In today’s industrial landscape, the need for precise and reliable level measurement in tanks and vessels is paramount. This is where radar level transmitters come into play, offering cutting-edge technology to streamline operations and ensure accurate measurements. In this comprehensive buyer’s guide, we will delve into the world of radar level transmitters, exploring their types, advantages, applications, functionality, and factors to consider when choosing the right transmitter for your specific needs.

Understanding Radar Level Transmitters

Radar level transmitters are advanced instruments used for continuous level measurement in a wide range of industrial applications. They utilize radar waves to determine the level of a substance within a tank or vessel, providing real-time data for monitoring and control purposes. Unlike traditional level measurement methods, radar transmitters offer non-contact measurement, making them ideal for challenging environments where the substance being measured may be corrosive, volatile, or under high pressure.

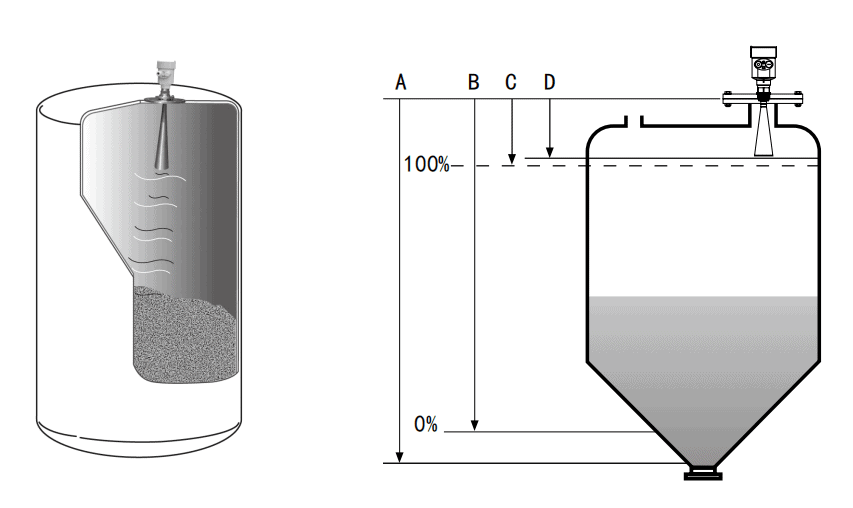

These transmitters operate on the principle of emitting microwave signals towards the substance surface and measuring the time it takes for the signal to be reflected back. By analyzing the time delay and signal strength, radar level transmitters can accurately determine the level of the substance, providing reliable measurements even in harsh industrial settings. With their ability to handle a wide range of temperatures, pressures, and substances, radar level transmitters have become indispensable tools for modern industrial processes.

Radar level transmitters come in various types, each designed to suit specific applications and operational requirements. Understanding the different types of radar level transmitters is crucial for selecting the most suitable solution for your industrial needs. Let’s explore the common types of radar level transmitters and their unique characteristics.

How Radar Level Transmitters Work

Radar level transmitters operate on the principle of emitting microwave radar signals towards the substance surface and measuring the time it takes for the signals to be reflected back. The transmitter antenna directs the radar waves towards the substance, and upon hitting the surface, the waves are reflected back to the antenna. By analyzing the time delay between the emitted and reflected signals, the transmitter can calculate the distance to the substance surface, thereby determining the level with high precision.

The radar signals emitted by the transmitter travel at the speed of light, ensuring rapid and accurate measurements. Advanced signal processing algorithms and digital signal processing (DSP) techniques enable radar level transmitters to filter out interference and echoes, providing reliable level readings even in complex industrial environments. Additionally, the ability to measure levels in real-time and transmit data to control systems or monitoring devices enhances process efficiency and enables proactive decision-making.

When selecting a radar level transmitter for specific operational requirements, it is essential to consider various factors to ensure optimal performance and compatibility with the intended application. Understanding the key considerations for choosing the right radar level transmitter is crucial for making informed decisions in the procurement process.

Types of Radar Level Transmitters

- Guided Wave Radar Level Transmitters: Guided wave radar transmitters utilize a probe that extends into the substance being measured, allowing for precise and reliable level measurements even in challenging conditions such as extreme temperatures, high pressures, or agitated surfaces. The guided wave technology ensures that the radar signal is directed along the probe, enabling accurate measurement of interface levels and overcoming obstacles such as foam or vapor.

- Non-Contact Radar Level Transmitters: Non-contact radar transmitters, also known as “free-space” radar, operate without direct contact with the substance, making them suitable for applications where physical contact is impractical or impossible. These transmitters emit radar signals into the empty space above the substance surface and measure the reflected signals to determine the level, making them ideal for non-intrusive level measurement in various industrial environments.

Advantages of Radar Level Transmitters

Understanding the distinct advantages of radar level transmitters is essential for recognizing their potential impact on industrial operations and processes. Let’s explore the key benefits offered by these advanced level measurement instruments.

- Accuracy and Reliability: Radar level transmitters provide highly accurate and reliable measurements, unaffected by factors such as temperature variations, pressure changes, or the physical properties of the substance being measured. This ensures consistent and precise level readings, vital for efficient process control and inventory management.

- Versatility: Radar level transmitters are capable of measuring a wide range of substances, including liquids, solids, and slurries, making them suitable for diverse industrial applications. Their ability to handle varying dielectric constants and surface conditions further enhances their versatility in different environments.

- Safety and Maintenance: With non-contact measurement capabilities, radar level transmitters eliminate the need for direct contact with the substance, reducing maintenance requirements and enhancing operational safety. They are also unaffected by factors such as dust, vapor, or foam, ensuring reliable performance in challenging industrial settings.

Applications of Radar Level Transmitters

The applications of radar level transmitters span across multiple industries, offering valuable level measurement solutions for diverse operational needs. Understanding the wide-ranging applications of these advanced instruments highlights their significance in modern industrial processes.

- Chemical and Petrochemical: Radar level transmitters are widely used in chemical and petrochemical industries for accurate measurement of liquids, powders, and bulk solids in storage tanks, reactors, and processing vessels. Their ability to withstand corrosive and harsh environments makes them indispensable for ensuring operational efficiency and safety.

- Water and Wastewater Management: In water and wastewater treatment facilities, radar level transmitters play a critical role in monitoring and controlling the levels of water, sludge, and chemicals in various tanks and basins. Their reliable performance and non-contact measurement capabilities make them ideal for these demanding applications.

- Food and Beverage: The food and beverage industry utilizes radar level transmitters for precise measurement of ingredients, raw materials, and finished products in storage silos, tanks, and production vessels. The sanitary design options available for radar transmitters ensure compliance with industry regulations and standards.

Factors to Consider When Choosing a Radar Level Transmitter

Understanding the underlying technology and functionality of radar level transmitters is essential for grasping their operational principles and capabilities. Let’s delve into the working mechanism of radar level transmitters to gain insight into their advanced level measurement techniques.

- Measurement Range: Evaluate the range of level measurement required for your application, considering factors such as tank height, substance volume variations, and operational needs. Select a radar level transmitter with a measurement range that aligns with your specific requirements to ensure accurate and reliable readings.

- Environmental Conditions: Assess the environmental factors within the installation area, including temperature variations, pressure fluctuations, and the presence of vapors or dust. Choose a radar level transmitter that is designed to withstand the environmental challenges prevalent in your operational setting.

- Substance Characteristics: Consider the physical properties of the substance being measured, such as dielectric constant, conductivity, and surface conditions. Ensure that the radar level transmitter is compatible with the substance properties and capable of delivering accurate measurements under varying substance conditions.

Comparing Guided Wave Radar and Non-Contact Radar Level Transmitters

Comparing the features and capabilities of guided wave radar and non-contact radar level transmitters is essential for understanding their respective advantages and suitability for specific industrial applications. Let’s delve into the comparison between these two types of radar level transmitters to gain insights into their unique characteristics.

- Measurement Principle: Guided wave radar transmitters utilize a probe that extends into the substance, allowing for direct measurement of the interface level and overcoming obstacles such as foam or vapor. Non-contact radar transmitters operate without direct contact with the substance, making them suitable for applications where physical contact is impractical or impossible.

- Applications: Guided wave radar transmitters are well-suited for applications requiring precise interface level measurements and overcoming challenging substance conditions. Non-contact radar transmitters excel in non-intrusive level measurement and are ideal for applications with strict hygiene requirements or where physical contact is not feasible.

- Installation and Maintenance: Guided wave radar transmitters require installation of the probe into the substance, which may involve additional considerations for maintenance and cleaning. Non-contact radar transmitters offer the advantage of non-intrusive installation and reduced maintenance requirements, making them suitable for applications with accessibility and cleanliness concerns.

Exploring 80G and 120G Radar Level Transmitters

Exploring the advanced capabilities of 80G and 120G radar level transmitters provides valuable insights into their enhanced performance and suitability for specific industrial requirements. Let’s delve into the features and advantages offered by these high-frequency radar level transmitters to understand their potential impact on operational efficiency.

- High-Frequency Operation: 80G and 120G radar level transmitters operate at higher frequencies, enabling them to deliver superior accuracy and resolution in level measurements. The increased frequency allows for precise measurement of smaller level changes and detection of fine details within the substance being measured.

- Shorter Wavelengths: The shorter wavelengths associated with 80G and 120G radar transmitters enable them to penetrate through vapor, dust, and foam more effectively, ensuring reliable level measurements in challenging environmental conditions. This enhanced penetration capability makes them ideal for applications with potential interference factors.

- Advanced Signal Processing: 80G and 120G radar level transmitters incorporate advanced signal processing algorithms to filter out noise and interference, providing clean and accurate level readings even in complex industrial settings. The digital signal processing techniques employed by these transmitters enhance their performance and reliability in demanding applications.

Selecting the Right Radar Level Transmitter for Your Operations

Selecting the right radar level transmitter for your specific operations involves a comprehensive assessment of technical specifications, operational requirements, and environmental considerations. Understanding the key factors to consider when evaluating radar level transmitters is essential for making informed decisions and optimizing level measurement solutions for industrial processes.

- Application-Specific Requirements: Identify the specific level measurement challenges and operational needs within your industrial setting, considering factors such as substance characteristics, environmental conditions, and measurement range. Choose a radar level transmitter that aligns with the unique requirements of your application to ensure optimal performance and reliability.

- Technical Specifications: Evaluate the technical features and capabilities of radar level transmitters, including measurement range, accuracy, signal processing technology, and communication interfaces. Select a transmitter with specifications that meet the demands of your operational processes and allow for seamless integration with existing control systems.

- Vendor Support and Services: Consider the support and services offered by radar level transmitter vendors, including installation assistance, calibration support, and maintenance provisions. Choose a reliable vendor with a proven track record of customer service and technical expertise to ensure a smooth implementation and ongoing operational support.

Conclusion

In conclusion, radar level transmitters represent a significant advancement in level measurement technology, offering unparalleled accuracy, reliability, and versatility for industrial operations. By understanding the types, advantages, applications, functionality, and selection criteria for radar level transmitters, industrial professionals can make informed decisions to elevate their operations and streamline level measurement processes.

CTA

CTA: For expert guidance on selecting the right radar level transmitter for your industrial operations, reach out to our team of specialists who are dedicated to delivering tailored level measurement solutions. Elevate your operations with cutting-edge radar level transmitters and ensure accurate and efficient level measurement in your industrial processes.