What kind of sensors used for chemical polymer ?

In the chemical polymer industry, various sensors play a crucial role in monitoring and controlling the production process. These sensors are designed to measure and analyze different variables to ensure the quality and consistency of the polymers being produced.

Table of Contents

Backgroud-sensors for chemical polymer

In chemical industry, chemical polymers are large molecules made up of repeating subunits called monomers. They are widely used in various industries, including plastics, textiles, packaging, automotive, and more. The production of chemical polymers involves complex processes that require precise control and monitoring to ensure product quality and efficiency.

Process instrumentation plays a critical role in the chemical polymer industry by providing accurate measurement and control of various parameters. Here are some sensors commonly used in this industry:

Melt pressure & temperature sensor for plastic chemical polymer

Chemical polymer raw material products are all processed by high-temperature plasticization and extrusion. The solid material is added to the extruder, a commonly used plastic according to different plastic varieties. Control the processing conditions of the extruder to melt and plasticize the polymer. The plasticizing state is an important factor to ensure the quality of the product. This technique can also be used in the extrusion molding of thermosetting plastics.

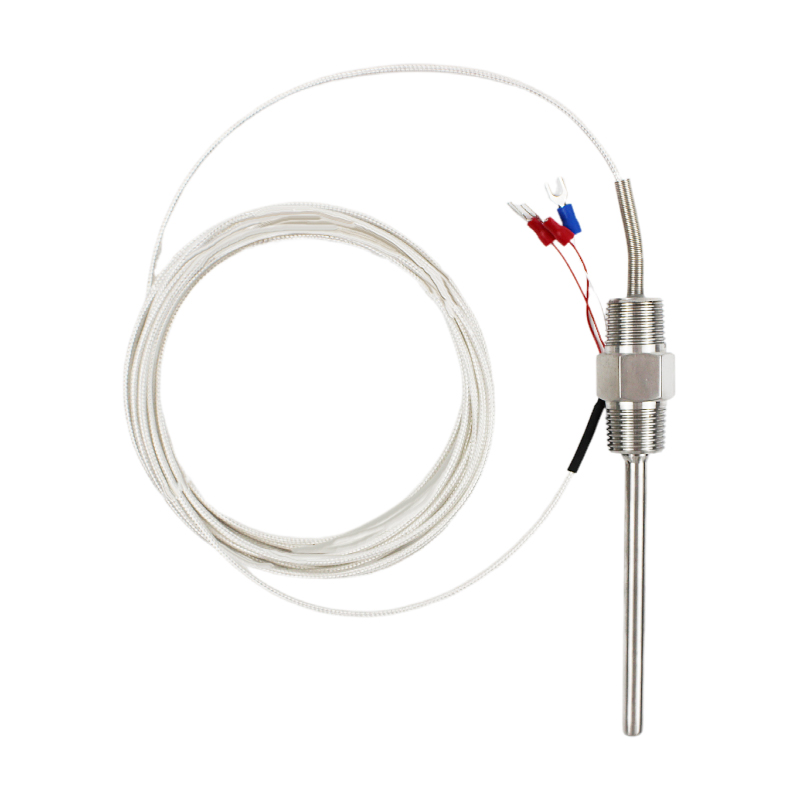

During this process, the plastic extruder uses high temperature extrusion pressure sensors and temperature sensors.

Advantages of SenTec melt temperature and pressure sensors:

✔Military grade high stability core, Stability: ±0.1%FS/year (typical), ±0.2%FS/year (max.)

✔Imported circuit, high-quality measurement accuracy, high accuracy can reach up to 0.5%

✔Anti-jamming design, at least 12 month maintenance free

✔Intrinsically safe explosion, ATEX approved

Plastic chemical polymer powder tank level sensor and point switch

During the storage of plastic powders and masterbatches, there must have the tank powder level sensors and tank point level switch for the tank level monitoring.

Solid Level Sensor/Powder level transmitter types:

✔Radar Level Gauge

✔Ultrasonic Level Gauge

✔RF Admittance Level Meter

✔Heavy Hammer Level Gauge

✔Rotary paddle point level switch sensor

✔Vibration fork point level switch sensor

Subscribe To get new products and solutions

Latest Posts

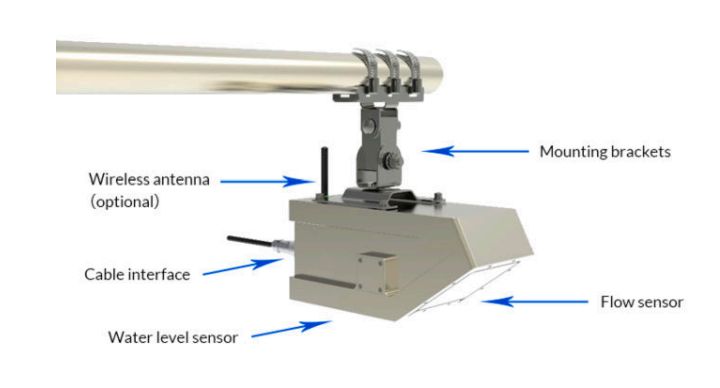

Radar Flow and Level Meter: Which measures water flow rate and liquid level in open channels

Flow Rate and Pressure Relationship Formula: A Simple Guide That Actually Makes Sense