which kind of Sensors Applied For Chemical Fiber Industry ?

Which kind of sensors applied for chemical fiber industry ? The high temperature extrusion pressure and temperature sensors are required to be extruded under constant pressure to ensure uniform fiber size. The melt pressure sensor always plays an important role in fiber processing.

Table of Contents

Fiber & textile Backgroud

The full name of chemical fiber is chemical fiber, which refers to the fiber made of natural or synthetic polymer substances as raw materials. According to the different sources of raw materials, it can be divided into man-made fibers using natural polymer substances as raw materials and synthetic fibers using synthetic polymer substances as raw materials.

The original meaning of textile is taken from the general term of spinning and weaving, but with the continuous development and improvement of the textile knowledge system and discipline system, especially after the emergence of technologies such as non-woven textile materials and three-dimensional composite weaving, it is not only traditional hand spinning. And weaving, also including non-woven technology, modern three-dimensional weaving technology, modern electrostatic nano-net technology and other production of clothing, industrial, decorative textiles. Therefore, modern textile refers to a multi-scale structural processing technology of fibers or fiber aggregates.

Process pressure sensors applied for chemical fiber industry

The preparation of chemical fibers is usually first to make a natural or synthetic polymer substance or inorganic substance into a spinning melt or solution, and then filter and measure, and then extrude it from a spinneret (plate) into a liquid stream, and then solidified into fibers. The fibers at this time are called primary fibers, which have poor mechanical properties and must go through a series of post-processing procedures to meet the requirements of textile processing and use. Post-processing is mainly aimed at stretching and heat-setting the fibers to improve the mechanical properties and dimensional stability of the fibers.

In this process, our high temperature extrusion pressure sensor is required to be extruded under constant pressure to ensure uniform fiber size. So, the melt pressure sensor always plays an important role in fiber processing.

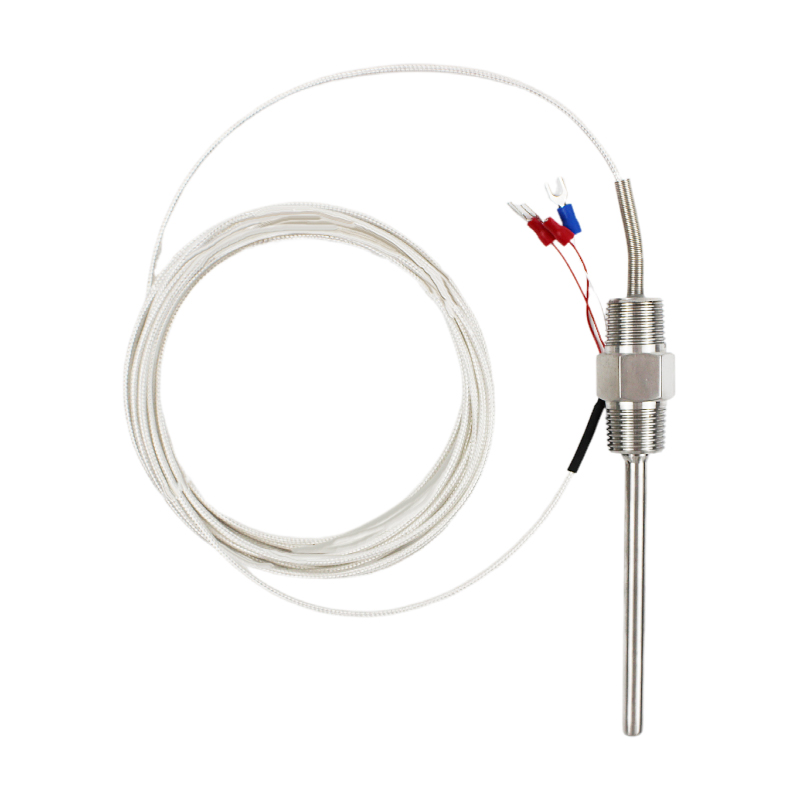

Process temperature sensors applied for chemical fiber industry

The temperature and humidity of the air in the textile mill have a great influence on the production of the textile process, which is due to the alienated connection between the temperature and humidity and the properties of the fibers. When textile machinery processes fibers, each process has different requirements for fiber properties. Therefore, in textile production, temperature and humidity have an estranged relationship with textile process production and have a great impact on product quality. Therefore, it needs to be applied in textile production. Textile-specific temperature sensor and temperature and humidity monitoring system.

Therefore, the control of the temperature of the textile machinery and the temperature and humidity of the textile workshop is the basis for ensuring the stable improvement of product quality and the smooth progress of production. So how do we choose temperature and temperature and humidity sensors? You can choose from the list of products below.

Subscribe To get new products and solutions

Application of photoelectric sensor in textile

Photoelectric sensors are often used in textile machinery and textile production. The photoelectric sensor has the advantages of high precision, fast response, non-contact, etc. Its working principle is based on the photoelectric effect, and its application range is very wide. For example, in the production process of the hot mask machine during the epidemic, a large number of photoelectric sensor equipment was needed. And specific to the textile industry, what are the applications of photoelectric sensors in textiles?

Photoelectric sensor sensor is currently a very wide choice in the detection of yarn breakage detection. In this type of application, photoelectric sensors are mainly used to detect the length of the distance, or to detect the falling of the yarn. There are photoelectric sensor products that ensure reliable use even in dusty or fibrous environments. For example, in use, the photoelectric sensor can successfully capture the momentary signal of the broken yarn falling, and then let the control system process it.

This is because the photoelectric sensor does not change the original turntable of the yarn, and combined with precision machining technology, microscopic technology, and information processing technology, it can realize online monitoring, including cotton fiber detection, weaving, weaving, printing and dyeing, and finishing. Testing, as well as testing in all aspects of subsequent textile production, enables the quality of textile products to be effectively controlled and improved.

For example, in the textile production process, photoelectric sensors are mainly used for speed measurement, removal of yarn defects, detection of yarn hairiness and cloth inspection in the weaving process, printing and dyeing process control and product detection, weft detection and jacquard.

Learn more solutions in chemical industry

Latest Posts

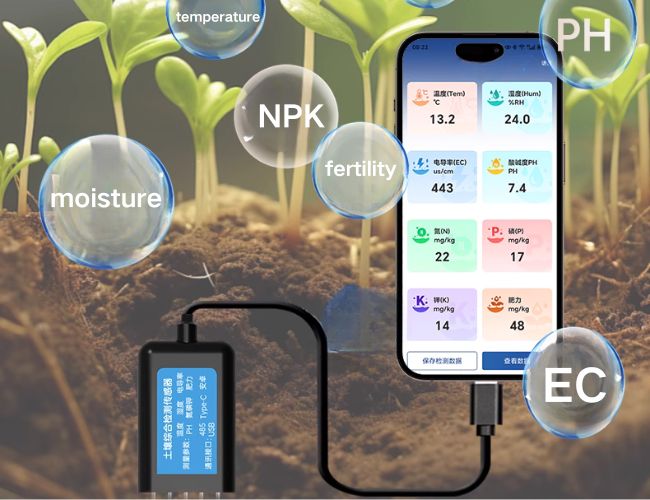

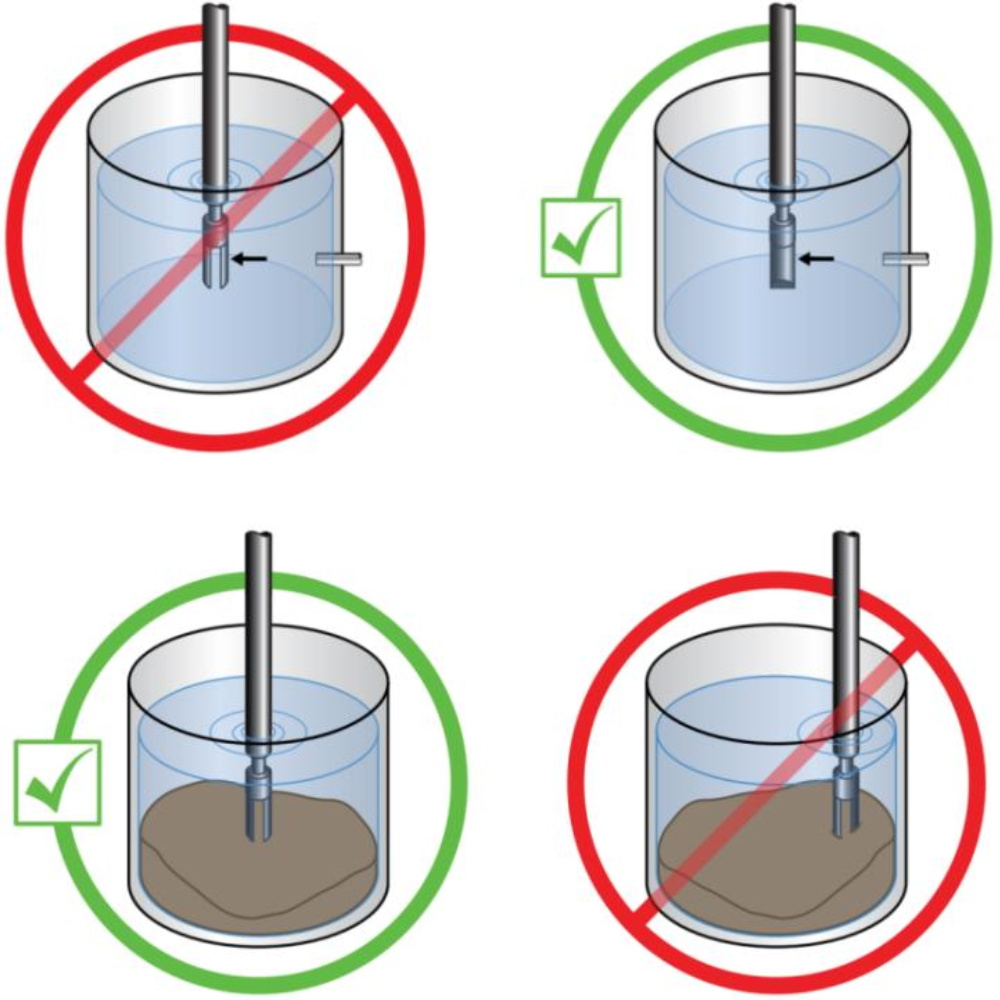

Introducing the Mobile Soil Testing Instrument: Smart, Accurate, and Convenient

The Latest Design of Compact Wireless Temperature and Pressure Sensors: PM451