system perfect for spots where regular power isn’t available.

Conclusion

Conclusion: Advanced Measurement for Modern Water Management

Understanding radar flow and level meter technology shows how it revolutionizes water management in a variety of industries. The FRM Radar Flowmeter shows how non-contact measurement technology solves long-running problems in flow monitoring. Without doubt, this technology works better than traditional submerged sensors, especially with sediment-heavy or chemically contaminated water.

Dual-frequency radar creates a complete monitoring solution that never touches the water. It uses 24GHz for velocity and higher frequencies to detect levels. This setup needs less maintenance and gives more reliable measurements. The system works in extreme temperatures from -35°C to 70°C, making it perfect for any climate.

The reliable IP68 waterproof design helps these devices handle tough environmental conditions. Waterproof construction and flexible mounting options let you place these devices in spots that were hard to reach before. On top of that, it supports Modbus RTU protocol and Bluetooth, which makes it easy to connect with existing systems and maintain in the field.

These advances in radar measurement technology will definitely keep changing how we manage water. The FRM Series shows this progress by combining accuracy, durability, and connectivity in one budget-friendly package. While no measurement system is perfect, radar flow and level meters are a big step forward for industries that need precise, reliable liquid monitoring without direct contact.

Contact us to discuss your needs and obtain solutions.

FAQs

Q1. How does a radar flow meter measure water flow? A radar flow meter emits microwaves towards the water surface. These waves are reflected back, and the device analyzes the frequency shift of the returned signal to calculate the water’s surface velocity. This non-contact method allows for accurate flow measurement without direct contact with the water.

Q2. What are the advantages of using radar technology for water level measurement? Radar technology offers non-contact, continuous measurement of water levels. It’s highly accurate, works in various environmental conditions, and is not affected by temperature, pressure, or vapor density changes. This makes it ideal for use in challenging environments where traditional sensors might fail.

Q3. Can radar flow meters work in contaminated or sediment-heavy water? Yes, radar flow meters are particularly effective in environments with high sediment loads or chemically contaminated water. Since they operate without contact with the water, they avoid issues common to submerged sensors, such as fouling or damage from debris.

Q4. What is the basic principle behind radar level measurement? Radar level measurement uses the time-of-flight principle. The device sends out microwave pulses and measures the time it takes for these pulses to travel to the water surface and back. This time is then used to calculate the distance to the water surface, determining the water level.