Sensor to measure steam

What Sensor to measure steam? Steam is also known as “water vapor”. Various types of steam are classified according to pressure and temperature: saturated steam, superheated steam. The main uses of steam are heating/humidification; it can also generate power; it can be used as a machine drive. There are many kinds of sensors for measuring steam, such as steam pressure sensor, steam temperature sensor, steam flow sensor, etc.

Table of Contents

Backgroud: Sensor to measure steam

Steam is also known as “water vapor”. Various types of steam are classified according to pressure and temperature: saturated steam, superheated steam. The main uses of steam are heating/humidification; it can also generate power; it can be used as a machine drive. There are many kinds of sensors for measuring steam, such as steam pressure sensor, steam temperature sensor, steam flow sensor, etc.

Steam Pressure Transmitter

A steam pressure transmitter is a device that converts pressure into pneumatic signals or electric signals for control and remote transmission. It can transform physical pressure parameters such as gas and liquid and other physical parameters to standard electrical signals (such as 4~20 mADC, etc.), so as to instruct indicator, alarm, recorder and regulator for measurement, indication and process adjustment.

The steam pressure transmitter is one of the most commonly used sensors in industry practice. It is widely used in all kinds of industrial automatic control environment. It involves many industries, such as water conservancy and hydropower, railway transportation, intelligent building, production automation, aerospace, military industry, petrochemical, oil well, electric power, ship, machine tool, pipeline and so on. The pressure transmitter can be divided into two kind: electric and pneumatic type. The unified electric output signal is 0 to 10 mA, 4 to 20 mA or 1 to 5 V. The aerodynamic uniform output signal is 20 ~ 100 Pa of gas pressure.

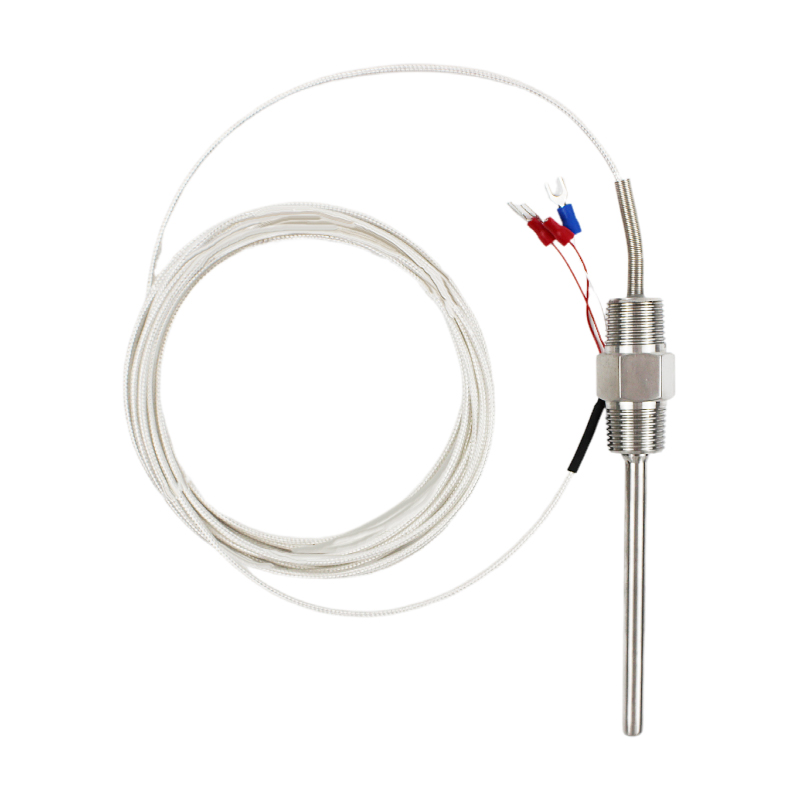

Steam temperature sensor

A sensor that detects steam temperature is called a steam temperature sensor. The steam temperature sensor is composed of a temperature sensitive element and a detection circuit. From the perspective of use, temperature sensors can be roughly divided into two categories: contact type and non-contact type.

According to the mode of the output signal of the temperature sensor, it can be roughly divided into three categories: digital temperature sensor, logic output temperature sensor, and analog temperature sensor.

Subscribe To get new products and solutions

Steam Flow Meter

Vortex flow meter with built-in temperature sensor and pressure sensor to realize vapor mass flow measurement

FMV813 series vortex flow meter now has update with integral temperature and pressure compensation; it does not need any external pressure transmitter, temperature sensor (RTD) also flow computer , which save a lot installation work for the customers. The vortex shedding flow meter digital display can show below information by only one vortex sensor:

*Steam temperature

*Steam pressure

*Steam mass flow (instant flow)

*Steam total mass flow ,steam flow meter with totalizer

It can be made into various process connections for different demands, such as thread, flange, wafer, insertion vortex sensor.

Latest Posts

Dissolved Oxygen Sensor Selection: Proven Tips for Better Water Monitoring Results

Choosing the wrong dissolved oxygen sensor can lead to catastrophic failures: fish suffocating in aquaculture systems or bacteria dying in wastewater treatment plants, halting decomposition.

Clamp-On Ultrasonic Flow Meters: A Practical Guide

Clamp-on ultrasonic flow meters have changed how we measure liquid flow in pipes. These non-intrusive devices provide accurate flow measurements without cutting into existing piping

Underwater Ultrasonic Sensors: Essential Guide for Real Projects

Underwater ultrasonic sensors work reliably in muddy or polluted water where traditional optical methods fail completely. These specialized sensors employ sound waves to detect objects

The Truth About Acoustic Doppler Current Profiler: From Shallow Streams to Ocean Depths

Acoustic doppler current profilers have transformed water movement measurement by capturing data at multiple depths simultaneously, not just at a single point. These sophisticated instruments,