What is the water level sensor?

The water level sensor is an instrument that can convert the water level parameter of the measured point into the corresponding power signal in real time. It is mainly composed of a fully sealed isolation membrane oil-filled sensor and a built-in high-performance microprocessor.

There are many types of water level sensors. There are three common types of ultrasonic liquid level sensors, servo liquid level sensors, and static pressure liquid level sensors. Due to the differences in their working principles and performance, their applications are also different.

What is static pressure liquid level sensor ?

Static liquid level sensor also called Hydrostatic level transmitter which is actually a type of pressure transmitter. Hydrostatic level transmitter is the application of pressure transmitter to liquid level measurement. The submersible Hydostatic pressure level transmitter is based on the principle that the measured liquid static pressure is proportional to the height of the liquid. Piezoresistive effect using diffused silicon or ceramic sensitive elements. Convert static pressure into electrical signal. After temperature compensation and linear correction. Convert to 4-20mADC standard current signal output. In order to achieve liquid level measurement.

High temperature Hydrostatic level sensor Measuring Principle

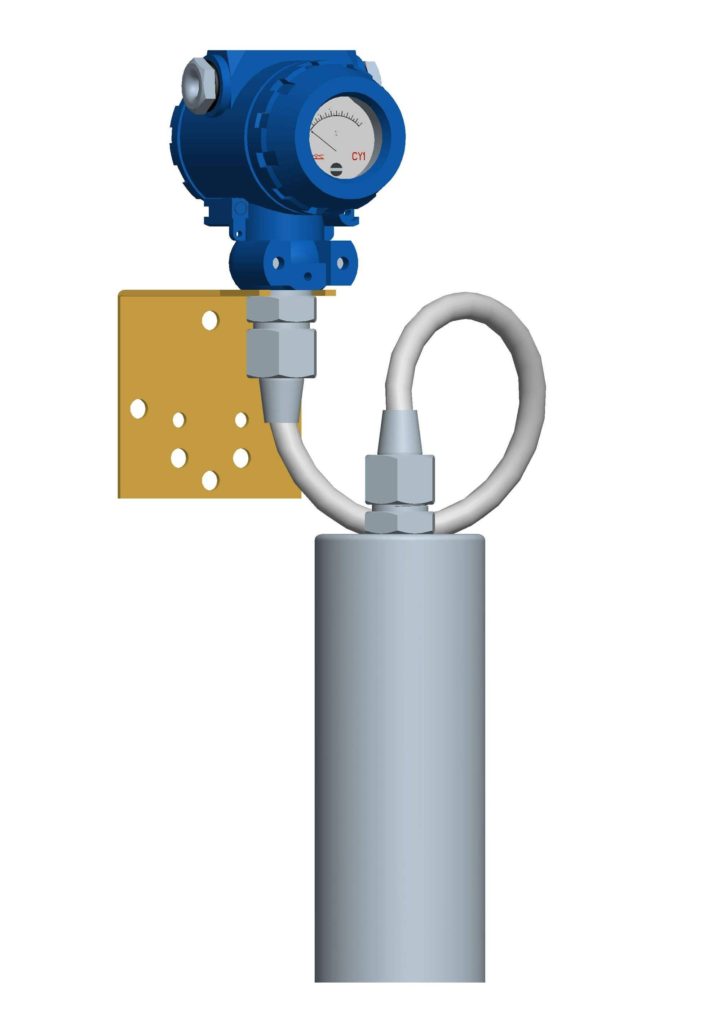

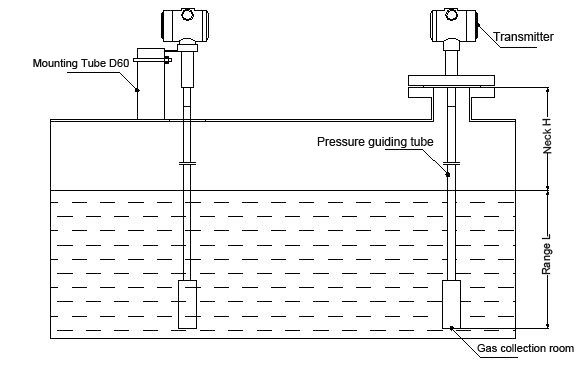

The high temperature pressure guiding liquid level transmitter is composed of the front-end pressure conduction part and the pressure sensing and signal transmission part. The pressure conduction part is composed of stainless steel casing and high temperature pressure guiding pipe, and the pressure sensing part is composed of isolation diaphragm oil-allowing pressure sensor and instrument-specific integrated amplifier circuit.

The product uses the body held in the stainless steel casing to sense and transmit the liquid pressure, and uses the high-temperature pressure guiding tube that allows silicone oil to transmit the pressure to the pressure sensing element, and is equipped with the back-end transmission part to output the standard signal corresponding to the pressure. This product is specially designed for high temperature or strong corrosive liquid, which effectively solves the difficult problem of high temperature liquid level measurement.

What is the high temperature Hydrostatic level sensor advantages and disadvantages ?

A simple analysis for high temperature Hydrostatic level transmitter advantages and disadvantages:

Advantages:

Pressure guide structure, non-contact measurement principle, -30°C~250°C high temperature measuring range; The signal can be transmitted remotely;Suitable for explosion-proof occasions as well. The pressure guiding part is all stainless steel material, high temperature resistant, suitable for compatible high temperature medium level measurement.

Disadvantages:

The transmitter relies on the principle that the compressed air of the air cylinder is transmitted to the pressure sensitive diaphragm to measure the pressure and liquid level. The change of the medium temperature will affect the air compression ratio, which will affect the measurement accuracy. Therefore, the temperature of the medium needs to be kept basically constant. After the temperature changes, the transmitter needs to be taken out of the liquid, the liquid in the gas cylinder is cleaned, the liquid is reinserted, and the measurement will be more accurate.

Installation of high temperature liquid water level sensor

The High temeprature Hydrostatic static pressure liquid level transmitter sensor has two standard installation methods

a.Thread installation

For the transmitter that is directly installed with thread. Generally, there are two ways for installation.

The installation position has thread hole. The liquid level transmitter can be screwed in directly.

If there is no thread hole in the installation position. You can use the existing Φ50 ~ Φ60 light hole, or install a bracket with Φ50 ~ Φ60 hole to Install the liquid level transmitter.

b. Flange mounting

If there are other flange mounting holes in the installation location, please indicate the flange size or the corresponding specifications and standard numbers when ordering.

How to order a high temperature water level sensor

1.The gas cylinder and pressure guiding tube material is usually 304, optional 316L.

2. Please indicate the appropriate measurement range and accuracy requirements when ordering. To ensure product stability and accuracy, it is recommended that the pressure transmitter range be selected based on 120% of the actual measured pressure range. The maximum pressure should be within the measurement range.

3. For medium containing silt sand, the transmitter head needs to take protective measures such as filtering measures to prevent the pressure measuring hole from being clogged or the particles from scratching the diaphragm.

4. When using in hazardous environment such as inflammable and explosive, please install safety barrier according to the regulations. The cable connection should be sealed and reliable. Tighten the junction box cover before powering up to ensure that the transmitter cavity is isolated from the environment. When cleaning, repairing or modifying parameters, the power must be completely removed, the transmitter removed, and moved to a safe environment for processing. On-site live operation is strictly prohibited.

5. Hydrostatic level transmitter price: Sentec, as a manufacturer of Hydrostatic level transmitter, always provides customers with the best Hydrostatic level transmitter price. For the general-purpose Hydrostatic level transmitter or specific high temperature level transmitter, please contact our sales engineer.